Air purification elimination agent

An air purification and elimination agent technology, applied in the direction of gas treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor selectivity, long processing time, elevated or long-term storage, etc., to reduce re-release , The effect of fast removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

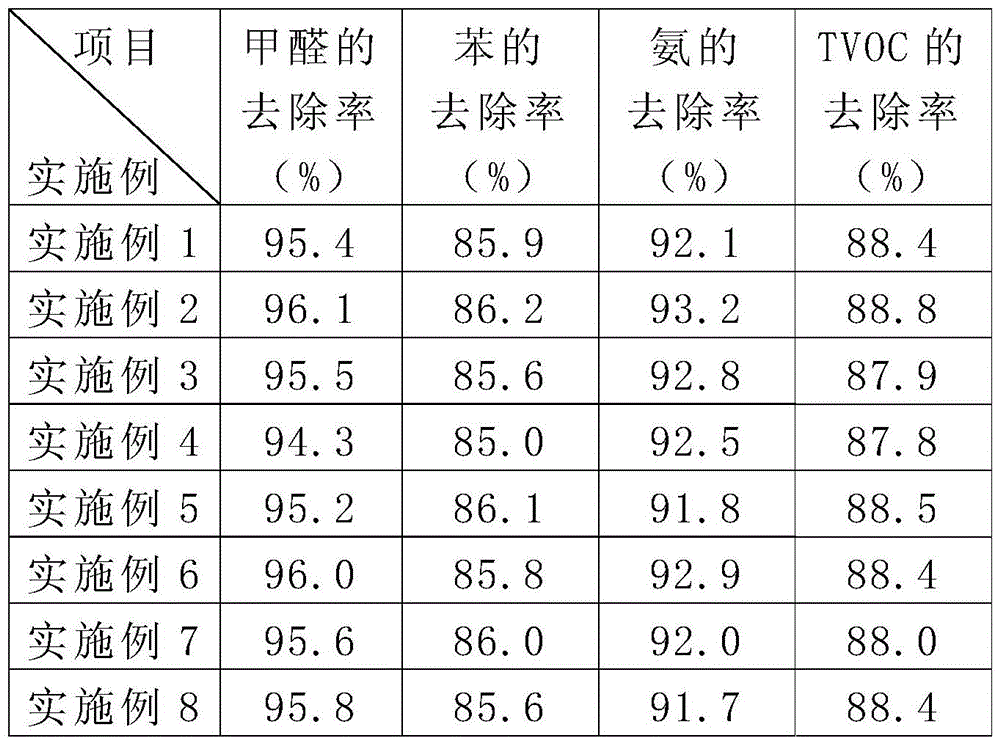

Examples

Embodiment 1

[0020] This air cleaning and eliminating agent comprises the composition of following mass percent (by 100wt%):

[0021] Sodium perchlorate: 4.5wt%; Potassium perchlorate: 4.0wt%; Sodium dihydrogen phosphate: 1.5wt%; Sodium bisulfate: 2.0wt%; Tripropylene glycol: 25wt%; Spherical water-absorbing resin: 20wt%; Wherein, the mass ratio of acrylic acid: acrylamide: sodium acrylate: maleic acid: sodium maleate: styrene: ethyl dimethylaminoacrylate in the spherical water-absorbing resin is 4:3:2:5:2:4:1.

[0022] The air purifying agent can be obtained by the following methods:

[0023] First, weigh the raw materials according to the above mass percentage ratio, dissolve sodium perchlorate, potassium perchlorate, sodium dihydrogen phosphate, sodium bisulfate and tripropylene glycol in water, and control the temperature at 20 ° C ~ 35 ° C, stir fully to dissolve After the base liquid is completely formed, transfer the base liquid into another container, put the spherical water-absor...

Embodiment 2

[0025] This air cleaning and eliminating agent comprises the composition of following mass percent (by 100wt%):

[0026] Sodium perchlorate: 3.0wt%; Potassium perchlorate: 3.0wt%; Sodium dihydrogen phosphate: 1.0wt%; Sodium bisulfate: 2.0wt%; Polypropylene glycol: 40wt%; Spherical water-absorbing resin: 10wt%; Wherein, the mass ratio of acrylic acid: acrylamide: sodium acrylate: maleic acid: sodium maleate: styrene: ethyl dimethylaminoacrylate in the spherical water-absorbing resin is 4:4:3:5:3:2:1.2.

[0027] The specific preparation method of this air-purifying and eliminating agent is consistent with embodiment 1, and will not repeat them here.

Embodiment 3

[0029] This air cleaning and eliminating agent comprises the composition of following mass percentage (by 100wt%)

[0030] Sodium perchlorate: 5.0wt%; Potassium perchlorate: 3.0wt%; Potassium hydrogen phosphate: 2.0wt%; Sodium tartrate: 1.0wt%; Tripropylene glycol: 25wt%; The mass ratio of acrylic acid: acrylamide: sodium acrylate: maleic acid: sodium maleate: styrene: ethyl dimethylaminoacrylate in the spherical water-absorbing resin is 5:5:3:4:3:1:1.

[0031] The specific preparation method of this air-purifying and eliminating agent is consistent with embodiment 1, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com