Hundred nanometer scale ultrafine light needle field focusing

A nanoscale, design method technology, applied in optics, optical components, instruments, etc., can solve the problem that the focused light needle field is on the side of the incident light field, and relies on ultra-precision aspheric processing technology, radial polarization vector beam generation Due to the complex system and high cost of high-end apochromatic microscope objectives, the effect of flexible design method, light structure and low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

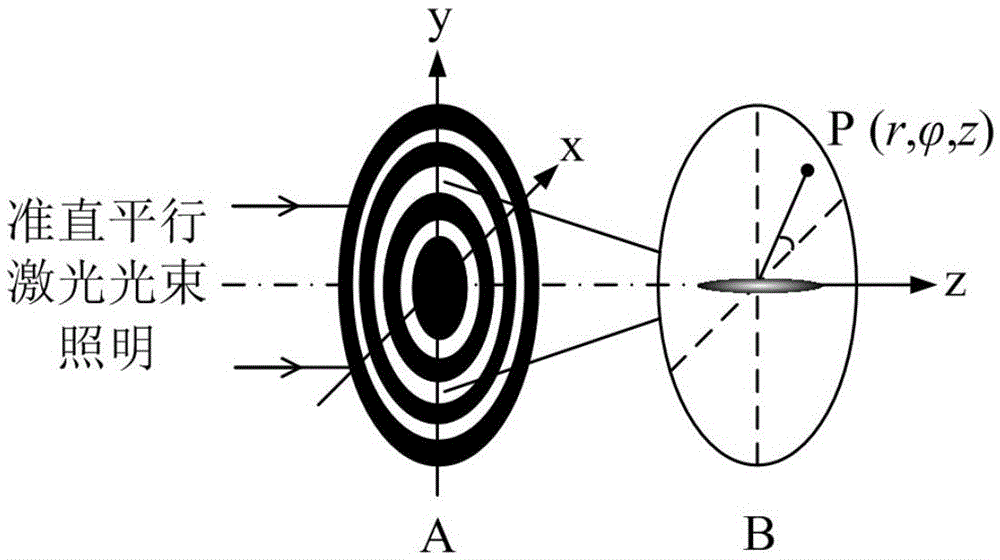

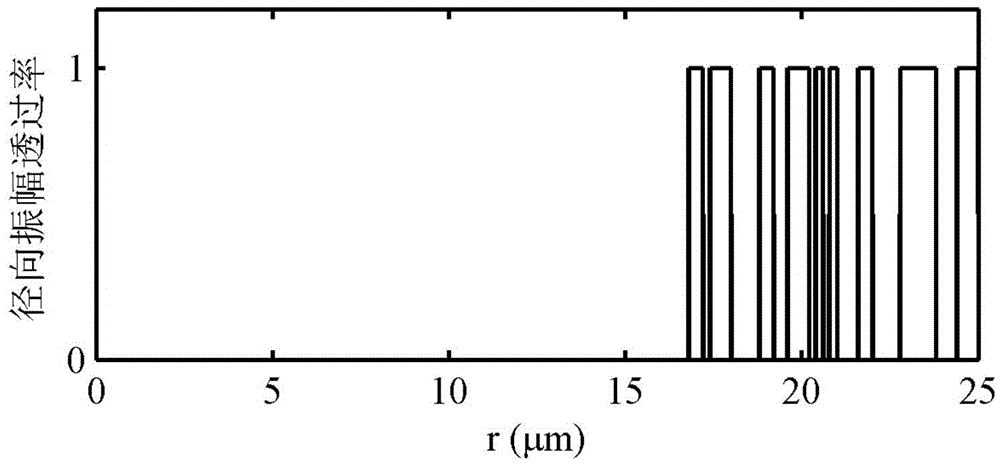

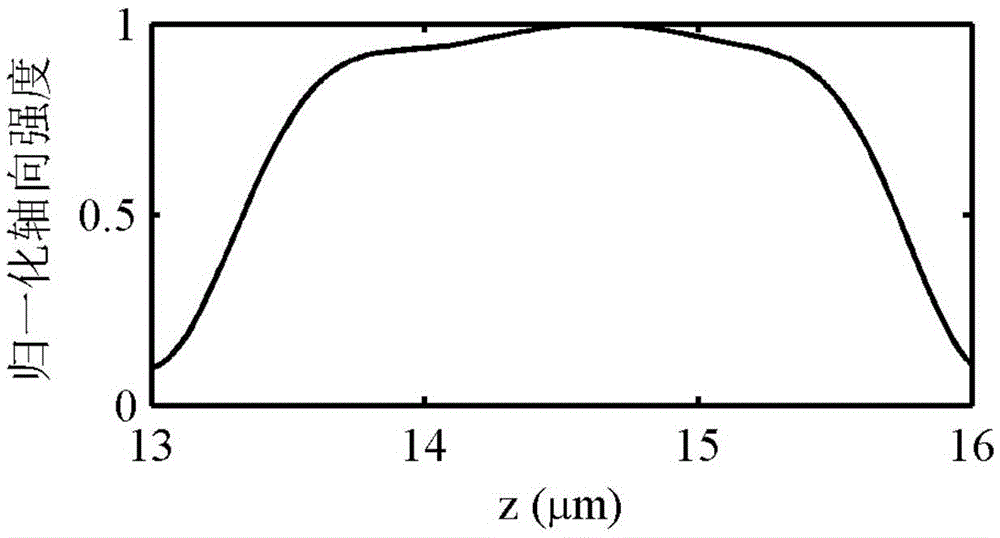

[0022] Such as figure 1 As shown, the short-wavelength ultraviolet laser beam is directly focused by using a microstructured metal film ring plate, and modulated at a distance of tens of microns from the back surface of the ring plate to generate a nanoscale ultra-fine light needle field distribution, which is carried out using Vectorial Angular Spectrum Theory. Light Field Propagation Analysis.

[0023] (1) Integral representation of light field in vector angle spectrum theory

[0024] Assume that linearly polarized light (LPB) vibrating along the X axis propagates forward along the Z axis, such as figure 1 As shown, after diffraction by the microstructured metal film ring plate, at any point in the z>0 vertical axis plane The right-angle component of the electric field E at the position is derived from the vector angle spectrum theory

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com