Hot-rolled steel sheet having excellent surface hardness after carburizing heat treatment and excellent drawability

A technology of tensile workability and surface hardness, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of unclear improvement effect, unresearched, no mention of cold workability, etc., to achieve extended life and difficult to crack. , the effect of improving the deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] [Preparation of molten steel]

[0129] First, predetermined alloy elements are added in a predetermined order to molten steel in which the dissolved oxygen amount and the total oxygen amount have been adjusted, whereby desired oxides can be formed. Especially in the present invention, it is extremely important to adjust the total oxygen amount after adjusting the dissolved oxygen amount so as not to form coarse oxides.

[0130] The so-called dissolved oxygen means free oxygen that does not form oxides but exists in molten steel. The term "total oxygen" means all the oxygen contained in molten steel, that is, the sum of free oxygen and oxygen forming oxides.

[0131] First, the dissolved oxygen content of molten steel is adjusted to a range of 0.0010% to 0.0060%. When the amount of dissolved oxygen in the molten steel is less than 0.0010%, the amount of dissolved oxygen in the molten steel is insufficient, so a predetermined amount of Al—O-based oxides cannot be secure...

Embodiment

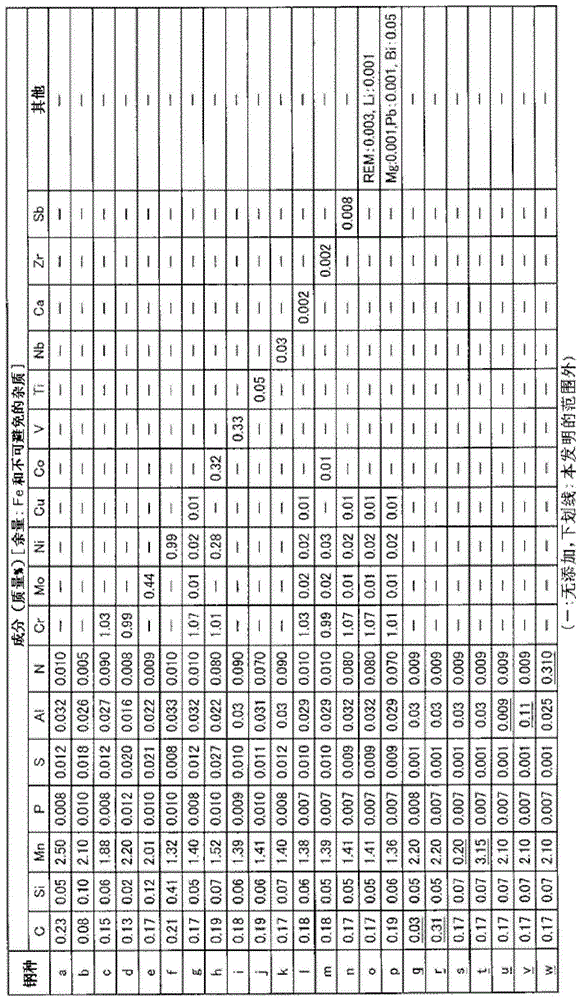

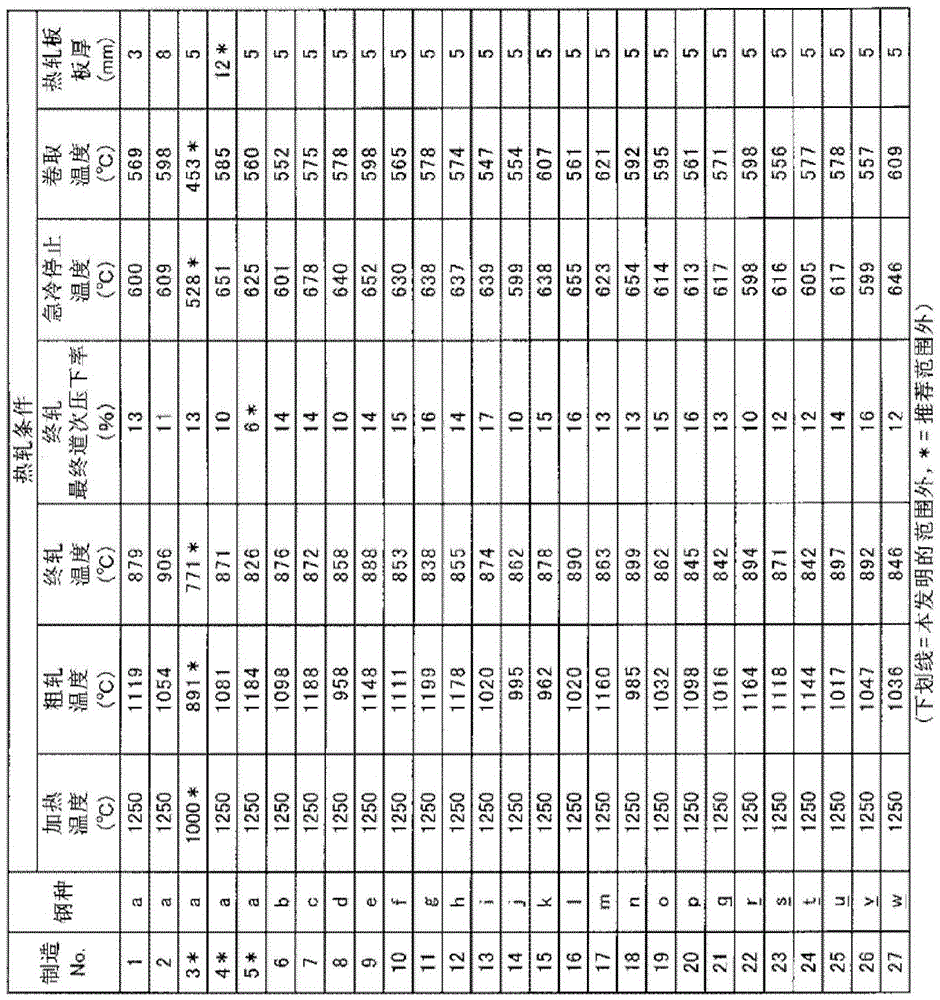

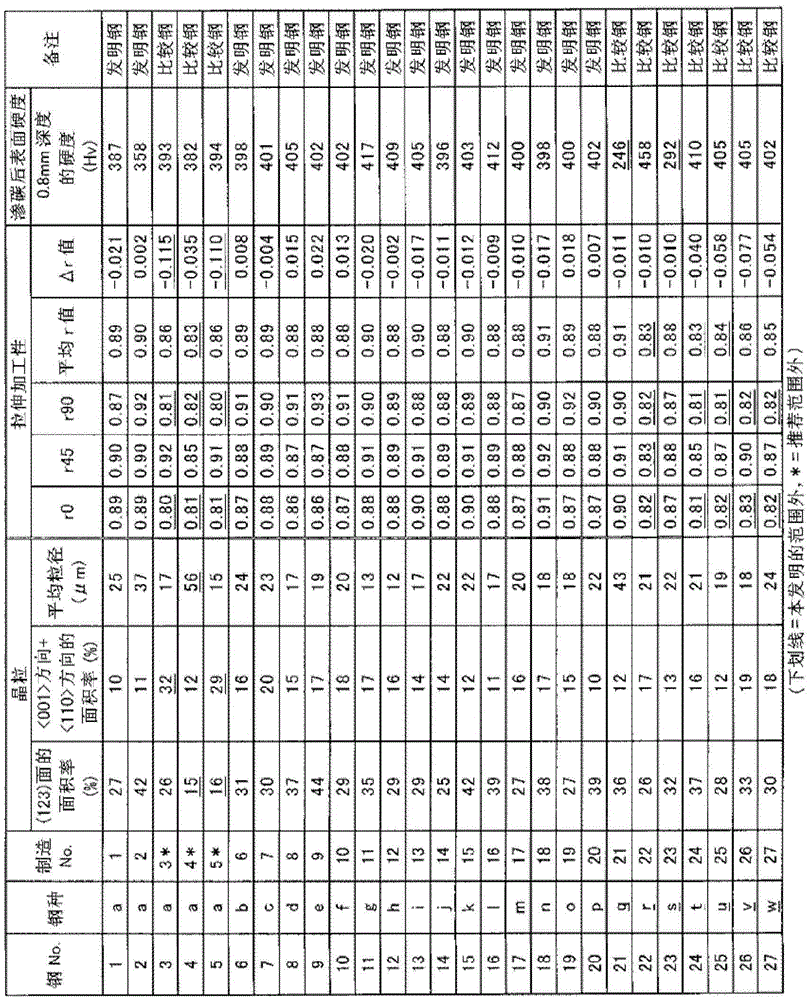

[0160] Steel with the composition shown in Table 1 below was melted by vacuum melting, cast into a steel ingot with a thickness of 120 mm, and hot-rolled under the conditions shown in Table 2 below to produce a hot-rolled steel sheet. In addition, in any of the tests, the cooling after the stop of rapid cooling was performed under the following conditions: slow cooling at a cooling rate of 10°C / s or less for 5 to 20 seconds.

[0161] Using a vacuum furnace (capacity 150 kg), the test steel containing the chemical composition shown in Table 1 was melted, cast into a 150 kg ingot, and cooled. When the test steel is smelted in a vacuum furnace, elements other than Al, REM, and Ca are adjusted for composition, and at least one element selected from C, Si, and Mn is used for deoxidation to adjust the dissolved oxygen content of molten steel. Stir the molten steel whose dissolved oxygen content has been adjusted for about 1 to 10 minutes to float and separate oxides in the molten st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com