Quantum dot and plasma coupled color filter preparation method

A color filter and plasma technology, applied in the direction of optical filters, optics, instruments, etc., can solve the problems of light-emitting wavelength red shift, energy loss, etc., achieve large absorption cross-section, reduce energy loss, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

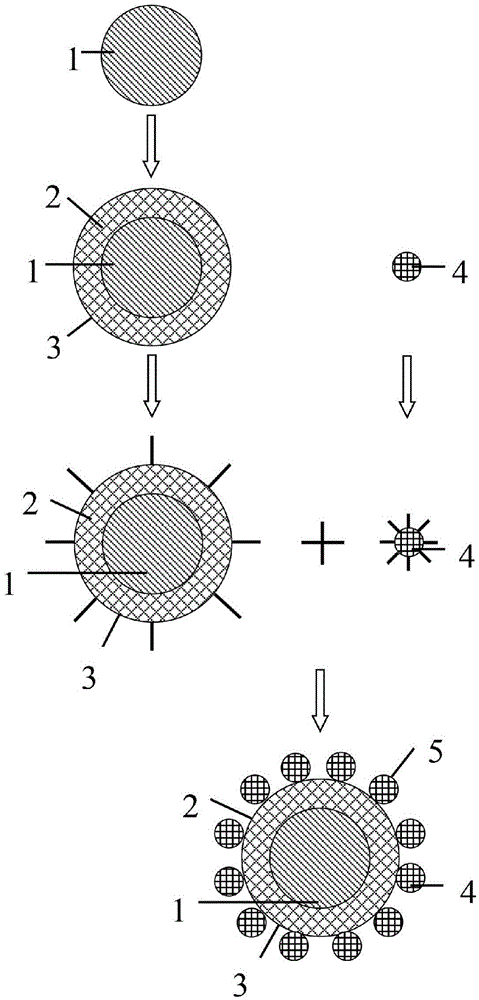

[0022] The preparation method of the metal quantum dot plasma coupler color filter is as follows:

[0023] 1) Preparing metal nanoparticles 1 by polyol method;

[0024] 2) Using ammonia water to catalyze the hydrolysis of ethyl orthosilicate to prepare metal / SiO coated with different thicknesses of silica shells 2 2 core / shell composite particle 3;

[0025] 3) Amination of metal / SiO using 3-aminopropyltriethoxysilane 2 the surface of the core / shell composite particle 3;

[0026] 4) Prepare oil-phase red light quantum dots and green light quantum dots 4 by high-temperature pyrolysis, and replace their 4 surface ligands with 3-mercaptopropionic acid;

[0027] 5) Using the self-assembly method to combine metal / SiO 2 The core / shell composite particle 3 is connected with the quantum dot 4 to form a metal quantum dot plasmonic coupler 5;

[0028] 6) Preparation of SiO by using ammonia water to catalyze the hydrolysis of ethyl orthosilicate 2 Sol;

[0029] 7) Combining metal q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com