Method and device for treating xylene-containing waste gas

A treatment method and a treatment device technology, which are applied in the direction of gas treatment, combined devices, separation methods, etc., can solve the problems of reducing the removal effect of biological filtration devices, corrosion, and wear and tear of the device body, so as to avoid secondary pollution by-products, The effect of reasonable process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

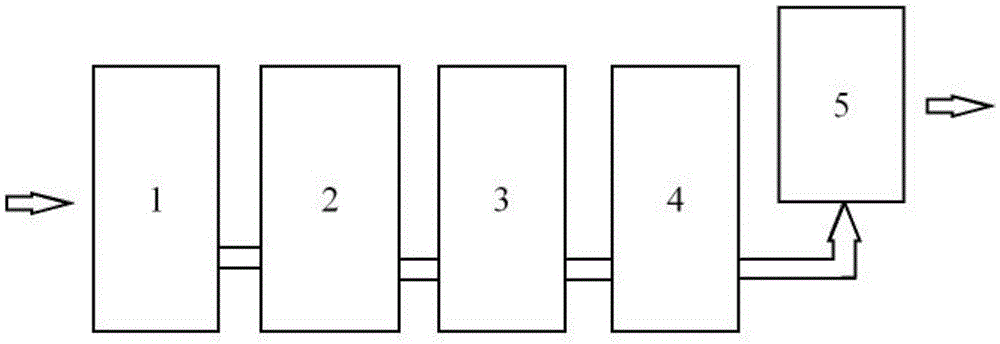

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Compared with the prior art, the present invention proposes a treatment method containing xylene waste gas, which is characterized in that it comprises the following steps:

[0022] Step 1: Send the organic waste gas into the dust removal room for dust removal treatment;

[0023] Step 2: Send the dust-removed exhaust gas into the cooling room for cooling treatment, so that the gas temperature drops to 25-35 degrees Celsius;

[0024] Step 3: Send the waste gas after the cooling treatment to the spray tower, and spray it with dimethylformamide at 10-15°C;

[0025] Step 4: The sprayed gas passes through the electric demister;

[0026] Step 5: The gas treated by electrostatic demisting is further subjected to microbial degradation treatment after being adsorbed by glass fibers and activated carbon particles.

[0027] The electric demister of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com