Preparation method and application of crosslinking-enzymolysis composite superfine modified starch adsorbent

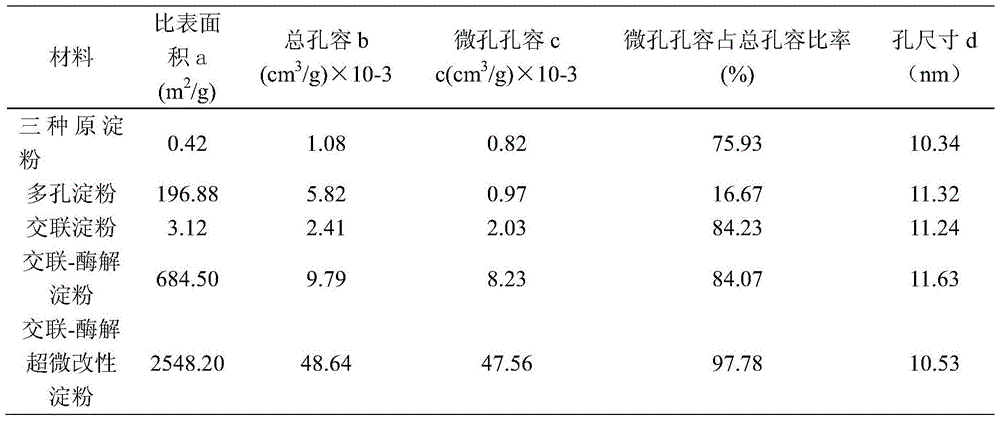

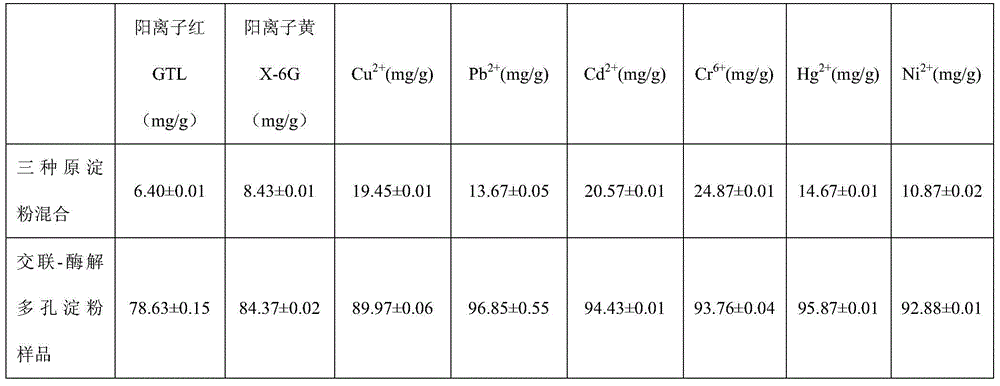

An adsorbent and starch technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of small pore volume, shallow pore depth, easy damage, etc., and increase the specific surface area. and pore volume, the preparation process is simple, and the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preparation method of a cross-linking-enzymolysis composite ultrafine modified starch adsorbent, comprising the following steps:

[0028] (1) Dry three kinds of starches of corn, sweet potato and potato until the water content is less than 1%, and then carry out superfine pulverization respectively with a superfine pulverizer, the speed of the runner is 3500r / min, the speed of the cyclone separator is 3000r / min, and the pulverization time is 5h, the particle diameter is 10-50 μm superfine starch; then three kinds of superfine starches of corn, sweet potato and potato are mixed evenly with the ratio of mass ratio 1:4:3, then added into water and stirred to obtain starch emulsion; the total mass of starch and The mass ratio of water is preferably 40:60.

[0029] (2) Use sodium hydroxide solution with a mass concentration of 3% to adjust the pH of the starch emulsion to 7.5-8.5, then add sodium tripolyphosphate solution, mix well, and cross-link at 75°C-80°C for 1-1.5h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com