High-temperature diamond-impregnated drill bit matrix and manufacturing method of drill bit

A diamond-impregnated, high-performance technology, which is applied in the field of drill bits for processing structural ceramics and its preparation, can solve the problems of reducing the processing efficiency and service life of diamond drill bits, and the inability to maintain the same wear speed of diamond abrasive grains, so as to achieve good wear resistance, Few cracks, the effect of ensuring the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

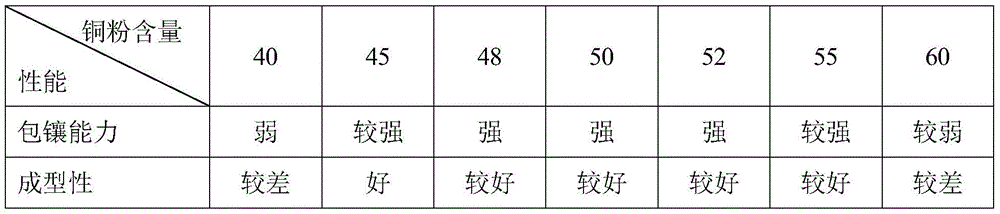

[0022] Raw material: 50 parts of pure Cu powder, 25 parts of pure Co powder, 15 parts of pure Sn powder, 5 parts of pure Ti powder, 5 parts of pure Cr powder.

[0023] Preparation method: (1) Mix the above raw materials to form a carcass, mix the diamond with a concentration of 75% with the carcass, put it into a graphite mold, control the temperature at 660 ° C, and the pressure at 14.7 MPa, and hot-press sintering; when the mixture When it is close to the plastic state, it is pressurized and sintered to form a diamond sintered body; (2) heat the diamond sintered body for 2 minutes, and then cool it to room temperature; (3) after the diamond sintered body is cooled, it is brazed and fixed on the metal substrate. into a diamond drill.

[0024] Here, "diamond with a concentration of 75%" means that the diamond concentration is 75%. The diamond concentration adopts a 400% concentration system, that is, when the diamond concentration is 100%, the diamond volume concentration in ...

Embodiment 2

[0026] Raw material: 45 parts of pure Cu powder, 30 parts of pure Co powder, 12 parts of pure Sn powder, 3 parts of pure Ti powder, 8 parts of pure Cr powder.

[0027] The preparation method refers to Example 1, the difference is that the controlled temperature is 680° C., the pressure is 14.6 MPa, and the holding time is 1.8 min.

Embodiment 3

[0029] Raw material: 55 parts of pure Cu powder, 20 parts of pure Co powder, 18 parts of pure Sn powder, 8 parts of pure Ti powder, 3 parts of pure Cr powder.

[0030] The preparation method refers to Example 1, except that the controlled temperature is 700° C., the pressure is 14.8 MPa, and the holding time is 2.4 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com