A preparation method of carbon aerogel with broad-spectrum anti-reflection structure

A carbon airgel and anti-reflection technology, which is applied in the preparation/purification of carbon, etc., can solve the problems of high precision preparation of carbon nanotube arrays, limited sample size, poor processability, etc., and achieve excellent broad-spectrum anti-reflection absorption characteristics, easy to control, light weight, wide spectrum, anti-reflection and light-absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

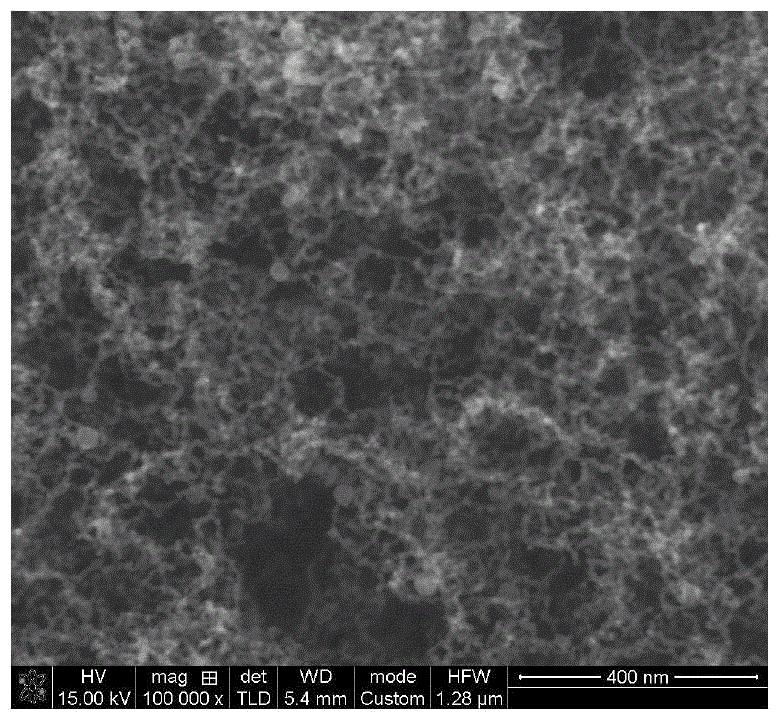

Embodiment 1

[0036]Step 1. Dissolve 0.647g resorcinol in 50mL deionized water, stir until the solution is clear, add 0.871mL formaldehyde solution, stir for 20min, then add 0.147mL sodium carbonate solution, stir for 20min, then add 20mL deionized water, Obtain reaction solution, under stirring condition, add 30mL modified chitosan copper complex solution dropwise in reaction solution, continue to stir 30min, obtain mixed solution; The density 1.066g / mL of described formaldehyde solution, formaldehyde mass percent is 38%; The amount concentration of the substance of described sodium carbonate solution is 0.2mol / L;

[0037] Step 2, sealing the mixed solution, and placing it in an incubator at 80°C for 30 days to obtain a wet gel;

[0038] Step 3, placing the obtained wet gel in a trifluoroacetic acid (3vol.%) / acetone (97vol.%) solution for acidification and aging for 7 days;

[0039] Step 4, place the wet gel after the acidification and aging treatment in a container with fresh acetone for...

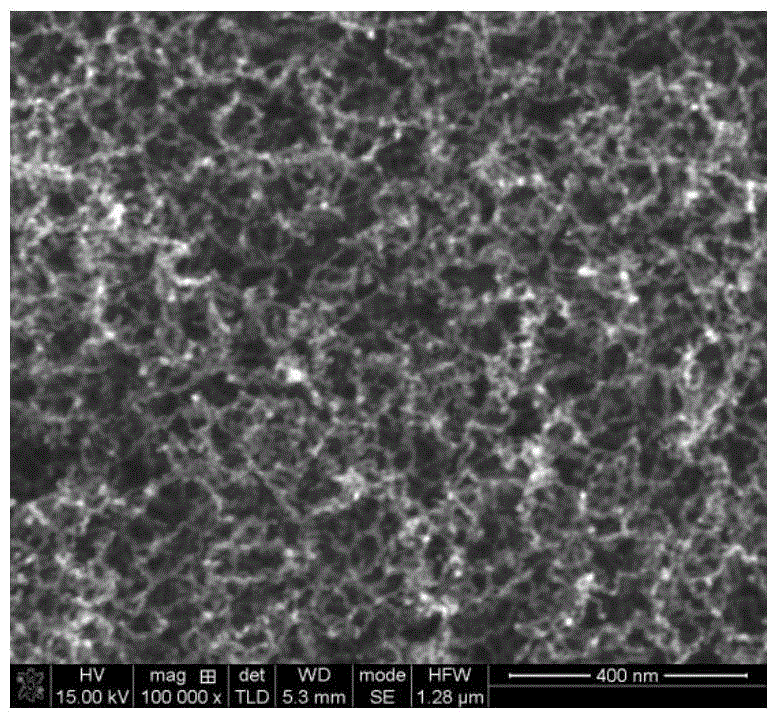

Embodiment 2

[0044] Step 1. Dissolve 1.941g resorcinol in 50mL deionized water, stir until the solution is clear, add 2.614mL formaldehyde solution, stir for 20min, then add 0.441mL sodium carbonate solution, stir for 20min, then add 20mL deionized water, Obtain reaction solution, under stirring condition, add 30mL modified chitosan copper complex solution dropwise in reaction solution, continue to stir 30min, obtain mixed solution; The density 1.066g / mL of described formaldehyde solution, formaldehyde mass percent is 38%; The molar concentration of the substance of the sodium carbonate solution is 0.2mol / L; The preparation method of the modified chitosan copper complex solution adopts the method described in Example 1;

[0045] Step 2, sealing the mixed solution, and placing it in an incubator at 80°C for 30 days to obtain a wet gel;

[0046] Step 3, placing the obtained wet gel in a trifluoroacetic acid (3vol.%) / acetone (97vol.%) solution for acidification and aging for 7 days;

[0047]...

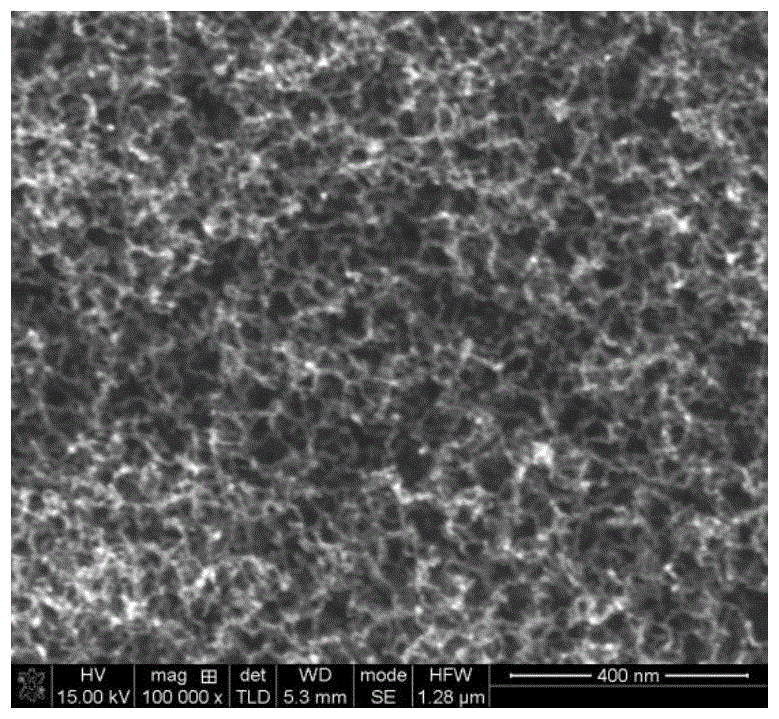

Embodiment 3

[0051] Step 1. Dissolve 2.588g resorcinol in 50mL deionized water, stir until the solution is clear, add 3.485mL formaldehyde solution, stir for 20min, then add 0.588mL sodium carbonate solution, stir for 20min, then add 20mL deionized water, Obtain reaction solution, under stirring condition, add 30mL modified chitosan copper complex solution dropwise in reaction solution, continue to stir 30min, obtain mixed solution; The density 1.066g / mL of described formaldehyde solution, formaldehyde mass percent is 38%; The molar concentration of the substance of the sodium carbonate solution is 0.2mol / L; The preparation method of the modified chitosan copper complex solution adopts the method described in Example 1;

[0052] Step 2, sealing the mixed solution, and placing it in an incubator at 80°C for 30 days to obtain a wet gel;

[0053] Step 3, placing the obtained wet gel in a trifluoroacetic acid (3vol.%) / acetone (97vol.%) solution for acidification and aging for 7 days;

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com