Preparation method of York-shell nitrogen-doped carbon nanocage-coated platinum nanoparticles oxygen-reduction electrocatalyst with high methanol tolerance

A nitrogen-doped carbon and nano-cage technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as complex processes, increased costs, and environmental pollution, and achieve simple technical routes, strong alcohol resistance, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 illustrates the concrete operation method of the present invention

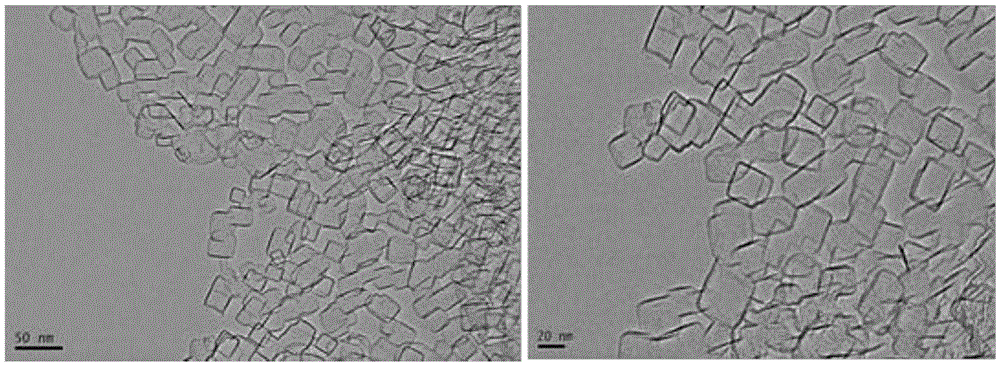

[0036] (1) Weigh 50mg of NCNCs and place it in a vacuum device to evacuate to about 30Pa, add 25ml of 0.01g / ml chloroplatinic acid (it can be one or more mixtures of chloroplatinic acid, sodium chloroplatinate, and platinum acetate) ) in the aqueous solution was stirred for ten minutes, so that the chloroplatinic acid solution was sucked into the cage. Then filter, freeze-dry, then wash off the chloroplatinic acid on the surface with water, then dry, and finally reduce the washed and dried product for 2 hours at 300°C (generally 300-800°C) in a hydrogen atmosphere, and analyze and detect. The particle size of Pt metal nanoparticles in the thus prepared PtNCNCs catalyst is about 1-5nm, and the Pt content is 2.50w.t.%.

[0037](2) Weigh 50mg of NCNCs and place it in a vacuum device to evacuate to about 30Pa, add 25ml of 0.02g / ml chloroplatinic acid (it can be one or more mixtures of chlorop...

Embodiment 2

[0051] Embodiment 2 illustrates the performance of the catalyst prepared by the present invention

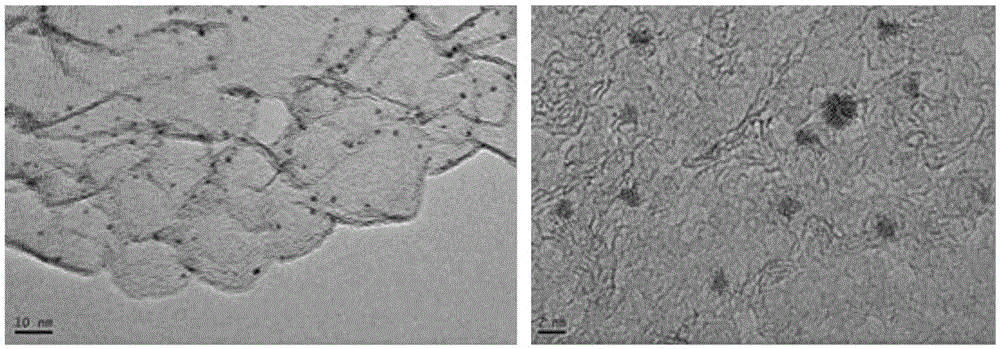

[0052] (1) In 0.5M sulfuric acid electrolyte, CV and RDE experiments of PtNCNCs, Pt / NCNCs and commercial Pt / C were carried out. The experimental results showed that compared with the catalyst loaded on the surface with the same Pt loading, the PtNCNCs prepared by this patent The catalyst is later in the peak potential, and the limiting potential current is slightly lower, showing the difference between Pt on the outer surface and inner surface of the carbon support. see attached image 3 .

[0053] (2) The stability test of Pt / NCNCs and PtNCNCs in 0.5M sulfuric acid was carried out for 80,000 seconds. The comparison charts of CV and RDE before and after show that the catalyst prepared by this patent has excellent stability.

[0054] (3) Add 5% methanol to 0.5M sulfuric acid electrolyte, conduct CV and RDE experiments, and compare with CV and RDE without adding methanol. Exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com