Composite foundation and construction method thereof

A construction method and technology of composite foundation, which are applied in the directions of foundation structure engineering, soil protection, sheet pile wall, etc. Density, avoid uneven settlement, reduce the effect of settlement value deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by specific examples.

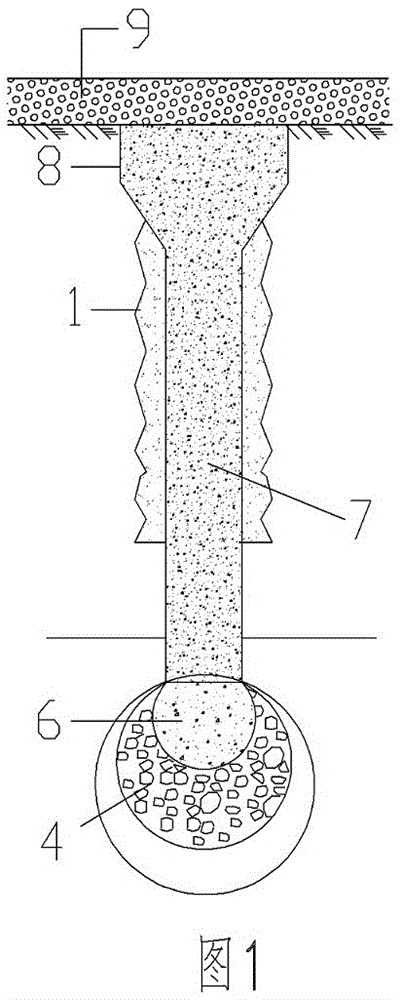

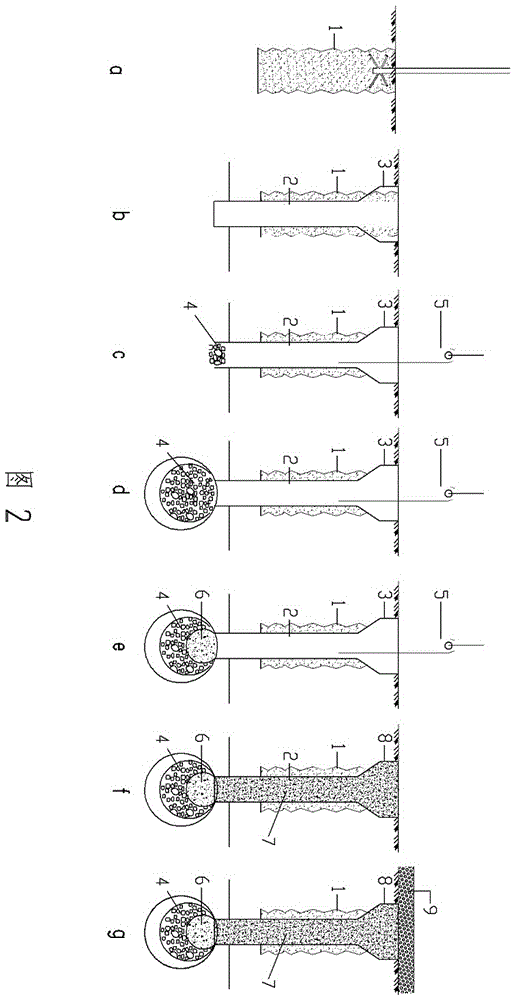

[0021] figure 1 It is a schematic composition diagram of an embodiment of the composite foundation of the present invention, such as figure 1 As shown, the composite foundation includes a pile foundation and its upper cushion layer 8, and the pile foundation is composed of a cement-soil pile body 1 on the periphery, a concrete pile body 7 inside the cement-soil pile body 1, and a pile top diameter expansion part on the top of the concrete pile body 7. 8, and the lower end of the concrete pile body 6 is composed of four parts: the pile end carrier part composed of the tamped reinforcing material 4 and dry hard concrete 5; wherein the diameter of the cement soil pile body 1 on the periphery is 600mm, the length is 6000m, and the concrete pile body 7 The diameter is 400mm, the length is 8000mm, and the volume of the tamped reinforcing material 4 is 0.8m 3 , the volume of tamped dry hard concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com