Plume neutralizer of space electric thruster

A thruster and space electric technology, applied in the aerospace field, can solve the problems of high equivalent potential of electron current, unsuitable electron source for space electric propulsion system, and contamination of emitter material, so as to improve system efficiency and reliability, avoid Harmful effects, propellant saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

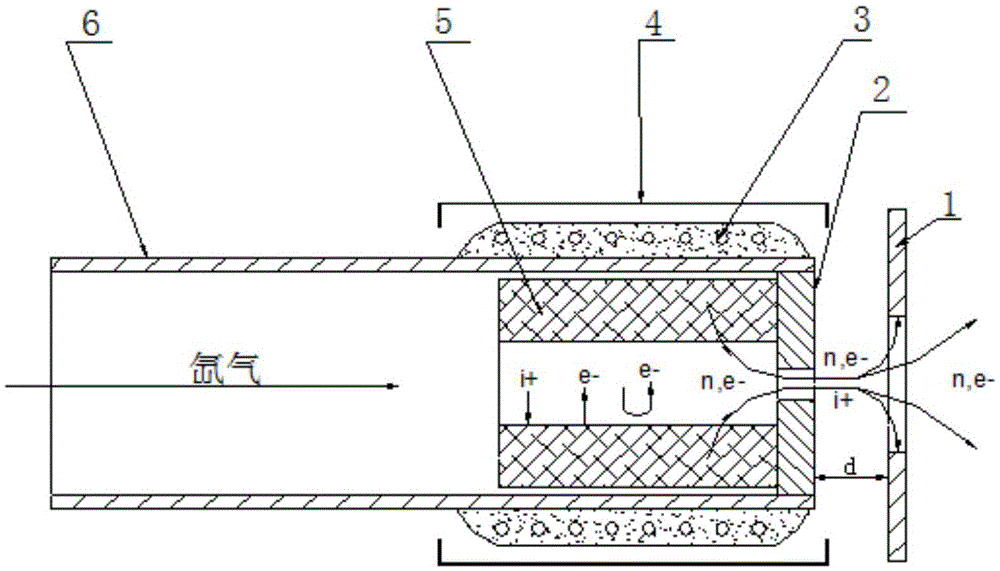

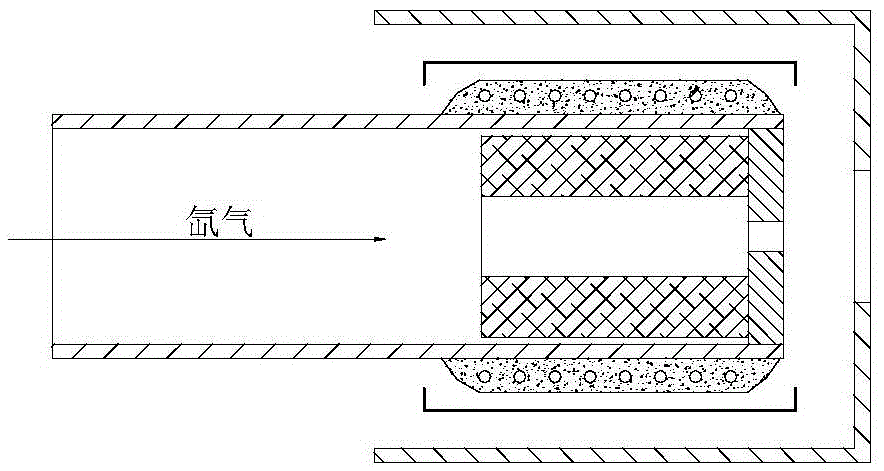

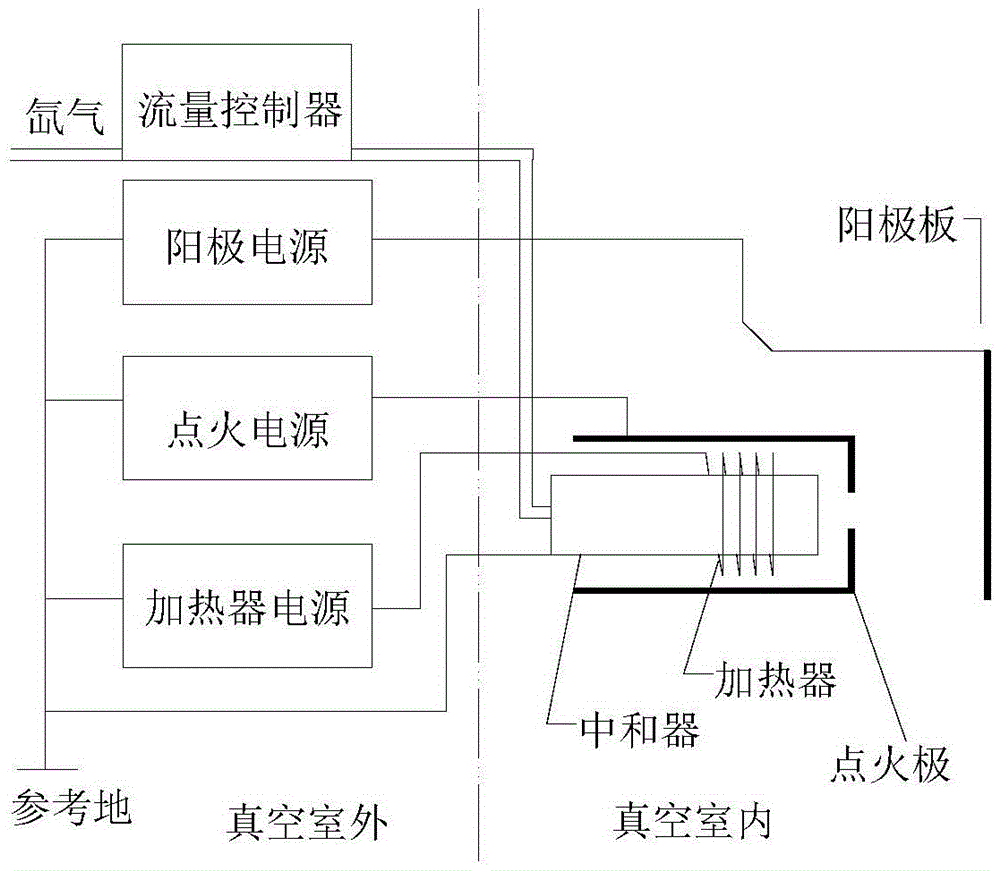

[0022] Such as figure 1 As shown, the neutralizer includes an ignition electrode 1, a top orifice plate 2, a heater 3, a heat shielding cylinder 4, an emitter 5 and a support tube 6, the emitter 5 is installed inside the support tube 6, and the top orifice plate 2 blocks The outside of the emitter 5 is fixedly connected with the support tube 6, the heater 3 is installed on the outside of the support tube 6 at a position corresponding to the emitter 5, the heating zone covers the entire emitter 5, and the heater 3 is wrapped with an insulating ceramic layer; The shielding tube 4 is covered outside the heater 3, and there is a gap between the heater 3 and its insulating ceramic layer to reduce heat conduction and improve radiation protection efficiency. There is a gap between the small holes of the orifice plate 2, the central hole of the ignition electrode 1 is coaxial with the small hole of the top hole plate, the emitter material of the neutralizer is a barium tungsten emitte...

Embodiment 2

[0025] Such as figure 1 As shown, the neutralizer includes an ignition electrode 1, a top orifice plate 2, a heater 3, a heat shielding cylinder 4, an emitter 5 and a support tube 6, the emitter 5 is installed inside the support tube 6, and the top orifice plate 2 blocks The outside of the emitter 5 is fixedly connected with the support tube 6, the heater 3 is installed on the outside of the support tube 6 at a position corresponding to the emitter 5, the heating zone covers the entire emitter 5, and the heater 3 is wrapped with an insulating ceramic layer; The shielding tube 4 is covered outside the heater 3, and there is a gap between the heater 3 and its insulating ceramic layer to reduce heat conduction and improve radiation protection efficiency. A gap is provided between the small holes of the orifice plate 2, and the central hole of the ignition pole 1 is coaxial with the small hole of the top hole plate. The emitter material of the hollow cathode is made of oxide emit...

Embodiment 3

[0028] Such as figure 1 As shown, the neutralizer includes an ignition electrode 1, a top orifice plate 2, a heater 3, a heat shielding cylinder 4, an emitter 5 and a support tube 6, the emitter 5 is installed inside the support tube 6, and the top orifice plate 2 blocks The outside of the emitter 5 is fixedly connected with the support tube 6, the heater 3 is installed on the outside of the support tube 6 at a position corresponding to the emitter 5, the heating zone covers the entire emitter 5, and the heater 3 is wrapped with an insulating ceramic layer; The shielding tube 4 is covered outside the heater 3, and there is a gap between the heater 3 and its insulating ceramic layer to reduce heat conduction and improve radiation protection efficiency. A gap is provided between the small holes of the orifice plate 2, and the central hole of the ignition pole 1 is coaxial with the small hole of the top hole plate. The emitter material of the neutralizer is lanthanum hexaboride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com