Coated seed manufacturing method and coated seed prepared by coated seed manufacturing method

A manufacturing method and technology of coating seeds, applied in the fields of seed coating/seed dressing, botany equipment and methods, chemicals for biological control, etc. It achieves the effects of excellent physical binding force, hair root improvement, operability and economical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

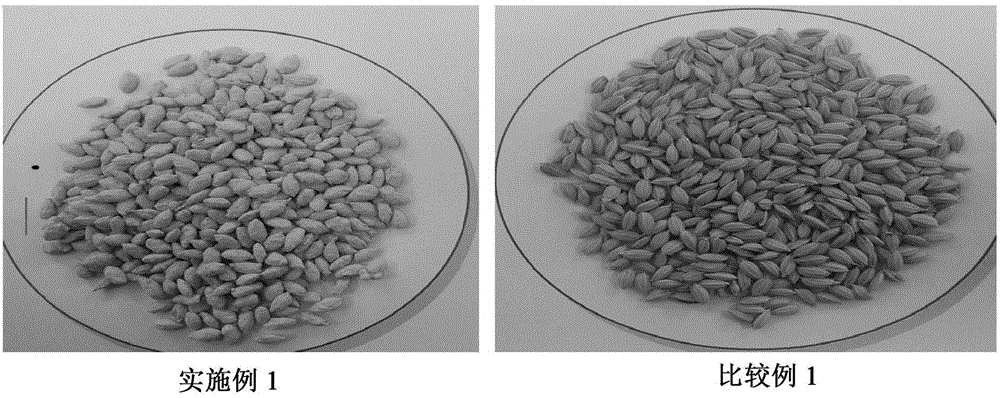

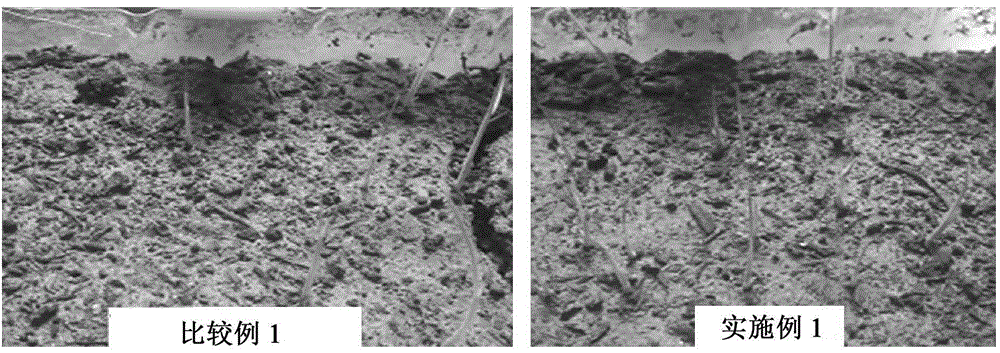

Embodiment 1

[0092] (1) Rice seeds: using an awner to remove awns from rice seeds, dry them, and prepare them for storage.

[0093] (2) Manufacture of binder: Put the powdered humic acid into 80°C ultrapure water, dissolve it by stirring, and leave it for 10 days to fully ferment it. A carboxymethylchitosan (carboxymethylchitosan) solution was mixed with the humic acid solution after fermentation, stirred, and then fermented while stirring for 2 days to prepare a mixed solution of humic acid and chitosan. A certain amount of ultrapure water was added to the mixed solution produced above, stirred, and filtered to remove air bubbles. Thereafter, liquid silicic acid, sodium alginate (sodium alginate) and water-soluble molybdenum were mixed with the filtered mixed solution while stirring at a speed of 15 RPM to manufacture a binder. The content of each component is, relative to the total weight of the binder, containing 10% by weight of liquid silicic acid, 0.5% by weight of chitosan, 8% by w...

Embodiment 2

[0100] It was manufactured in the same manner as in Example 1, except that soybeans were used instead of rice seeds to form a coating layer.

experiment example 2

[0108] Experimental example 2: Investigation of the establishment rate of coated rice seedlings related to soaking time

[0109] The rice seeds of Example 1 and Comparative Example 1 produced as described above were prepared and cultivated in the glasshouse of Gyeonggi-do Institute of Agricultural Technology. In each test garden, 10 coated rice seeds were sown on the left side, and 10 common rice seeds were sown on the right side, and 6 gardens were prepared in total. The 6 gardens were soaked in water for 1 day, 3 days, 6 days, 9 days, 12 days, and 14 days respectively, and were cultivated for 24 days under the condition of 20°C to 25°C to investigate the establishment rate of seedlings and record them in the table below 2.

[0110] 【Table 2】

[0111] As shown in Table 2 above, compared with the common rice seeds of Comparative Example 1, the coated rice seeds of the present invention have significantly better seedling establishment rate.

[0112]

[0113]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com