A Dyeing and Finishing Process of Cotton Black Cheese Yarn

A cheese and craft technology, applied in the field of dyeing and finishing technology, can solve the problems of increased consumption, long process flow, and long production process time, and achieve the effects of reducing production time, improving production efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

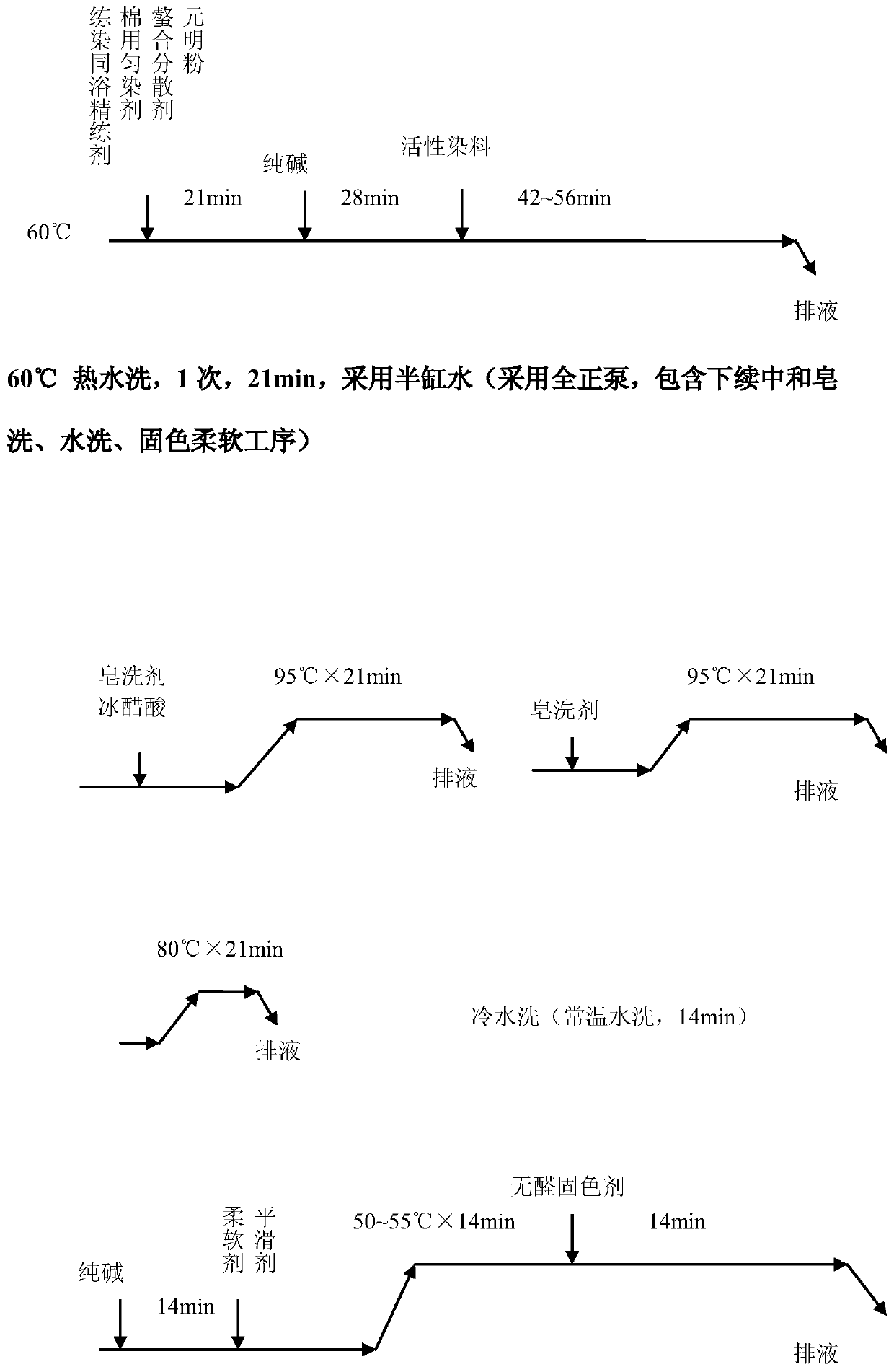

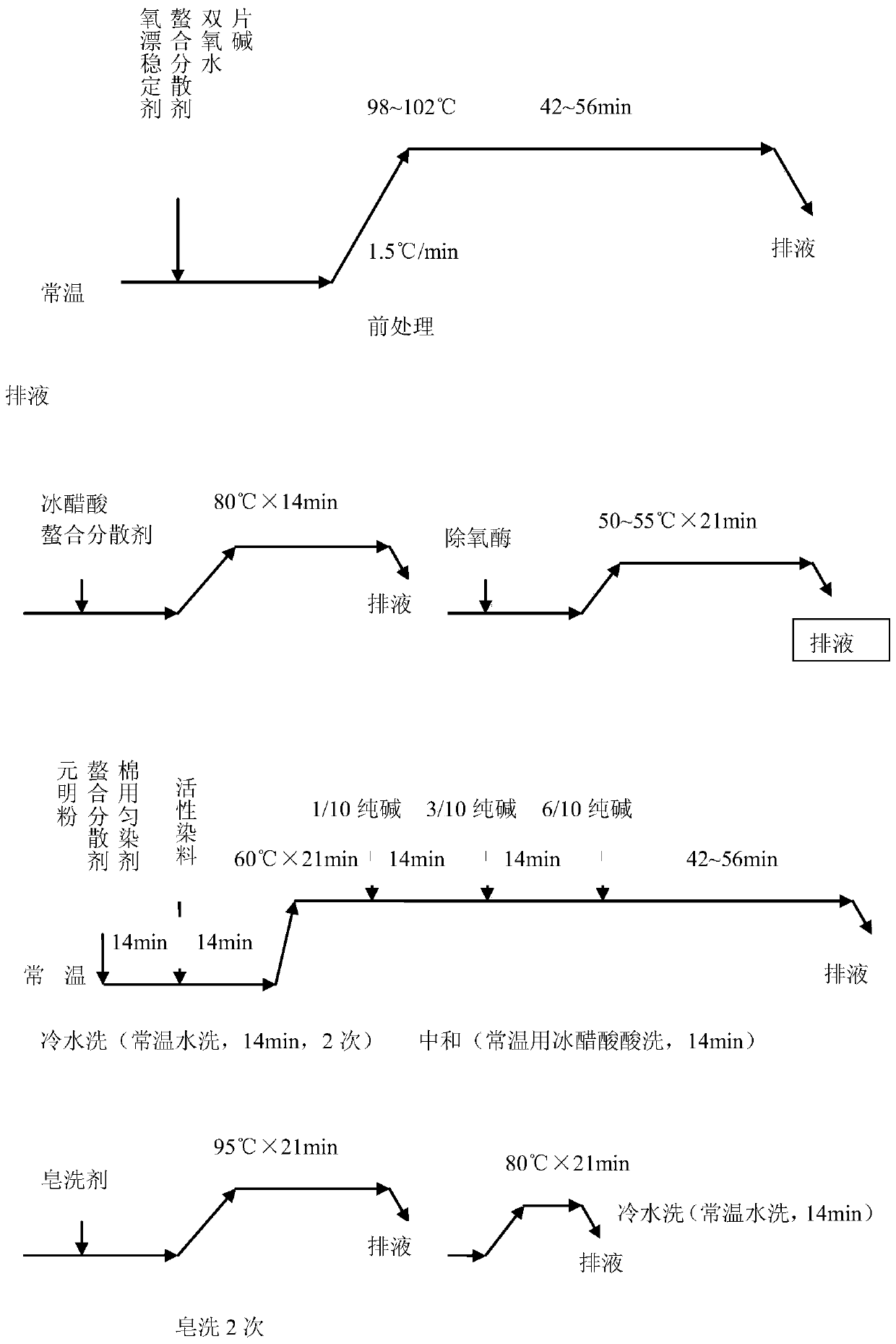

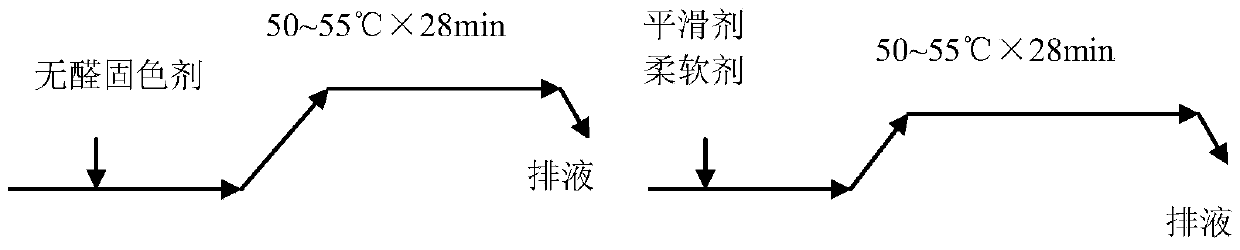

[0018] Embodiment 1: as figure 1 As shown, a dyeing and finishing process of cotton black cheese, the specific process includes the following steps: pre-winding→cage loading→pretreatment, dyeing in the same bath→hot water washing→neutralization, soaping in the same bath→second soaping →Washing in hot water→Washing in cold water→Fixing and softening in the same bath→Inspection→Unloading the cage→Centrifugal dehydration→Drying→Inspection→Packaging;

[0019] Among them, the first tank of water: the pretreatment and dyeing process adopts a constant temperature of 60 ℃, and the whole material method is in the same bath, and the frequency conversion motor of the package yarn equipment operates using positive three reverse four: first hoist the package yarn into the package tank, enter water, and add 90 After ~120g / L Yuanming powder, add 1~2g / L chelating dispersant, 1~2g / L cotton leveling agent and 2~4g / L scouring agent for scouring and dyeing in the same bath, and keep for 21min fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com