A kind of freeze-thaw stable type acrylate polymer emulsion and preparation method thereof

A polymer emulsion and acrylate technology, which is applied in the field of freeze-thaw stable acrylate polymer emulsion and its preparation, can solve the problems of long freeze-thaw recovery time, poor thickening ability, poor weather resistance, etc., and achieve freeze-thaw recovery time Short, high thickening efficiency, good freeze-thaw effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

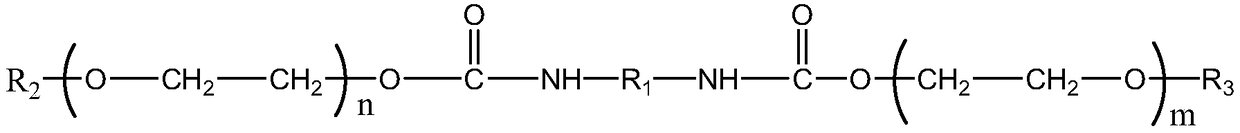

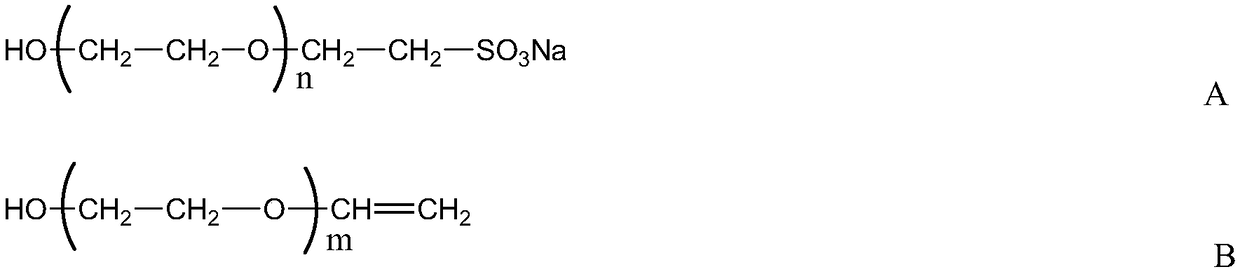

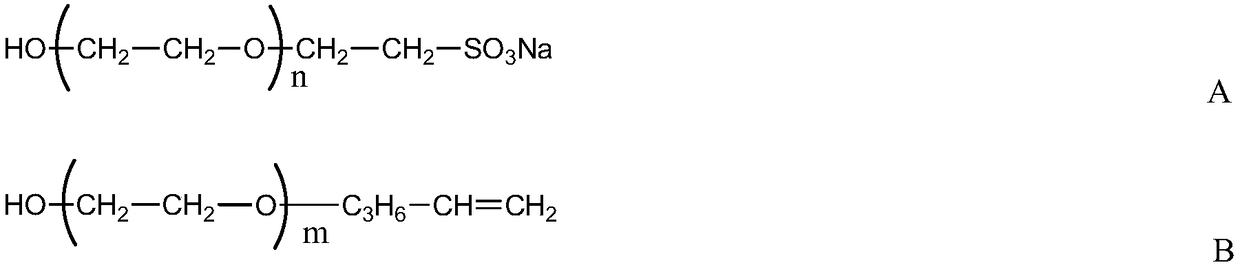

[0040] Preparation of polymerizable anionic bisamide surfactant: Dry the four-neck flask, stirrer, feeding tube and other instruments at 120°C for 3 hours, take them out and place them in a desiccator, and use them after cooling. Add 17.42g of toluene diisocyanate (TDI) to a four-necked flask with a stirrer and a thermometer, then dropwise add 102.8g of sodium sulfonate polyether (A), react for 2 hours, heat to 40°C under stirring, and add an appropriate amount of Dibutyltin dilaurate was used as a catalyst, and 92.4g of polyether (B) was added dropwise.

[0041] Continue to react for 2h. Then cool to 30° C., add distilled water and stir for 0.5 h, and add distilled water and surfactant solution at a concentration of 30 wt % to obtain a polymerizable bisamide surfactant (C).

[0042]

[0043] n is 20 and m is 20.

[0044] Preparation of alkali-soluble acrylate polymer: Add 1051g deionized water, 48g polymerizable bisamide surfactant (C), 10g sodium bicarbonate into a 2L f...

Embodiment 2

[0047] Preparation of polymerizable anionic bisamide surfactant: Dry the four-neck flask, stirrer, feeding tube and other instruments at 120°C for 3 hours, take them out and place them in a desiccator, and use them after cooling. Add 17.42 g of toluene diisocyanate into a four-neck flask equipped with a stirrer and a thermometer, and then dropwise add 56.8 g of sodium sulfate polyether (A). After reacting for 2 hours, heat to 40° C. under stirring, add an appropriate amount of dibutyltin dilaurate as a catalyst, and then add 61.4 g of polyether (B) dropwise.

[0048] Continue to react for 2h. Then cool to 30° C., add distilled water and stir for 0.5 h. After adding distilled water, the concentration of the surfactant is 30%, that is, a polymerizable bisamide surfactant (C) is obtained.

[0049]

[0050] n is 10 and m is 12.

[0051] Preparation of alkali-soluble acrylate polymer: add 1051g deionized water, 48g polymerizable bisamide surfactant (C), 10g sodium bicarbonate in...

Embodiment 3

[0054] Preparation of polymerizable anionic bisamide surfactant: Dry the four-neck flask, stirrer, feeding tube and other instruments at 120°C for 3 hours, take them out and place them in a desiccator, and use them after cooling. Add 16.82g of hexamethylene diisocyanate (HDI) to a four-necked flask with a stirrer and a thermometer, then dropwise add 135.8g of carboxylic acid sodium salt polyether (A), react for 2 hours and heat to 40°C while stirring. An appropriate amount of dibutyltin dilaurate was added as a catalyst, and 139.2 g of polyether (B) was added dropwise.

[0055] Continue to react for 2h. Then cool to 30° C., add distilled water and stir for 0.5 h. After adding distilled water, the concentration of the surfactant is 30%, that is, a polymerizable bisamide surfactant (C) is obtained.

[0056]

[0057] n is 28 and m is 30.

[0058] Preparation of alkali-soluble acrylate polymer: Add 1038g deionized water, 53g polymerizable bisamide surfactant (C), 12g sodium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com