Forming method of resistive random-access memory

A resistive random access and memory technology, applied in electrical components and other directions, can solve the problems of etching pollution of the sidewall of the upper electrode layer, and achieve the effects of avoiding oxidation of the material of the upper electrode layer, improving the quality and improving the etching selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

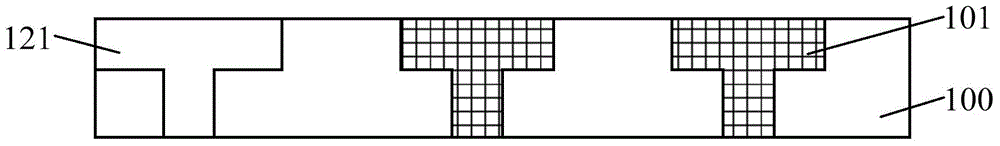

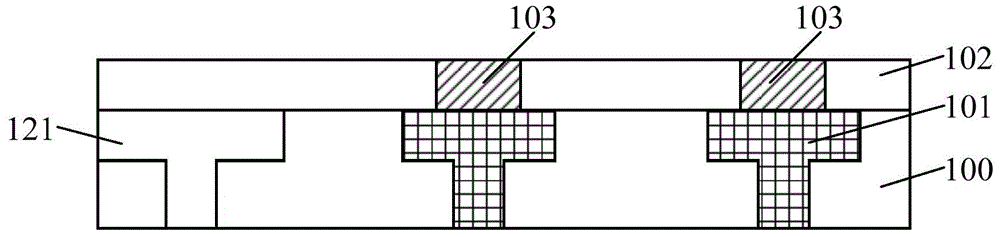

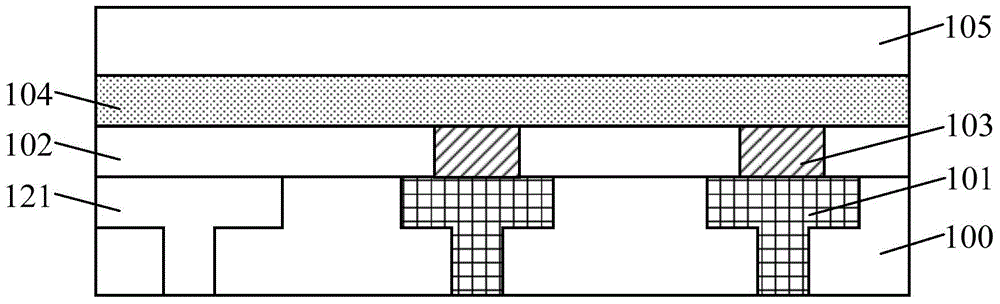

[0032] It can be seen from the background art that the electrical performance of the resistive random access memory formed in the prior art needs to be improved.

[0033] It has been found through research that in the prior art, after the upper electrode layer covering the surface of the dielectric material layer is formed, the method of physical sputtering bombardment is usually used to pattern the upper electrode layer and the dielectric material layer. The physical sputtering The bombardment source is Ar plasma, and openings are formed in the upper electrode layer and the dielectric material layer under the Ar plasma bombardment. However, due to the physical sputtering bombardment, the metal ions or metal ion groups of the upper electrode layer are separated from the upper electrode layer, and the medium ions or medium ion groups of the dielectric material layer are separated from the dielectric material layer; There is a lack of fluidity in the etching chamber, and it is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com