Method for enhancing X-ray diffraction intensity of surface oxide layer of steel

A technique for diffraction intensity and steel surface, applied in material analysis using radiation diffraction, material analysis using wave/particle radiation, measuring devices, etc., can solve the problem of weak diffraction peaks of the oxide layer, difficulties in measuring and characterization of the oxide scale structure, etc. problem, to achieve the effect of increasing the diffraction intensity, weakening the matrix diffraction intensity, and enhancing the X-ray diffraction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Example 1: Take a hot-rolled SPHC steel plate with a thickness of 3.0mm, prepare samples as required, control the sample size, and the surface is ground and polished to meet the requirements described in step 1. The surface of the hot-rolled plate is treated by a heating furnace, and the heated After heating the furnace to 820°C, put the sample into it, keep it warm for 5 minutes, take it out, and air-cool it to room temperature in a non-protective atmosphere to oxidize the surface of the sample to prepare a sample with an oxide layer.

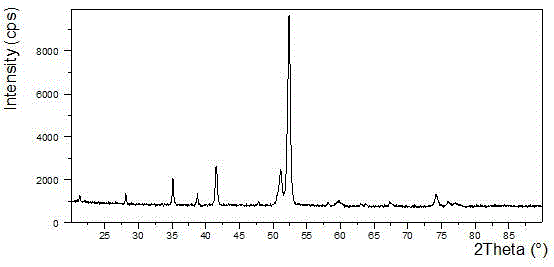

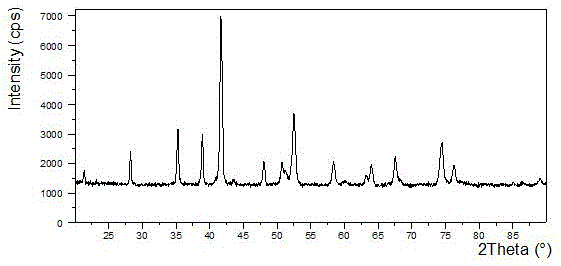

[0041] The sample is measured at a grazing incidence angle of 3°, and the X-ray diffraction pattern is obtained figure 2 , the analysis is mainly Fe 3 o 4 and Fe 2 o 3 . with regular scan mode figure 1 For comparison of the diffraction patterns of figure 2 The diffraction intensity of the medium Fe matrix is 3700cps, 2300cps after deducting the background, and the strongest peak intensity of the oxide layer is 7020cps, 5620cps...

example 2

[0042] Example 2: Take a hot-rolled SPHC steel plate with a thickness of 3.0mm, prepare samples according to the requirements, control the sample size, grind and polish the surface, and process the surface of the hot-rolled plate through a heating furnace. After heating the furnace to 820°C, put Put the sample in, take it out after keeping it warm for 5 minutes, and air-cool it to room temperature without a protective atmosphere to oxidize the surface of the sample to prepare a sample with an oxide layer.

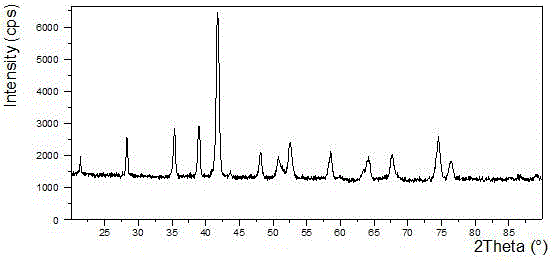

[0043] The sample is measured at a grazing incidence angle of 2°, and the X-ray diffraction pattern is obtained image 3 , the analysis is mainly Fe 3 o 4 and Fe 2 o 3 . with regular scan mode figure 1 For comparison of the diffraction patterns of image 3 The diffraction intensity of the medium Fe matrix is 2390cps, 940cps after deducting the background, and the strongest peak intensity of the oxide layer is 6440cps, 4990cps after deducting the background; figure ...

example 3

[0044] Example 3: Take a hot-rolled SPHC steel plate with a thickness of 3.0mm, prepare samples according to the requirements, control the sample size, grind and polish the surface, and process the surface of the hot-rolled plate through a heating furnace. After heating the furnace to 820°C, put Put the sample in, keep it warm for 5 minutes, take it out, and air-cool to room temperature in a non-protective atmosphere to oxidize the surface of the sample to prepare a sample with an oxide layer.

[0045] Measure the sample at a grazing incidence angle of 1.5° to obtain an X-ray diffraction pattern Figure 4 , the analysis is mainly Fe 3 o 4 and Fe 2 o 3 . with regular scan mode figure 1 For comparison of the diffraction patterns of Figure 4 The diffraction intensity of the medium Fe matrix is 1850cps, 350cps after deducting the background, and the strongest peak intensity of the oxide layer is 5960cps, 4460cps after deducting the background; figure 1 The diffraction in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com