Method for continuous adsorption and removal of carbonyl sulfide and dimethyl disulfide in carbon 4 left after etherification reaction

A technology of dimethyl disulfide and carbon four after ether, which is applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problem of reducing the content of dimethyl disulfide, and achieve simple equipment, The effect of mild adsorption conditions and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation of dimethyl disulfide adsorbent:

[0054] The NaY molecular sieve adsorbent loaded with 6wt% metal Ag was prepared as the adsorbent of dimethyl disulfide.

[0055] 1. Take by weighing 20g of NaY type molecular sieve carriers with a particle size of 2-3mm, and place it in an enamel dish, bake it at 540° C. in a muffle furnace for 3 hours, then take it out, and naturally drop to room temperature in the air;

[0056] II. Add the NaY molecular sieve carrier treated in step I to the AgNO 3 Aqueous solution (1.9gAgNO 3 Dissolve in 4mL deionized water), impregnate with equal volume at 40°C, and the impregnation time is 24 hours;

[0057] III. Rinse the NaY-type molecular sieve carrier treated in step II with deionized water three times, filter, dry the filtered product at 110°C for 2 hours, and then bake it in a muffle furnace at 540°C for 3 hours to prepare The NaY type molecular sieve adsorbent of loading 6wt% metal Ag, as the adsorbent of dimethyl disulfide, ...

Embodiment 1

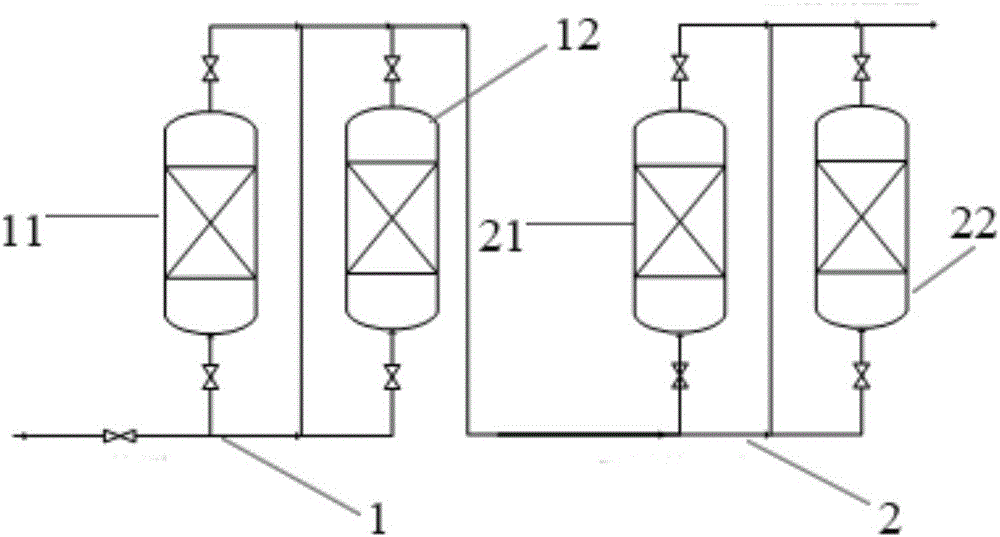

[0061] This embodiment provides a device for continuous adsorption and removal of carbonyl sulfide and dimethyl disulfide in carbon four after ether, the schematic diagram of which is shown in figure 1 As shown, the device includes a first desulfurization unit 1 and a second desulfurization unit 2;

[0062] The first desulfurization unit 1 includes a first carbonyl sulfide adsorption tower 11 and a second carbonyl sulfide adsorption tower 12, the first carbonyl sulfide adsorption tower 11 and the second carbonyl sulfide adsorption tower 12 are arranged in parallel, and the two can be switched mutually Use, when the carbonyl sulfide adsorbent X1 in the first carbonyl sulfide adsorption tower absorbs and breaks through, switch the carbon four behind the ether to the second carbonyl sulfide adsorption tower for adsorption and removal of carbonyl sulfide, and simultaneously treat the first carbonyl sulfide adsorption tower The carbonyl sulfide adsorbent that has been adsorbed and ...

Embodiment 2

[0065] This example provides a method for continuously adsorbing and removing carbonyl sulfide and dimethyl disulfide in C4 after ether, which is realized by using the device described in Example 1, wherein the method includes the following specific steps :

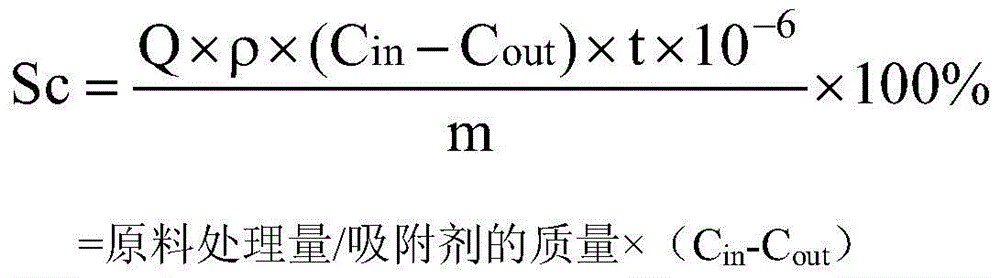

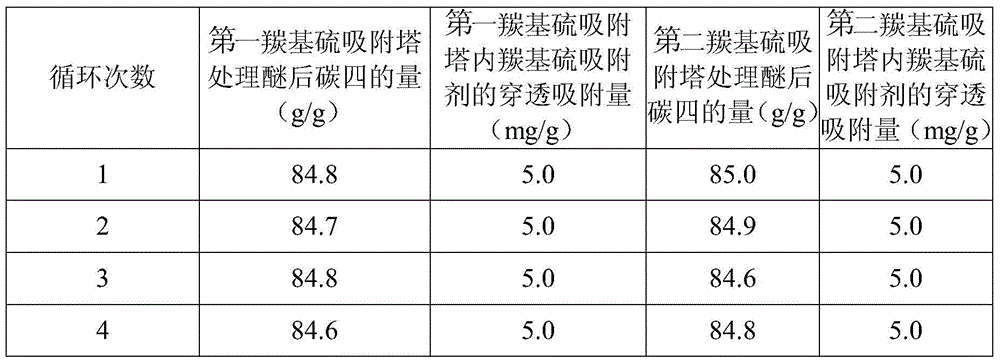

[0066] Both the first carbonyl sulfide adsorption tower and the second carbonyl sulfide adsorption tower are filled with 30mL of carbonyl sulfide adsorbent X 1 . At room temperature, pass C4 after ether with a COS content of 59 mg / g and a dimethyl disulfide content of 87 mg / g to the first carbonyl group of the carbonyl sulfide adsorption unit (the first desulfurization unit) at a rate of 60 mL / h. Sulfur adsorption tower, the fixed bed of the second carbonyl sulfide adsorption tower, after the treated ether, carbon four passes through the COS adsorbent from bottom to top X 1 , take samples from the upper part of the first carbonyl sulfide adsorption tower, take samples at regular intervals, and detect COS peaks in the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com