Water-dispersed insulating varnish composition, insulating coil using same, and method for producing hermetic electric compressor, insulating coil, and hermetic electric compressor

A technology of electric compressors and insulating varnishes, applied in the manufacture of motor generators, insulators, electric components, etc., can solve the problems of organic components volatilization, volatilization, air pollution, etc., and achieve the effect of less VOC generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

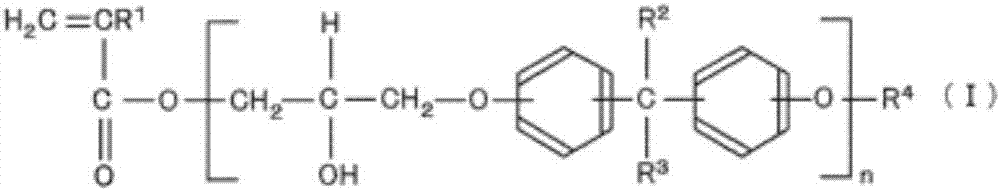

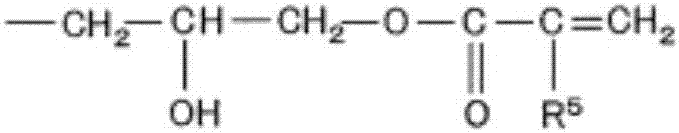

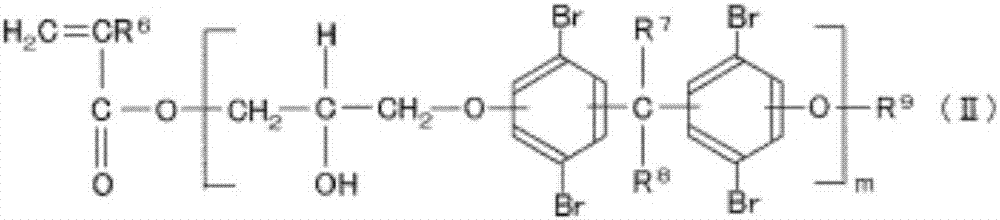

[0021] The water-dispersible insulating varnish composition according to Embodiment 1 of the present invention is characterized in that a thermosetting resin having two or more (meth)acryloyl groups in one molecule has a low solubility in water and is within the above-mentioned The surface of a polyfunctional vinyl monomer having two or more (meth)acryloyl groups or allyl groups in one molecule dissolved in a thermosetting resin, an organic peroxide as a reaction initiator, and a dispersant Active agent, mixed with water, free of monofunctional vinyl monomers with one reactive group.

[0022] In the water-dispersed insulating varnish composition of the present invention, since the organic component with low solubility in water is uniformly dispersed in nanometer size in water, the emulsified particles do not settle even in a standing state, and the dispersion stability excellent. In addition, the cured product obtained by heat-treating the water-dispersed insulating varnish c...

Embodiment

[0071] Hereinafter, although an Example and a comparative example demonstrate the detail of this invention, this invention is not limited to these.

[0072]

[0073] The water-dispersible insulating varnish composition of Example 1 was prepared by phase inversion emulsification method. Specifically, 80 wt. parts, 20 parts by weight of trimethylolpropane trimethacrylate as polyfunctional vinyl monomer, 1 part by weight of dicumyl peroxide as organic peroxide, and as surfactant, H.L.B is 16 parts by weight of polyoxyethylene polycyclic phenyl ether were mixed and stirred uniformly to prepare an organic solution that became an oil phase. When 120 parts by weight of water were prepared, and the organic solution was dripped with stirring, it became a viscous suspension. This state is the phase inversion point where the continuous phase changes from the oil phase to the water phase. The dripping of water was stopped at this phase inversion point, and it stirred for 5 minutes. ...

Embodiment 2

[0100] The water-dispersible insulating varnish composition of Example 2 was prepared by a phase inversion emulsification method. Specifically, 75 wt. 10 parts by weight of trimethylolpropane triacrylate and 15 parts by weight of diethylene glycol dimethacrylate as polyfunctional vinyl monomer, 2.5 parts by weight of tert-butyl peroxybenzoate as organic peroxide 15 parts by weight of polyoxyethylene polycyclic phenyl ether as a surfactant, H.L.B is 19, and mixed uniformly to prepare an organic solution that becomes an oil phase. When 130 parts by weight of water were prepared, and the organic solution was dripped with stirring, it became a viscous suspension. This state is the phase inversion point where the continuous phase changes from the oil phase to the water phase. The dripping of water was stopped at this phase inversion point, and it stirred for 10 minutes. Then, the remaining water was slowly added while stirring, and after adding the entire amount of water, the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com