Y2O3/Cr2O3 composite gradient anti-hydrogen coating layer and preparation method thereof

A composite coating, cr2o3 technology, applied in the direction of chemical instruments and methods, lamination, lamination equipment, etc., can solve the problems of separation of the coating from the substrate, affecting the hydrogen resistance performance of the coating, etc., and achieve thickness controllability and compactness High, excellent effect of hydrogen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

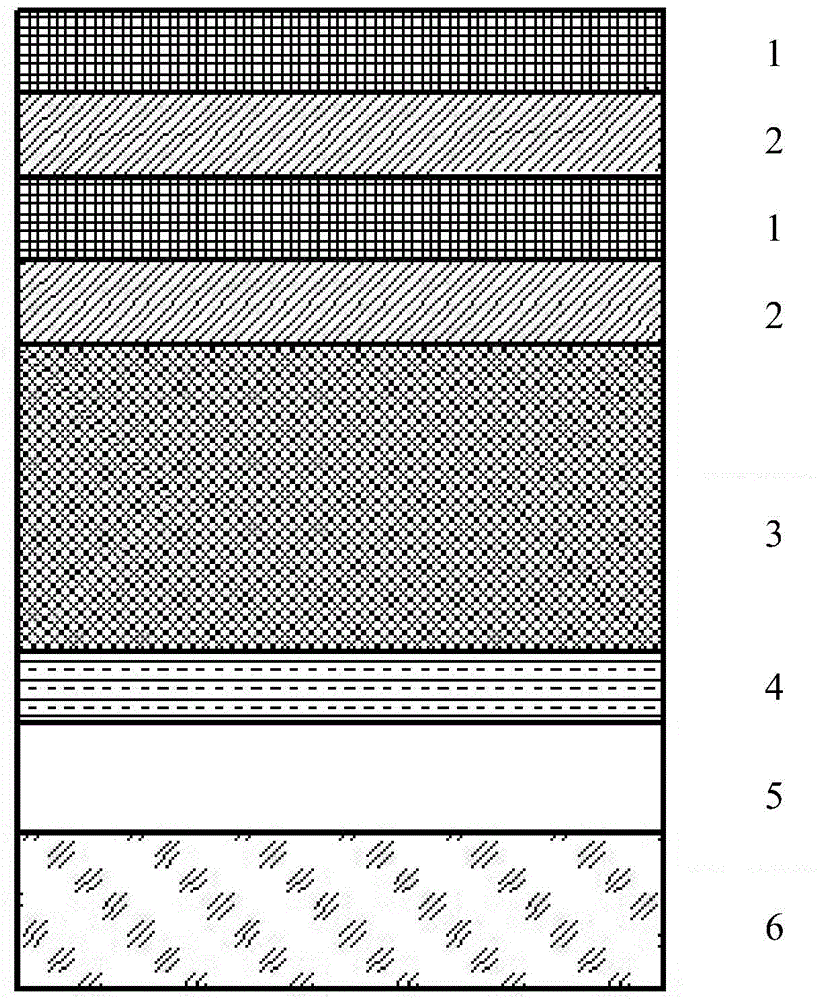

Image

Examples

Embodiment 1

[0030] Y for the preparation of high-temperature vacuum heat collector tubes with a thickness of 0.5 μm 2 o 3 / Cr 2 o 3Composite gradient hydrogen barrier coating:

[0031] (1) Polish the inner surface of the stainless steel tube to a roughness of 1 μm;

[0032] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; specific process parameters are: reaction source temperature 150°C; reaction time 30min; carrier gas flow rate 200ml / min.

[0033] (3) Using metal-organic chemical vapor deposition technology to prepare Y on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; the specific process parameters are: reaction source temperature 100°C; reaction time 30min; carrier gas flow rate 100ml / min.

[0034] (4) Repeat the above step (2);

[0035] (5) Repeat the above step (3).

[0036] Finally, a multilayer Y with a thickness of about 0.5 μ...

Embodiment 2

[0039] Y for the preparation of high temperature vacuum heat collecting tubes with a thickness of 1 μm 2 o 3 / Cr 2 o 3 Composite gradient hydrogen barrier coating:

[0040] (1) Polish the inner surface of the stainless steel tube to a roughness of 0.5 μm;

[0041] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; specific process parameters are: reaction source temperature 180°C; reaction time 60min; carrier gas flow rate 200ml / min.

[0042] (3) Using metal-organic chemical vapor deposition technology to prepare Y on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; specific process parameters are: reaction source temperature 120°C; reaction time 60min; carrier gas flow rate 150ml / min.

[0043] (4) Repeat the above step (2);

[0044] (5) Repeat the above step (3).

[0045] Finally, a multilayer Y with a thickness of about 1 μm is...

Embodiment 3

[0048] Y 2 o 3 / Cr 2 o 3 Composite gradient hydrogen barrier coating:

[0049] (1) Polish the inner surface of the stainless steel tube to a roughness of 0.3 μm;

[0050] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; specific process parameters are: reaction source temperature 200°C; reaction time 45min; carrier gas flow rate 200ml / min.

[0051] (3) Using metal-organic chemical vapor deposition technology to prepare Y on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 Coating; specific process parameters are: reaction source temperature 160°C; reaction time 45min; carrier gas flow rate 80ml / min.

[0052] (4) Repeat the above step (2);

[0053] (5) Repeat the above step (3).

[0054] Finally, a multilayer Y with a thickness of about 0.8 μm was obtained 2 o 3 and Cr 2 o 3 Composite gradient hydrogen barrier coating.

[0055] Dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com