Welding device for high-temperature superconducting coating strip joint with extremely low resistance

A welding device and high-temperature superconducting technology are applied in the field of welding stations for high-temperature superconducting coated strips and welding stations for joints of high-temperature superconducting coated strips, so as to improve welding quality and efficiency, simple structure and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

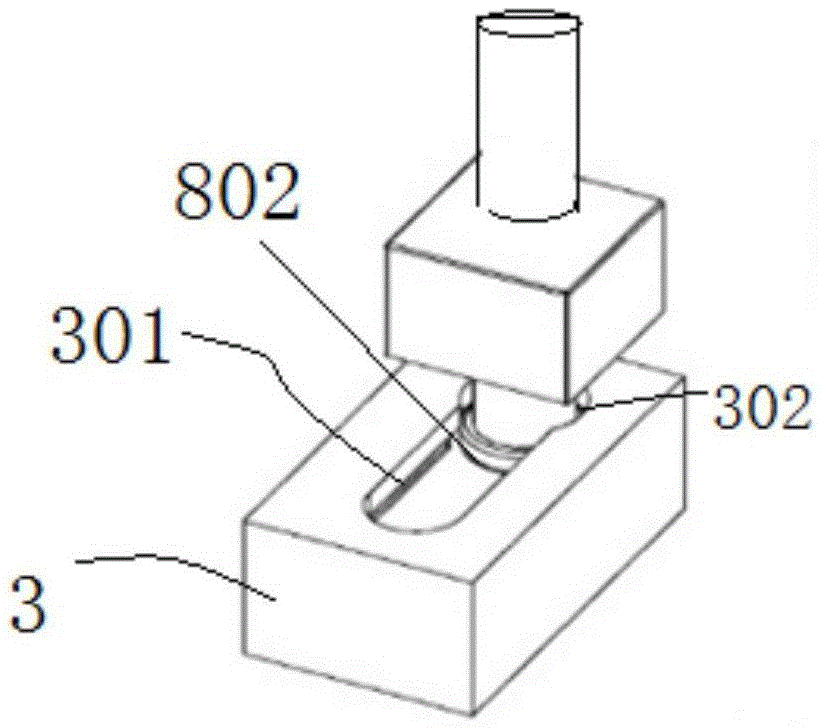

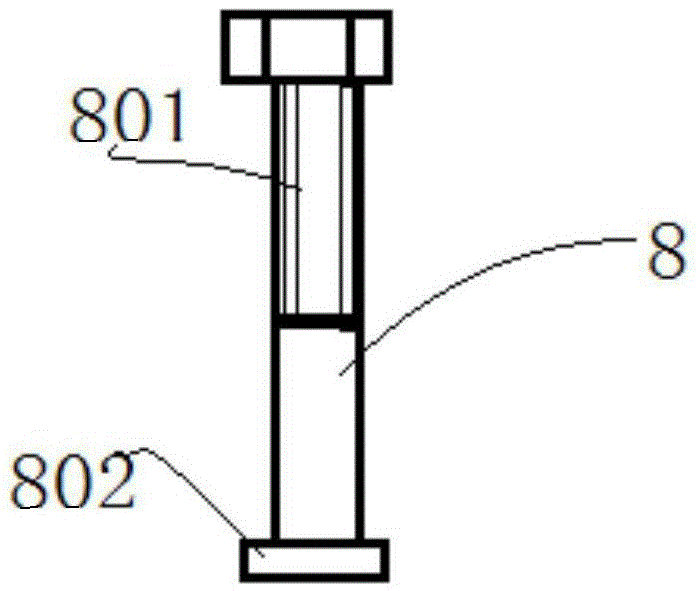

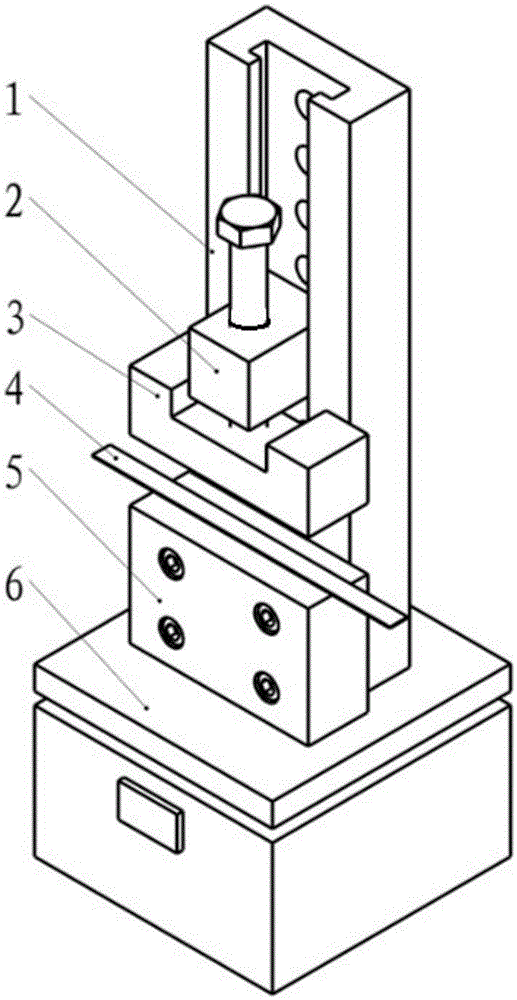

[0019] exist figure 1 Among them, the pressure table is composed of the adjusting guide rail 1, the fixed block 2, the upper pressing block 3 and the lower pressing block 5, which provide the required pressure during the welding process. The material of the pressure table is made of high-strength alloy steel, and the joint surface of the upper pressing block 3 and the lower pressing block 5 is precisely processed, and the parallelism and perpendicularity of the surfaces are less than 5 μm / 100mm. The fixed block 2 is embedded in the adjustment guide rail 1 and can move up and down. There is a row of through holes distributed on the adjustment guide rail 1, and the figure 2 It can be seen that the fixing bolt 7 is connected with the fixing block 2 after passing through any through hole, and is fixed on the adjusting guide rail. image 3 It is a partial enlarged view of the upper pressing block and the fixed block through 8 sets of screw bolts. The upper pressing block 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com