Method for preparing nanoscale Cu-based metal organic framework material

An organic framework and metal-based technology, which is applied in the field of preparing nano-scale Cu-based metal-organic framework materials using microchannel reactors, can solve the problems of increasing the post-processing cost of organic liquids, reducing raw material utilization efficiency, and unstable product performance. Good prospects for large-scale industrial production, improved reaction efficiency and production efficiency, and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

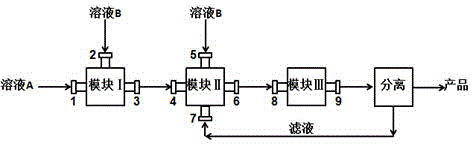

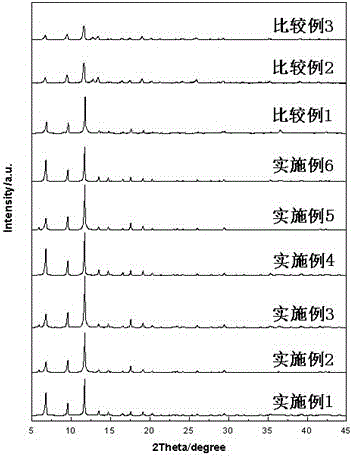

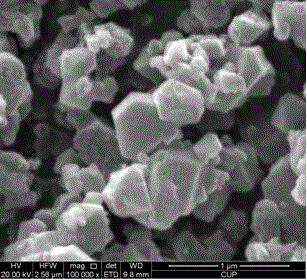

[0037] Dissolve 12.1 g of copper nitrate trihydrate in 500 ml of ethanol to form liquid A, and dissolve 10.5 g of trimellitic acid in 500 ml of ethanol to form liquid B. The flow rate of A liquid is 5μl / min, and it is fed into module I from feed port 1, while the flow rate of B liquid is 5μl / min, and it is injected into module I from feed port 2. The temperature of module I is 40°C and the pressure At 0.1MPa, the A liquid and the B liquid are uniformly mixed in the module I to produce a liquid containing Cu-MOFs seed crystals, and the residence time is 180s. The feed liquid containing Cu-MOFs seed crystals is fed into the microchannel reactor module II from the feed port 4, and the flow rate is 10μl / min. The remaining liquid B is fed into the microchannel reactor from the feed port 5 at a flow rate of 5μl / min In module II, the temperature of module II is 50°C, the pressure is 0.1MPa, and the residence time is 240s. After reacting for a certain period of time, the product liqui...

Embodiment 2

[0039] Dissolve 121 g of copper nitrate trihydrate in 500 ml of ethanol to form liquid A, and dissolve 210 g of trimellitic acid in 500 ml of ethanol to form liquid B. The flow rate of A liquid is 200μl / min, which is fed into module I from the feed port 1, while the flow rate of B liquid is 200μl / min, which is injected into module I from the feed port 2. The temperature of module I is 70°C, and the pressure At 1.0MPa, the A liquid and the B liquid are uniformly mixed in the module I to produce a liquid containing Cu-MOFs seed crystals, and the residence time is 30s. The feed liquid containing Cu-MOFs seed crystals is sent to module II from the feed port 4, and the flow rate is 400μl / min. The remaining B liquid is sent to the module II from the feed port 5 at a flow rate of 200μl / min. -The initial crystallization reaction of MOFs material, where the temperature of module II is 100°C, the pressure is 1.0MPa, and the residence time is 60s. After reacting for a certain period of t...

Embodiment 3

[0041] 60.5 g of copper nitrate trihydrate was dissolved in 500 ml of ethanol to form liquid A, and 105 g of trimellitic acid was dissolved in 500 ml of ethanol to form liquid B. The flow rate of A liquid is 100μl / min, and it is fed into module I from the feed port 1, while the flow rate of B liquid is 100μl / min, and it is injected into the module I from the feed port 2. The temperature of module I is 60℃ and the pressure At 0.5MPa, the A liquid and the B liquid are uniformly mixed in the module I to generate a liquid containing Cu-MOFs seed crystals, and the residence time is 60s. The feed liquid containing Cu-MOFs seed crystals is fed into module II from the feed port 4 with a flow rate of 100μl / min. The remaining liquid B is fed into module II from the feed port 5 at a flow rate of 100μl / min, and Cu is generated. -The initial crystallization reaction of MOFs material, where the temperature of module II is 60°C, the pressure is 0.5MPa, and the residence time is 120s. After a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com