Liquor Brewing Automation System and Liquor Brewing Technology

An automated system and liquor technology, applied in the field of winemaking, can solve problems such as large wine damage, high labor intensity for operators, and unfavorable environmental sanitation management, and achieve the effects of reducing the impact of product quality, realizing mechanized automation, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

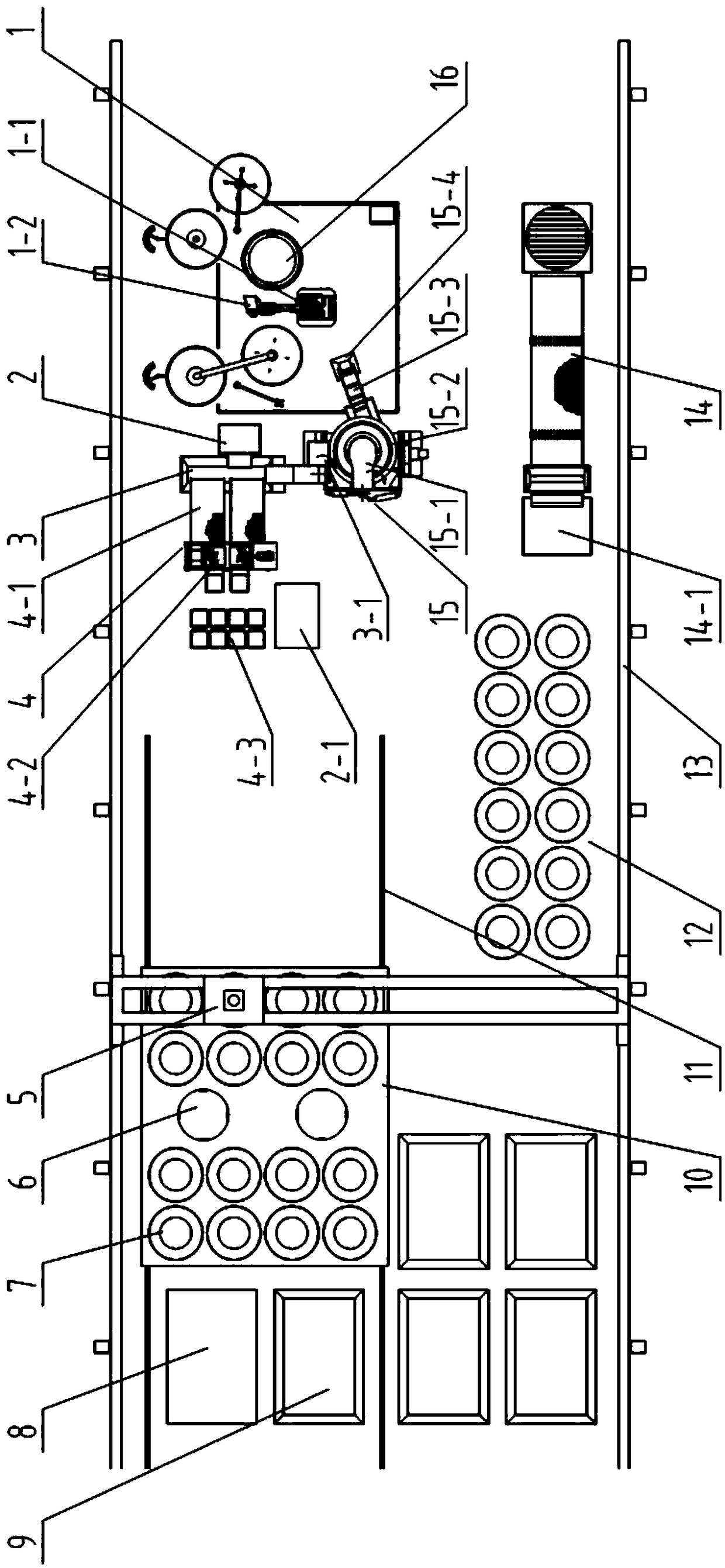

[0019] The present invention will be further described below in conjunction with the drawings.

[0020] Such as figure 1 As shown, the specific operation steps of the liquor brewing automation system of the present invention are as follows: 1) Use the first manipulator 5 to take out the fermented grains from the pit 8 according to the process requirements, and put them into the fermented barrel 7, and add the lid after filling. 6 Preservation, the number of lagoons 7 meets the technological requirements of layered and uniform storage of lagoons. In order to pick up and put lagoons nearby, the lagoon device 10 can carry the lagoons 7 to the vicinity of the pit 8. The function of the lagoon storage area 12 is Realize the logistics buffer and turnover of the glutinous rice container; 2) Send the glutinous rice in the glutinous pot 7 to the mixing unit 15, and open the bottom cover of the glutinous container 7 to drop the glutinous into the mixing machine 15-2 of the mixing unit 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com