Filter screen capable of realizing efficient oil-water separation, and method for preparing filter screen by femtosecond laser

An oil-water separation, femtosecond laser technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high filter screen cost, low use efficiency, complex processing technology process, etc. Stable structure, simple and efficient processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

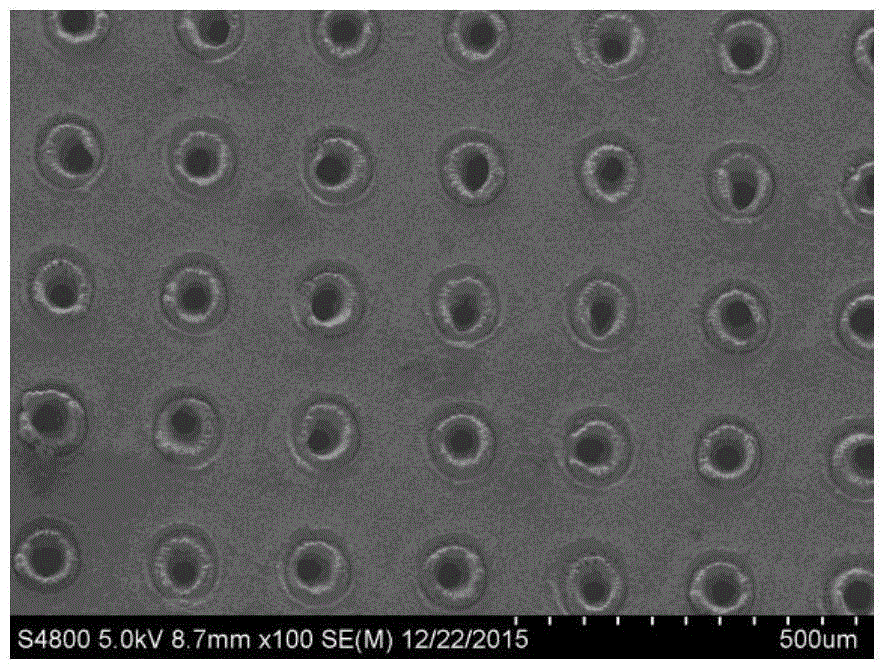

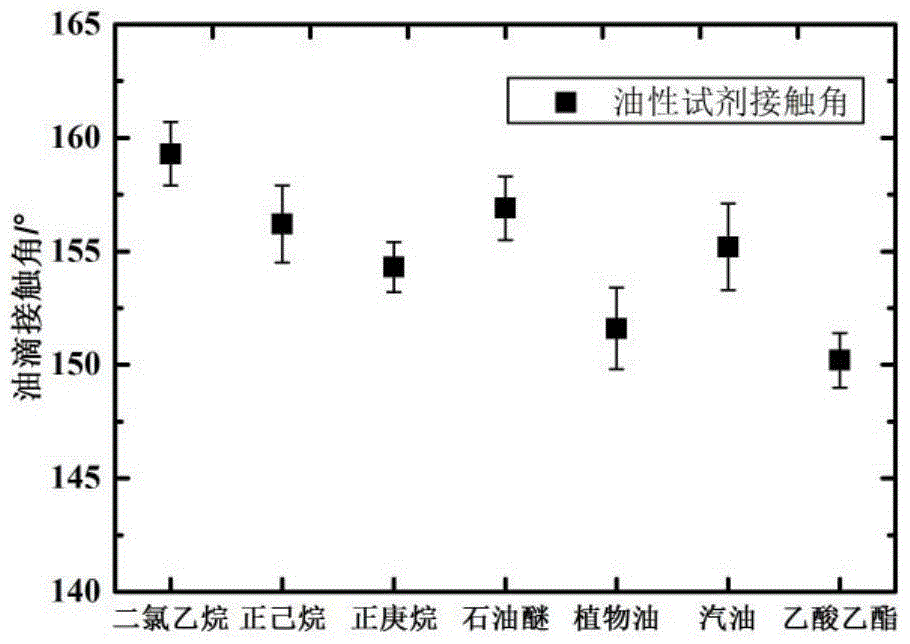

[0029] An oil-water separation filter screen prepared on a titanium foil material with a thickness of 100um, as attached figure 2 As shown, the titanium foil is evenly distributed with an array of micro-through holes, the pore diameter of the micro-holes is about 60um, and the distance between adjacent micro-holes is 200um, and a circle of recasting layer will be formed on the edge of the micro-holes to increase the size of the filter screen. Surface roughness improves the hydrophilicity and underwater oleophobicity of the filter screen. Good superhydrophilic and underwater superoleophobic properties can ensure that the filter screen can separate the aqueous solution from the oil-water mixture only under the action of gravity, realize oil-water separation, and have excellent oil-water separation efficiency.

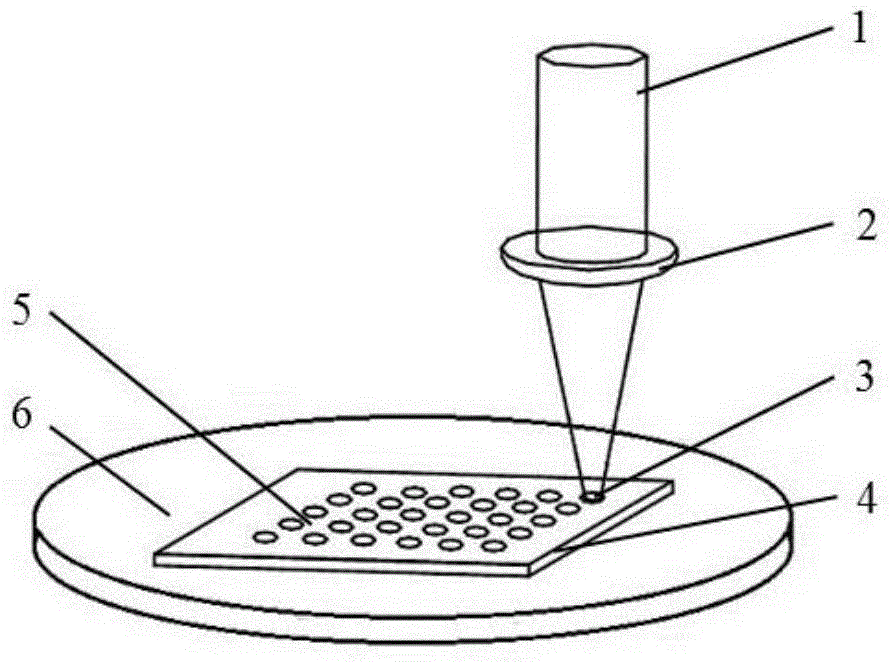

[0030] The oil-water separation filter screen in this embodiment is obtained by femtosecond laser processing, and the processing process includes the following steps:

...

Embodiment 2

[0038]An oil-water separation filter prepared on a cover glass material with a thickness of about 80um. The cover glass is evenly distributed with an array of micro-through holes. The spacing of the micropores is 100um, and some micron-sized and nano-sized particles are scattered on the edge of the micropores, which effectively increases the surface roughness of the filter screen and improves the hydrophilicity and underwater oleophobicity of the filter screen surface. Good superhydrophilic and underwater superoleophobic properties can ensure that the filter screen can separate the aqueous solution from the oil-water mixture only under the action of gravity, realize oil-water separation, and have excellent oil-water separation efficiency.

[0039] The oil-water separation filter screen in this embodiment is obtained by femtosecond laser processing, and the processing process includes the following steps:

[0040] Step 1: pretreat the selected cover glass material, and ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com