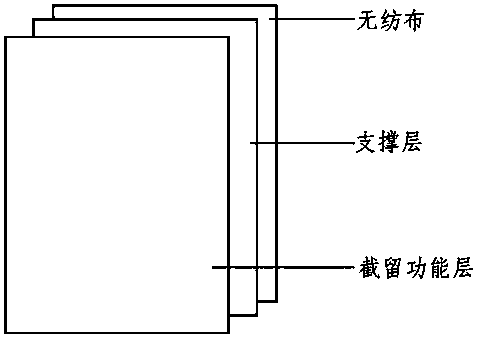

Multilayer Composite Nanofiber Membrane and Its Application

A nanofiber membrane and multi-layer composite technology, which is applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of low mechanical strength and high filtration resistance of electrospun nanofiber membranes, and achieve resistance Small size, high filtration efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

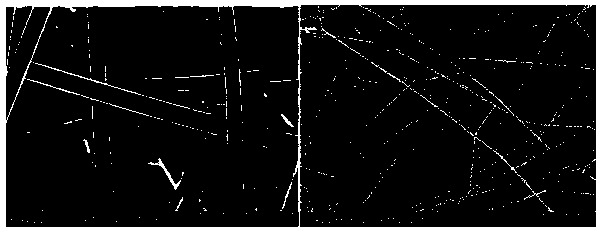

[0028] A PET support layer with a filament diameter of 10 microns and a weight per unit area of 80 g / m was prepared by meltblowing 2 , with a thickness of 200 microns, using electrospinning technology to prepare a PET interception layer with a diameter of 300 nanometers of filaments on the surface of the PET thick fiber membrane, and a thickness of 100 microns. They are respectively used in the fields of air filtration, membrane distillation desalination and oil-water separation.

[0029] (1) The composite fiber membrane is used for air filtration, and the removal efficiency of PM 2.5 is 100%.

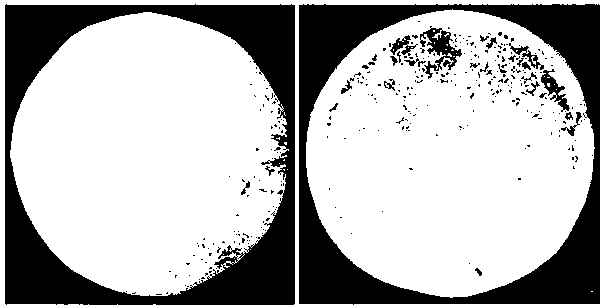

[0030] (2) After the composite fiber membrane is hot-pressed, the contact angle of the intercepting layer to water reaches 140°, which is used for membrane distillation feed liquid for desalination and desalination of seawater. When the temperature difference between the two sides is 50 degrees, the water flux is 30LMH, and the cut-off The salt rate is 99.9%. The composite membrane...

Embodiment 4-6

[0033] Prepare a PP support layer with a fiber diameter of 5 microns by melt blowing, and a weight per unit area of 100 g / m 2 , with a thickness of 150 microns, using electrospinning technology to prepare a PVDF nanofiber trapping layer with a diameter of 100 nanometers and a thickness of 50 microns on the surface of PP fibers.

[0034] (1) The composite fiber membrane is used for air filtration, and the removal efficiency of PM 2.5 is 100%.

[0035] (2) One minute after the composite fiber membrane is hot-pressed at 130 degrees, the contact angle of the PVDF interception layer to water reaches 135 degrees, which is used for desalination and desalination of seawater by membrane distillation feed liquid. When the temperature difference between the two sides is 30 degrees, the water flow The amount is 50LMH, and the salt cut-off rate is 99.8%.

[0036] (3) The obtained composite fiber membrane has a contact angle of 155° to water and 0° to oil, and has special wettability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com