Preparing method for filter tip adsorption bar made of cellulose acetate open-cell micropore foam material

A technology of microporous foaming material and cellulose acetate, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of difficult melting processing and wide application, and achieve good smoke interception effect, low price, and high-quality equipment The effect of convenient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0026] 99 parts of cellulose triacetate, 1 part of polypropylene, 1 part of triethyl citrate, 5 parts of sodium carbonate, 4 parts of phosphite additives;

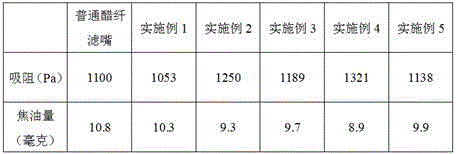

[0027] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature to 150°C, the temperature in the first stage to 175°C, the temperature in the second stage to 185°C, the temperature in the third stage to 195°C, and the temperature in the fourth stage to 200°C, the temperature of the fifth stage is 185°C, and the temperature of the die is 150°C. Add the mixture obtained in step (1), and then add 10 parts by mass of supercritical carbon dioxide in the second stage to extrude into a circular mold. , foaming at 240° C. for 5 minutes after extrusion to obtain filter adsorption sticks of cellulose acetate open-cell microporous foaming material. Adding the obtained round adso...

Embodiment 2

[0029] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0030] 70 parts of cellulose diacetate, 30 parts of polypropylene, 1 part of AC foaming agent;

[0031] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature at 175°C, the temperature at the first stage at 185°C, the temperature at the second stage at 195°C, the temperature at the third stage at 200°C, and the temperature at the fourth stage at 195°C, the temperature of the fifth section is 195°C, and the temperature of the die is 185°C. Add the mixed material obtained in step (1), and then add 1 mass part of supercritical carbon dioxide in the second section to extrude into a triangular mold. After extrusion, foam at 200° C. for 1 min to obtain a cellulose acetate open-pore microporous foam material filter adsorption rod. The obtained triangular adsorption stick is added to the filter to prepare cigarettes, and the ta...

Embodiment 3

[0033] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0034] 75 parts of cellulose acetate, 25 parts of polypropylene, 1 part of tributyl citrate, 3 parts of sodium bicarbonate foaming agent, 1 part of phosphite additive;

[0035] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature at 165°C, the temperature at the first stage at 170°C, the temperature at the second stage at 190°C, the temperature at the third stage at 195°C, and the temperature at the fourth stage at 200°C, the temperature of the fifth stage is 190°C, and the temperature of the die is 175°C. Add the mixture obtained in step (1), and then add 5 parts by mass of supercritical carbon dioxide in the second stage to extrude into a pentagonal mold. After extrusion, it is foamed at 230° C. for 2 minutes to obtain a filter adsorption rod of cellulose acetate open-cell microporous foam material. Adding the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com