Magnetism measuring device, manufacturing method of magnetism measuring device, and manufacturing method of gas cell

A technology of metering device and manufacturing method, applied in magnetic resonance measurement, single-equipment manufacturing, fixed-capacity gas storage tank, etc., can solve problems such as insufficient processing, damage to the airtightness of ampoules, and low evaporation of alkali metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0105]

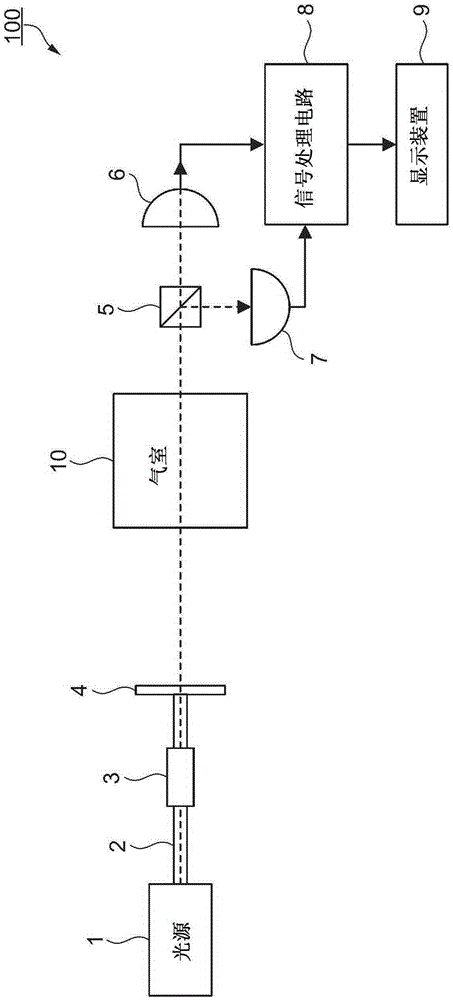

[0106] refer to figure 1 The configuration of the magnetic measuring device according to the first embodiment will be described. figure 1 It is a block diagram showing the structure of the magnetism measuring device of this embodiment. The magnetism measuring device 100 of the present embodiment is a magnetism measuring device using a nonlinear magneto-optical rotation (Nonlinear Magneto-Optical Rotation: NMOR). The magnetic measurement device 100 is used as a living body state measuring device (magnetocardiometer, magnetoencephalometer, etc.) . The magnetic measuring device 100 can also be used in a metal detector or the like.

[0107] Such as figure 1 As shown, the magnetic measuring device 100 includes a light source 1, an optical fiber 2, a connector 3, a polarizing plate 4, a gas chamber 10, a polarized light separator 5, a photodetector (PhotoDetector: PD) 6, a photodetector 7, and a signal processing circuit. 8 and a display device 9 . Alkali metal gas ...

no. 2 approach

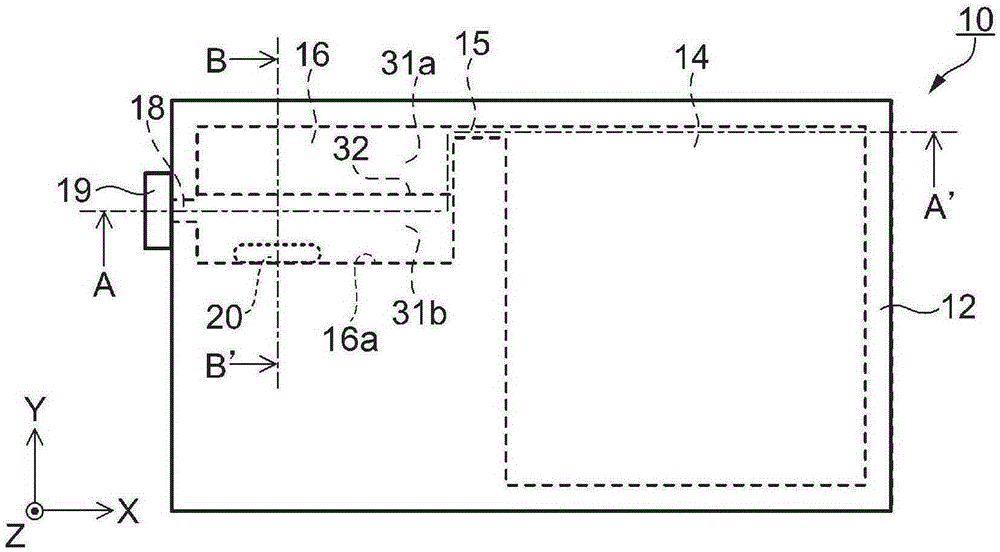

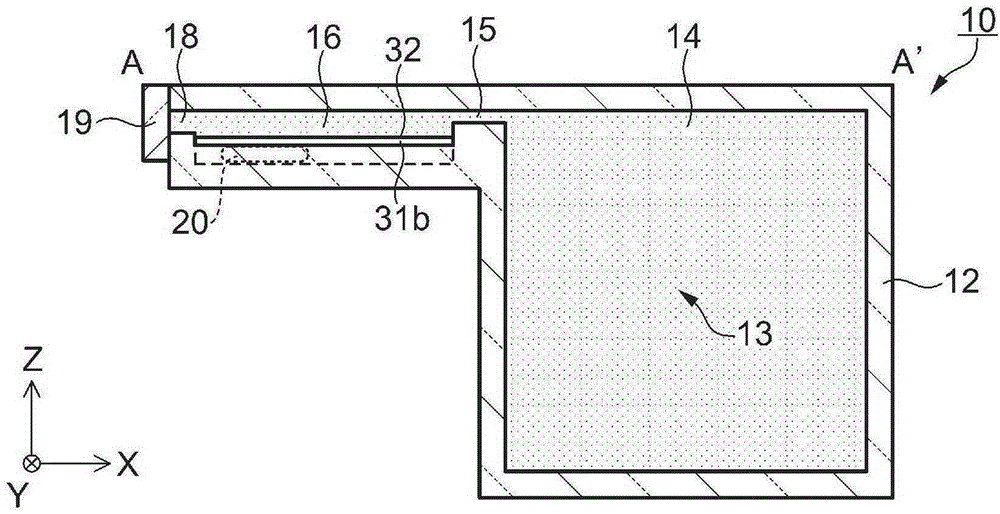

[0160] In the second embodiment, the cross-sectional shape of the storage portion 16 is different from that of the first embodiment in that a concave portion having a valley-shaped cross-section is formed by two inclined surfaces 31a and 31b. refer to Figure 7A , Figure 7B , Figure 7C , Figure 8A as well as Figure 8B Differences between the structure and cross-sectional shape of the gas cell of the second embodiment and the arrangement of ampoules from the first embodiment will be described. In addition, the same code|symbol is attached|subjected to the structural element common to 1st Embodiment, and the description is abbreviate|omitted.

[0161] Figure 7A as well as Figure 7B It is a schematic diagram showing the structure of the gas cell of the second embodiment. Explain in detail, Figure 7A is a schematic top view of the gas chamber, Figure 7B is along Figure 7A A schematic sectional view of the A-A' line, Figure 7C is a partial side view of the gas ...

no. 3 approach

[0174] In the third embodiment, the direction of inclination of the two inclined surfaces of the storage portion is different from the direction of the longitudinal direction of the placed ampoules compared to the first embodiment. refer to Figure 9A , Figure 9B , Figure 9C as well as Figure 9D Differences between the structure and cross-sectional shape of the gas cell of the third embodiment and the arrangement of ampoules from the first embodiment will be described. In addition, the same code|symbol is attached|subjected to the structural element common to 1st Embodiment, and the description is abbreviate|omitted.

[0175] Figure 9A , Figure 9B , Figure 9C as well as Figure 9D It is a schematic diagram showing the structure of the gas cell of the third embodiment. Explain in detail, Figure 9A is a schematic top view of the gas chamber, Figure 9B is along Figure 9A A schematic sectional view of the D-D' line, Figure 9C as well as Figure 9D It is a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com