Preparation method of 6-amino-1-hexanol by taking calcium carbonate as catalyst

A calcium carbonate and catalyst technology, which is applied in the field of preparation of 6-amino-1-hexanol, can solve problems such as low yield and unsatisfactory catalytic efficiency, achieve high yield, stable catalytic effect, and widely popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

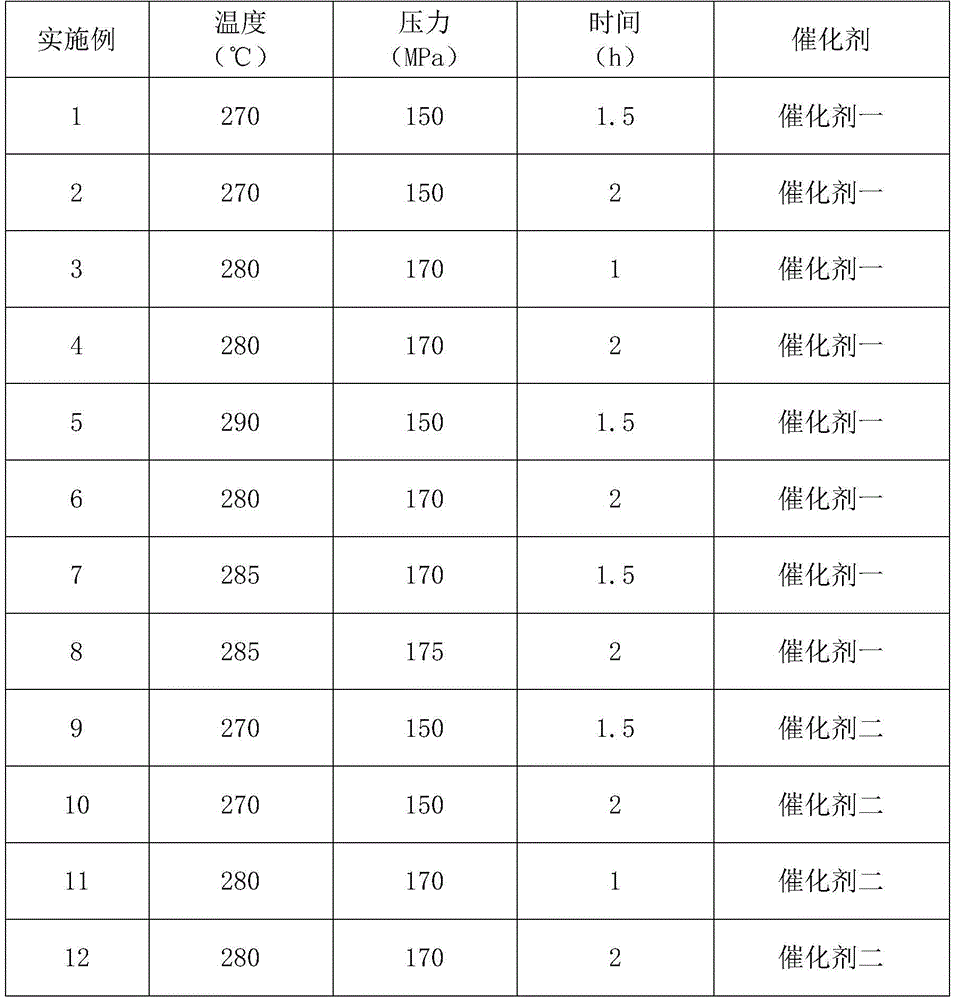

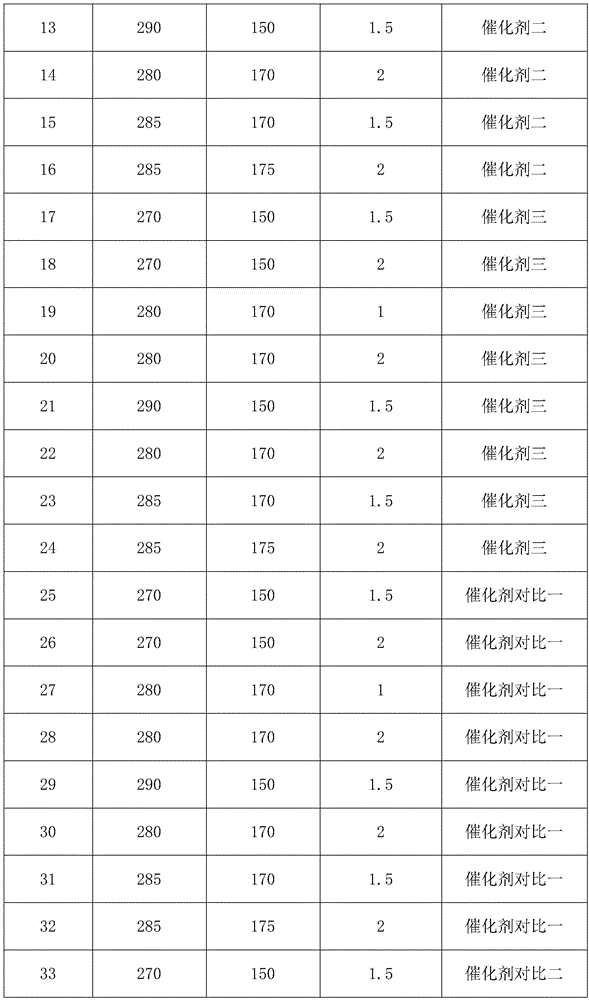

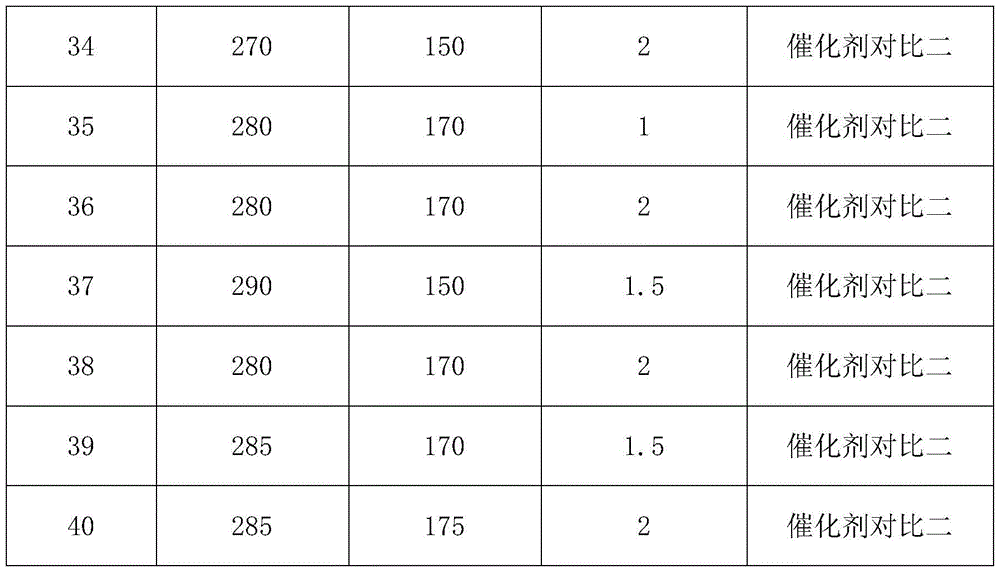

[0029] A preparation method of 6-amino-1-hexanol using calcium carbonate as a catalyst, using calcium carbonate as a reaction catalyst, 1,6-hexanediol, ammonia and hydrogen at a temperature of 270-290 ° C and a pressure of 150 6-amino-1-hexanol is generated by mixing, heating and pressurizing under the condition of -180Mpa for 1.5-2 hours.

[0030] Catalyst 1: Active calcium carbonate, purchased from Huayu Nano Powder Group, with active ingredient content of CaCO3 ≥ 98%, content of Fe2O3 ≤ 0.30%, content of Al2O3 ≤ 0.20%, and content of MgO ≤ 0.16%.

[0031] Catalyst 2: ultra-fine calcium carbonate, purchased from Huayu Nano Powder Group, CaCO3 active ingredient content ≥ 96%, iron content ≤ 0.1%, MgCO3 content ≤ 1.7%, hydrochloric acid insoluble content ≤ 0.2.

[0032] Catalyst 3: ultrafine calcite powder, purchased from Huayu Nano Powder Group, with CaCO3 active ingredient content ≥ 98%, iron content ≤ 0.1%, manganese content ≤ 0.008%.

[0033] Comparative catalyst one: sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com