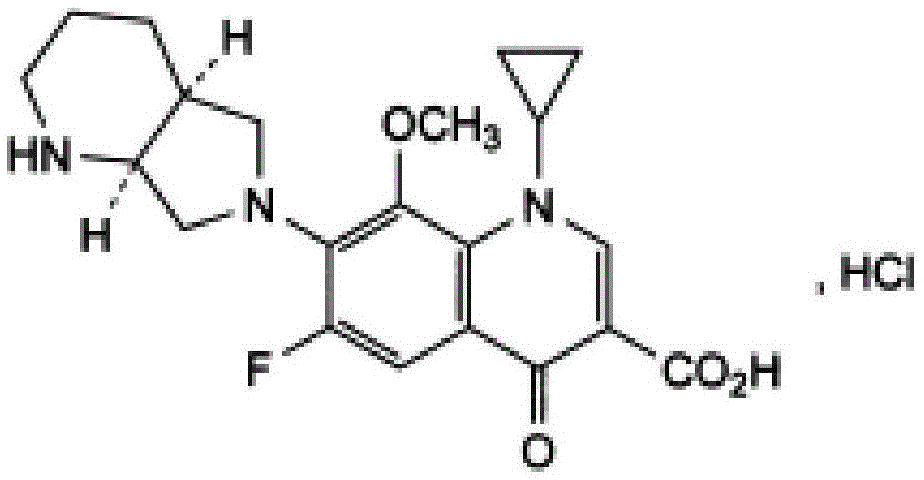

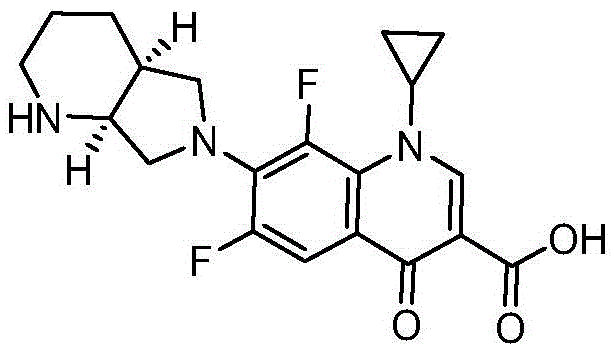

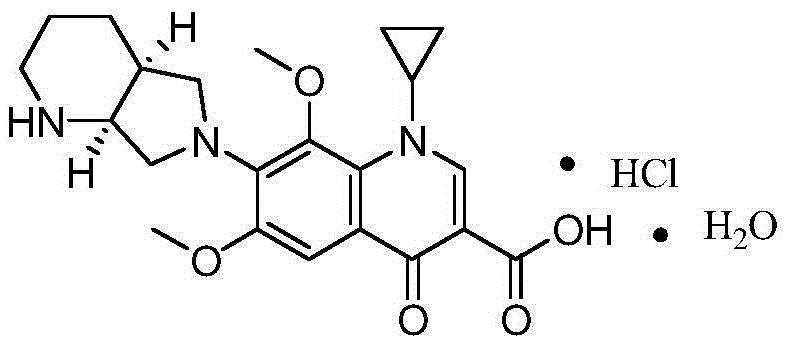

Preparation process of moxifloxacin hydrochloride sodium chloride injection

A technology of moxifloxacin hydrochloride and sodium chloride injection, applied in the new moxifloxacin hydrochloride and sodium chloride injection and the field of preparation thereof, can solve the problems of low sterility assurance level, poor operability, inconvenient use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] prescription:

[0119] Raw materials

content

40g

Sodium chloride

200g

Appropriate amount

Appropriate amount

Appropriate amount

Water for Injection

Set volume to 25000ml

pH value

4.1-4.6

Co-made

100 sticks

[0120] Preparation Process:

[0121] 1. Weighing: Weigh moxifloxacin hydrochloride and sodium chloride respectively according to the prescription amount, and prepare 1mol / L sodium hydroxide solution and 1mol / L hydrochloric acid solution for later use;

[0122] 2. Dosing (1): Take 10% of the full amount of water for injection in the prescription, add the prescribed amount of moxifloxacin hydrochloride, stir to dissolve completely, add medicinal charcoal with a current liquid amount of 0.05% (w / w), and stir well , stirred and adsorbed for 15 minutes, decarbonized and filtered with a 0.45 μm filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com