A kind of method of diamond surface nickel plating

A diamond and diamond micropowder technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of high cost, difficult to stabilize process quality, complicated sensitization and activation processes, etc. The effect of reduction, process simplification and stable process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

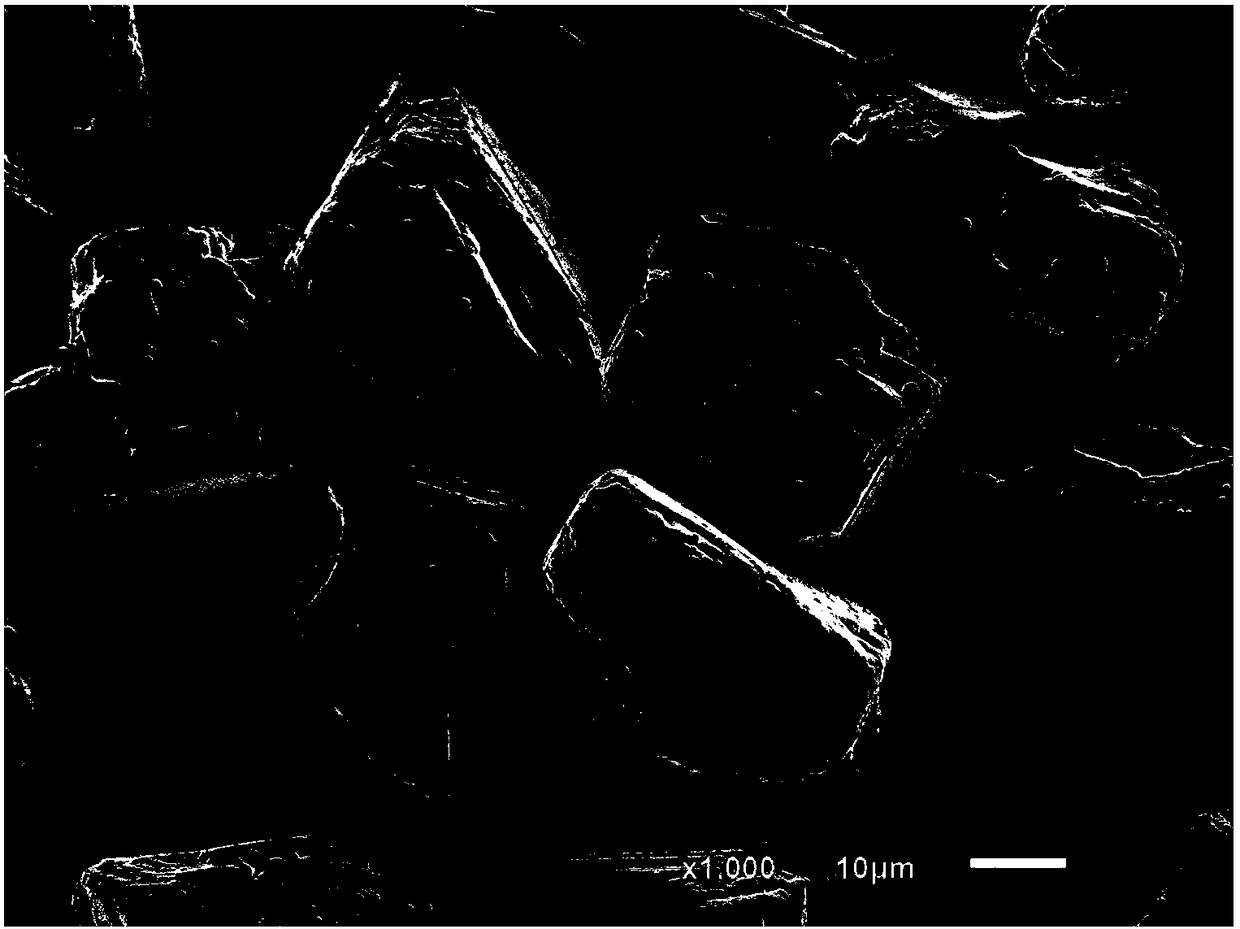

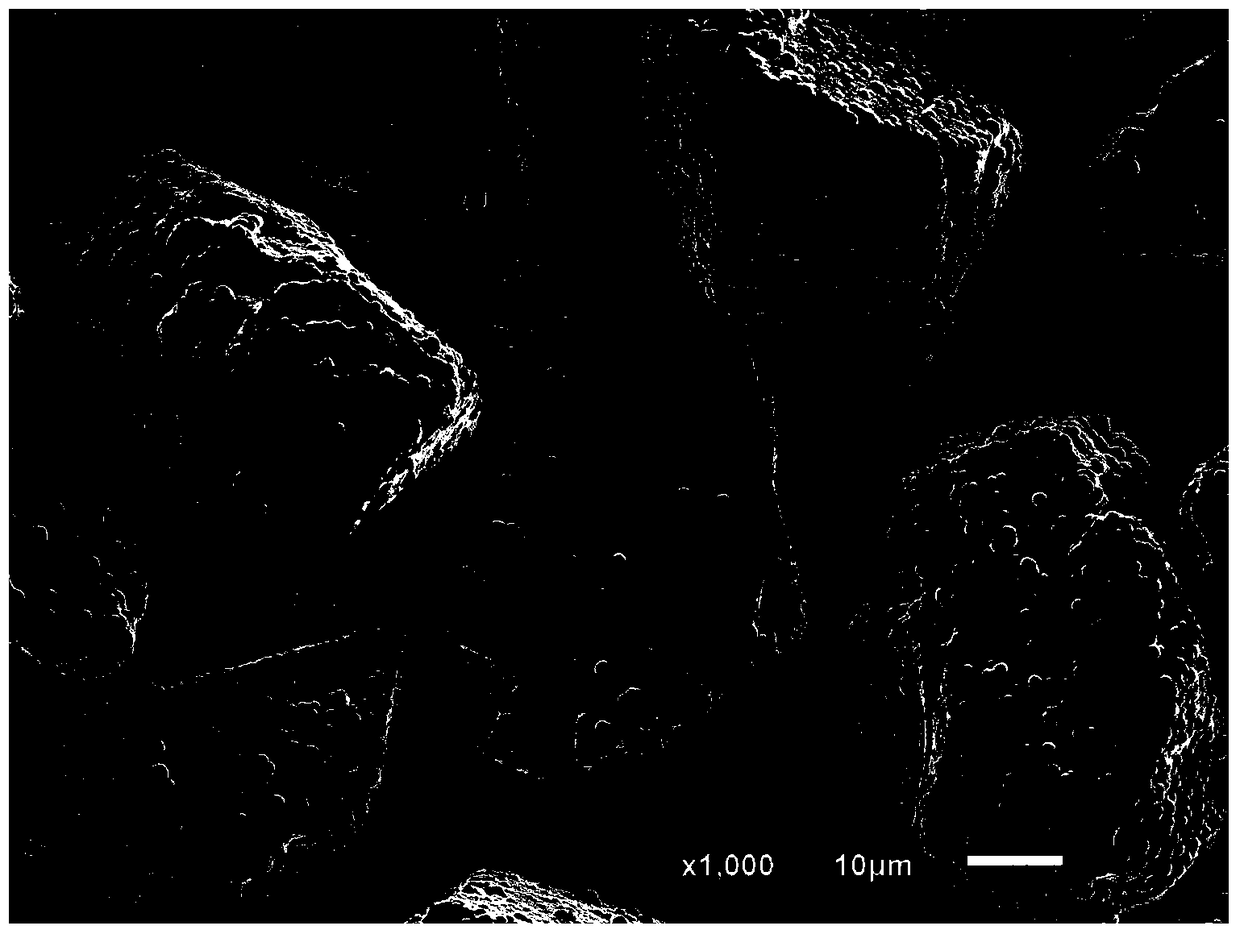

Image

Examples

Embodiment 1

[0042] 1) Soak the diamond micropowder of W40-50 in the degreasing solution to remove the grease and dirt on the diamond surface; wherein, the degreasing solution includes: 10g / L NaOH, 20g / L NaOH 2 CO 3 , 30g / L Na 3 PO 4 12H 2 0, 10g / L sodium silicate and 2g / L emulsifier (sodium lauryl sulfonate); the temperature of the immersion is 20 ℃, and the time is 10min to obtain the diamond after degreasing;

[0043] The degreased diamond is washed with water until the pH value is 6-8 neutral.

[0044] 2) Soak the washed diamond in the activation solution, the activation solution is mainly composed of NiSO 4 50g / L, sodium citrate 100g / L and hydrazine hydrate 50mL / L; the diamond is soaked in the activation solution for 15 minutes, vacuum filtered, and then placed in a vacuum heat treatment furnace for vacuum sintering to obtain activated diamond; , the vacuum pressure of vacuum sintering is -0.06MPa, the temperature is 100°C, and the temperature is kept for 3h.

[0045] The activa...

Embodiment 2

[0049] 1) Soak W30-40 diamond micropowder in a degreasing solution to remove grease and dirt on the diamond surface; wherein, the degreasing solution includes: 10g / L NaOH, 20g / L NaOH 2 CO 3 , 30g / L Na 3 PO 4 12H 2 0, 10g / L sodium silicate and 2g / L emulsifier (sodium lauryl sulfonate); the temperature of the immersion is 30 ℃, and the time is 10min to obtain the diamond after degreasing;

[0050] The degreased diamond is washed with water until the pH value is 6-8 neutral.

[0051] 2) Soak the washed diamond in the activation solution, the activation solution is mainly composed of NiSO 4 100g / L, sodium citrate 200g / L and hydrazine hydrate 100mL / L; the diamond is soaked in the activation solution for 15 minutes, vacuum filtered, and then placed in a vacuum heat treatment furnace for vacuum sintering to obtain activated diamond; , the vacuum pressure of vacuum sintering is -0.08MPa, the temperature is 150°C, and the heat preservation time is 6h.

[0052] The activated diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com