Electric inductor and manufacturing method thereof

A production method and inductor technology, which is applied in the direction of inductors, inductors/transformers/magnets manufacturing, fixed inductors, etc., can solve the problems of difficulty in improving the degree of automation, and achieve technical difficulties, no obvious temperature changes, and good temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

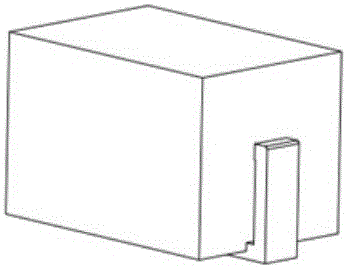

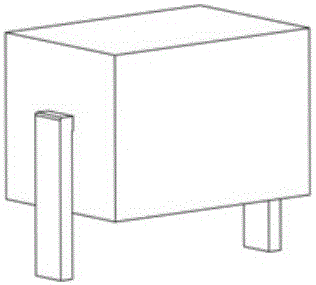

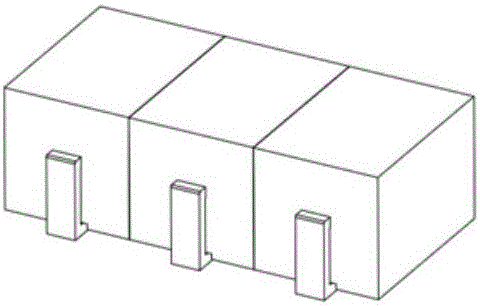

[0040] refer to Figure 3a to Figure 3g , in one embodiment, a method for manufacturing an inductor, comprising the following steps:

[0041] S1, put the conductor into the mold;

[0042] S2. Filling the mold with soft magnetic metal powder, and applying pressure to integrally press the soft magnetic metal powder and the conductor into a pressed body;

[0043] S3, performing heat treatment on the pressed body, so that the soft magnetic metal material has a predetermined degree of insulation resistance, and release the internal stress during pressing;

[0044] S4. Treat the heat-treated compacted body extending out of the oxide layer on the surface of the conductor of the magnet, so as to facilitate soldering with tin;

[0045] S5. Reshape the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com