Biological scaffold manufacturing method based on 3D printing and biological scaffold

A bio-scaffold and 3D printing technology, applied in the direction of digital output to printing unit, drug delivery, pharmaceutical formulation, etc., can solve the problems of single micropore, repetitive structure, unfavorable cell growth, etc., achieve simple and fast production method, and meet production needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a method and system for manufacturing biological scaffolds based on 3D printing. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

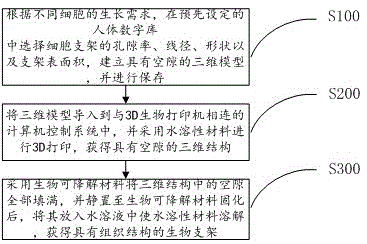

[0028] Such as figure 1 Shown, the present invention provides a kind of bioscaffold manufacturing method based on 3D printing, and it comprises the following steps:

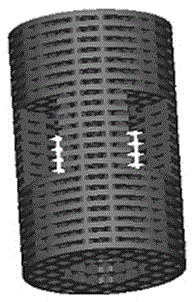

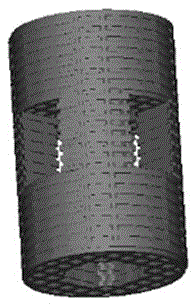

[0029] S100. According to the growth requirements of different cells, select the porosity, wire diameter, shape and surface area of the cell scaffold in the preset human body digital library, establish a three-dimensional model with pores, and save it;

[0030] S200, importing the three-dimensional model into a computer control system connected with the 3D bioprinter, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com