Double-cathode material and water-based secondary battery

A cathode material and cathode active material technology, which is applied in the field of dual cathode materials and aqueous secondary batteries, can solve problems such as small specific capacity, and achieve the effects of low cost, broad application prospects and high capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

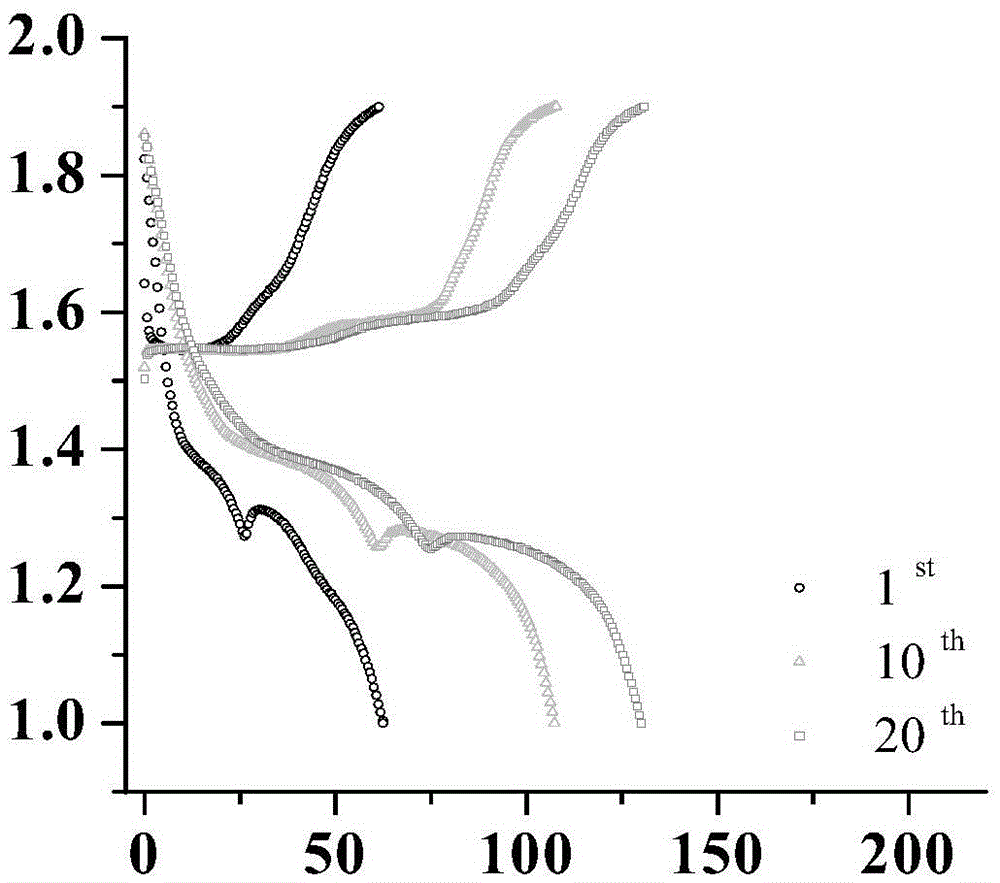

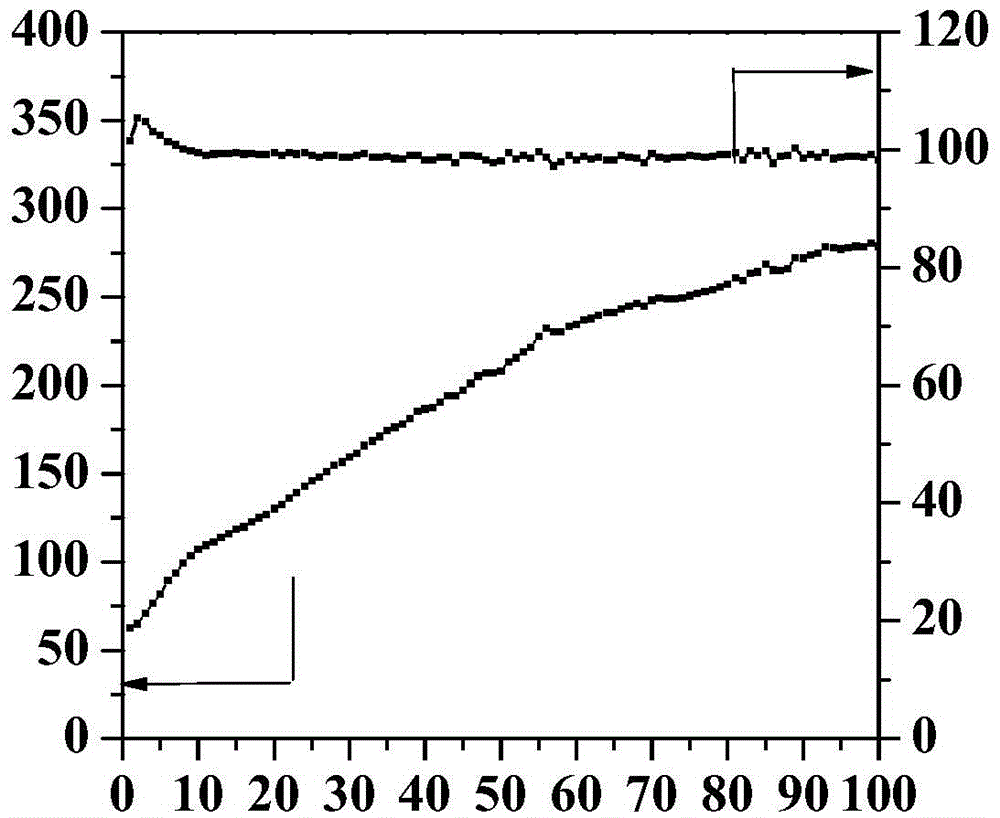

Image

Examples

Embodiment 1

[0031] The molar ratio of Na:Mn is 0.55:1, sodium carbonate (0.055mol) and manganese carbonate (0.1mol) are used as raw materials, blended by ball milling, put into a ceramic boat, and placed in a muffle furnace at 5°C min -1 Heat up to 500°C for 2h, then 2°C·min -1 Raise the temperature to 800°C and sinter for 16 hours to obtain Na 0.44 MnO 2 . The above synthesized Na 0.44 MnO 2 As the active material of the electrode, it is mixed according to the ratio of active material: acetylene black: binder polytetrafluoroethylene at 85:10:5, rolled into a sheet, dried in an oven at 120°C for 12 hours, and cut into 1×1cm 2 , the active substance loading is about 5mg / cm 2 Left and right, the electrodes are made by pressing on the stainless steel mesh with a pressure of 10MPa on the hydraulic press. Na 0.44 MnO 2 The electrode is used as the positive electrode, the zinc sheet with a large excess of active material is used as the negative electrode, and the electrolyte is 0.5molL ...

Embodiment 2

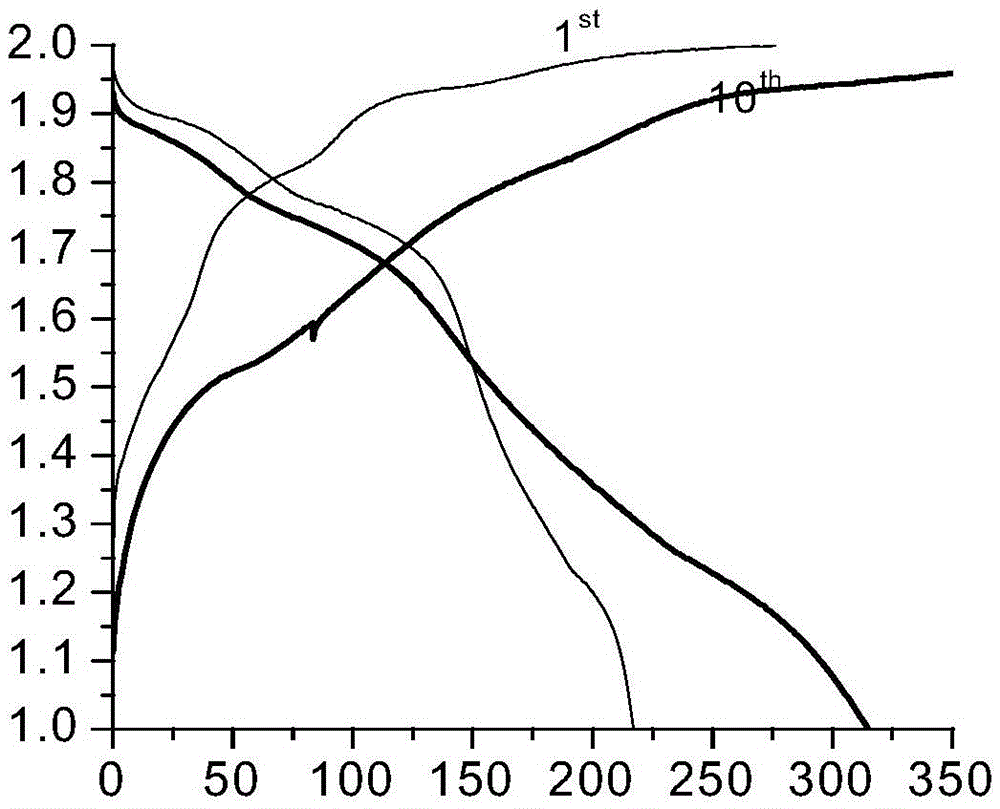

[0033] Using commercial LiMn 2 o 4 As the active material of the electrode, it is mixed according to the ratio of active material: acetylene black: binder of 85:10:5, rolled into a sheet, dried in an oven at 120°C for 12 hours, and cut into 1×1cm 2 , the active substance loading is about 5mg / cm 2 Left and right, the electrodes are made by pressing on the stainless steel mesh with a pressure of 10MPa on the hydraulic press. LiMn 2 o 4 The electrode is used as the positive electrode, the zinc sheet is used as the negative electrode, and the electrolyte is 1molL -1 Li 2 SO4+0.5molL -1 ZnSO4+0.05molL -1 The MnSO4 mixed aqueous solution is assembled into a battery, which is denoted as the second battery Cell2. The second battery Cell2 is at 100mAg -1 (calculate the specific capacity and charge-discharge current density based on the mass of the positive active material) the charge-discharge curve under constant current is as follows image 3 shown. Calculated by the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com