Method for continuously preparing quantum dots through microchannel reactor

A technology of microchannel reactor and quantum dots, which is applied in the fields of chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problem that the continuous production of core-shell quantum dots cannot be realized, the CdSe quantum dot method needs to be improved, and the CdSe quantum dot Monodispersity is not high, to achieve the effects of industrial production, convenient production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

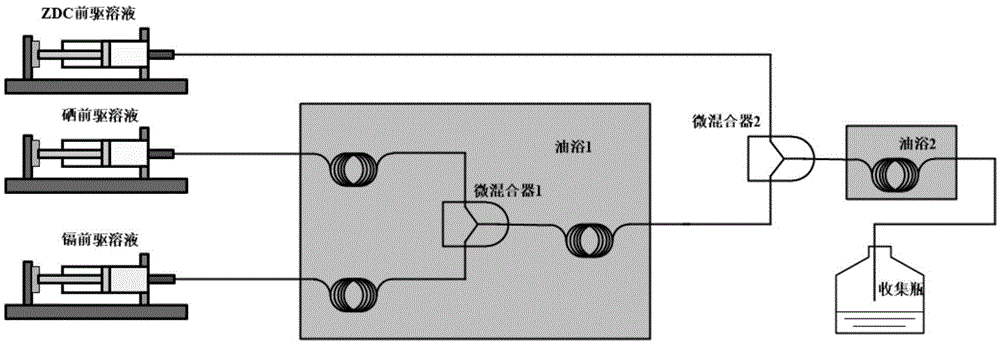

Method used

Image

Examples

Embodiment 1

[0038] (1) After weighing 0.0107g cadmium oxide (CdO) and 7.2228g oleylamine (OLA) in a beaker and mixing them, add 0.2mL oleic acid (OA) into the beaker, and then use 1-octadecene (ODE) to dissolve and dilute to 30mL; heat the beaker at 150°C for 1 hour to obtain a brownish-yellow transparent liquid, which is the cadmium precursor solution.

[0039] (2) Weigh 0.3948g of selenium powder (Se) in a beaker and add 4.5mL of trioctylphosphine (TOP), then dissolve and dilute to 30mL with 1-octadecene (ODE); heat the beaker at 90°C for 15min to obtain It is a colorless transparent liquid, which is the selenium precursor solution.

[0040] (3) 25 mL of the cadmium precursor solution and 25 mL of the selenium precursor solution were extracted with a syringe, and fed to the micromixer 1 through a polytetrafluoroethylene micropipe at 200 μL / min with a syringe pump.

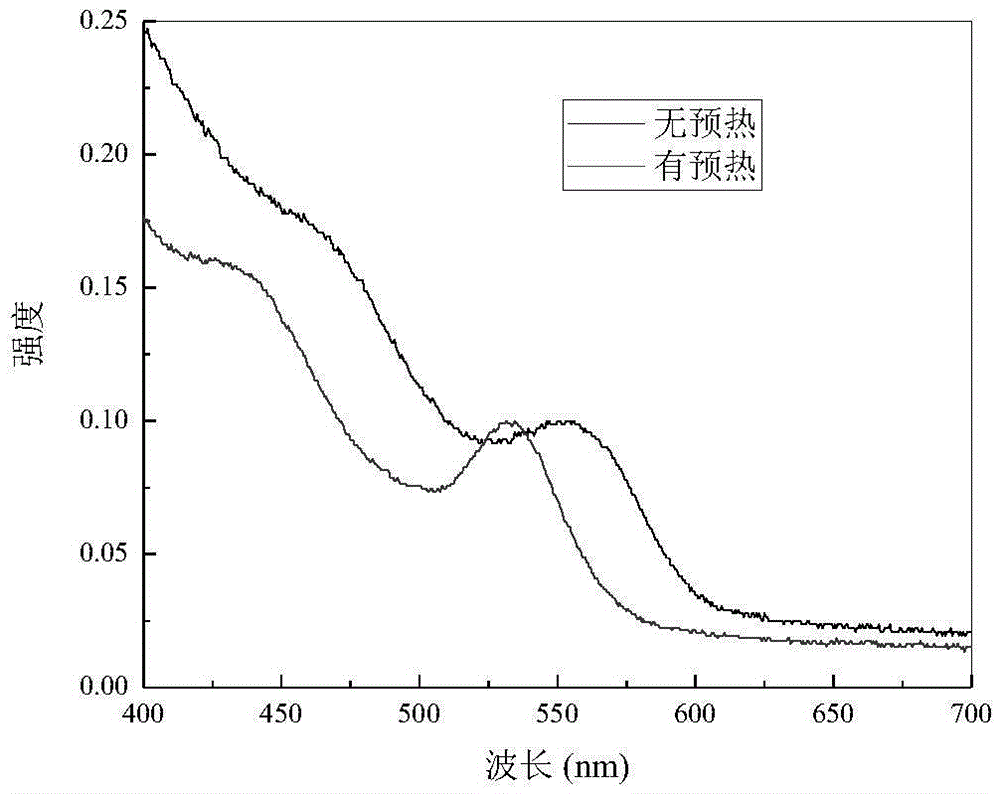

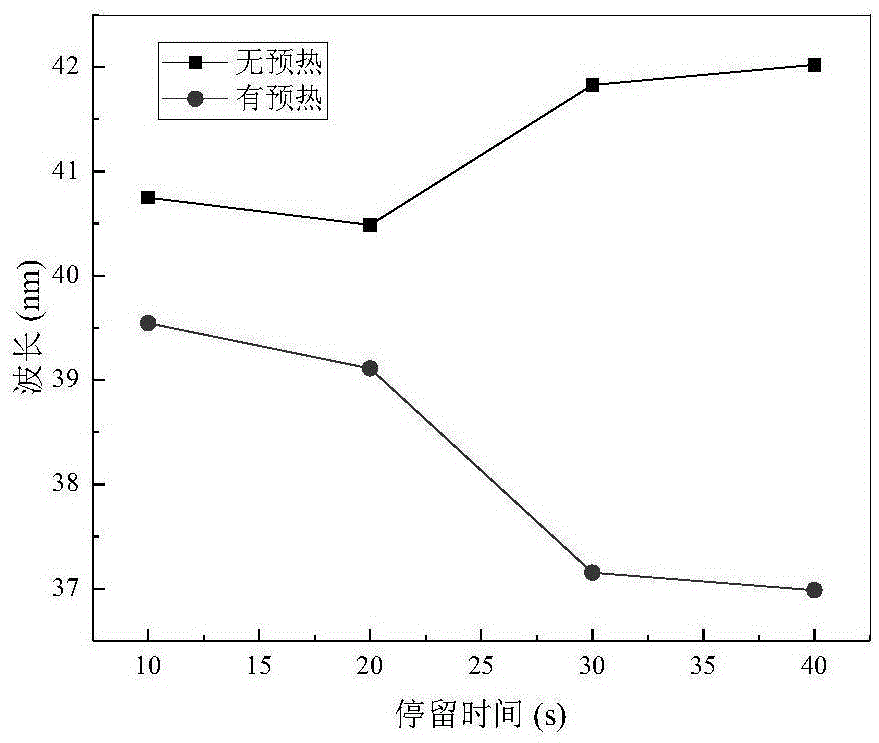

[0041] (4) Import the cadmium precursor solution and the selenium precursor solution into the oil bath 1, and carry out t...

Embodiment 2

[0050] (1) After weighing 0.0107g cadmium oxide (CdO) and 7.2228g oleylamine (OLA) in a beaker and mixing them, add 0.2mL oleic acid (OA) into the beaker, and then use 1-octadecene (ODE) to dissolve and dilute to 30mL; heat the beaker at 150°C for 1 hour to obtain a brownish-yellow transparent liquid, which is the cadmium precursor solution.

[0051] (2) Weigh 0.3948g of selenium powder (Se) in a beaker and add 4.5mL of trioctylphosphine (TOP), then dissolve and dilute to 30mL with 1-octadecene (ODE); heat the beaker at 90°C for 15min to obtain It is a colorless transparent liquid, which is the selenium precursor solution.

[0052] (3) 25 mL of the cadmium precursor solution and 25 mL of the selenium precursor solution were extracted with a syringe, and fed to the micromixer 1 through a polytetrafluoroethylene micropipe at 200 μL / min with a syringe pump.

[0053] (4) Lead the cadmium precursor solution and the selenium precursor solution into the oil bath 1, and carry out the...

Embodiment 3

[0058] (1) Weigh 0.0107g of cadmium oxide (CdO) and 7.2228g of oleylamine (OLA) in a beaker and mix them, then add 0.2mL of oleic acid (OA) into the beaker and mix, and then dissolve and dilute with 1-octadecene (ODE) to 30 mL; heat the beaker at 150°C for 1 hour to obtain a brownish-yellow transparent liquid, which is the cadmium precursor solution.

[0059] (2) Weigh 0.3948g selenium powder (Se) with a beaker and add 4.5mL trioctylphosphine (TOP) into the beaker and mix it, then use 1-octadecene (ODE) to dissolve and dilute to 30mL; put the beaker at 90 After heating at ℃ for 15 min, a colorless transparent liquid was obtained, which was the selenium precursor solution.

[0060] (3) Weigh 0.1056g zinc diethyldithiocarbamate (ZDC) with a beaker and add 1mL trioctylphosphine (TOP) to the beaker and mix, then add 1mL oleylamine (OLA) to the beaker and mix, then Use 1-octadecene (ODE) to dissolve and dilute to 20 mL; heat the beaker at 60°C for 15 minutes to obtain a colorless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com