Tea polyphenol preservative and using method thereof

A technology of tea polyphenol powder and preservative, which is applied in wood treatment, pressure impregnation, wood processing equipment and other directions, can solve the problems of difficult purification, large scale of technical investment, low industrial productivity, etc., and achieves excellent anti-corrosion effect and antibacterial effect. Good effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

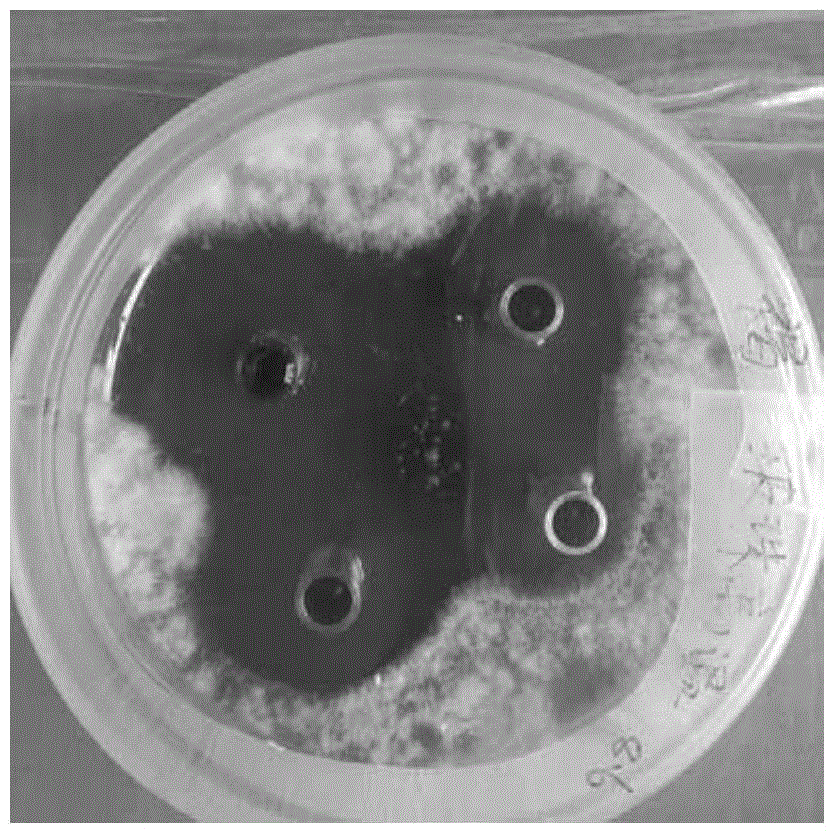

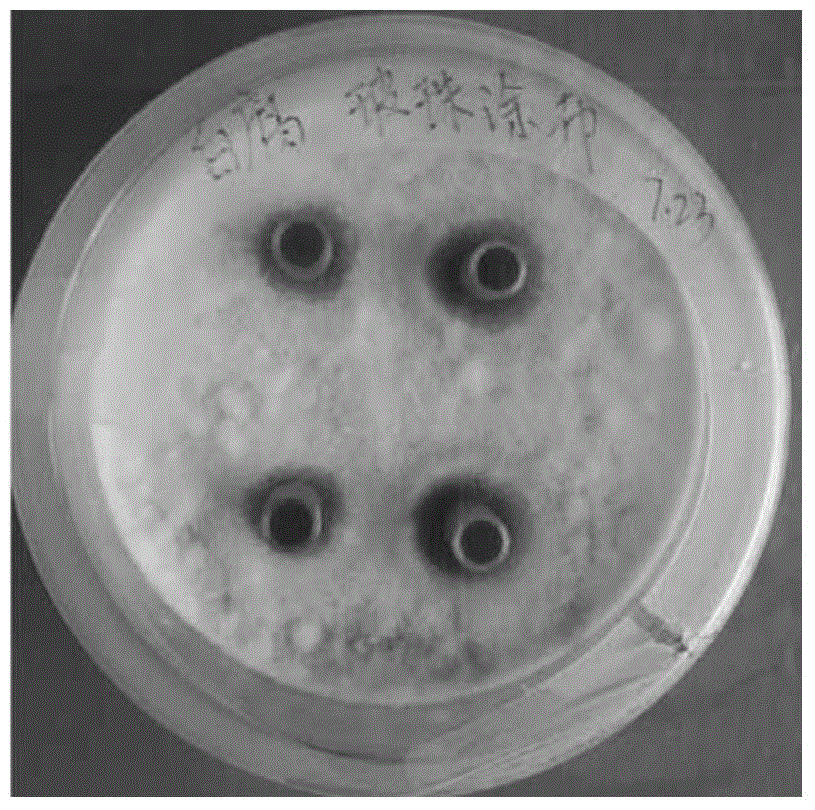

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: The tea polyphenol preservative is made of water-soluble tea polyphenol powder and sterile distilled water, and the mass percentage concentration of the water-soluble tea polyphenol powder is 5%, 10%, 15% or 20%; The mass content of the effective substance of the water-soluble tea polyphenol powder is 95%.

specific Embodiment approach 2

[0024] Specific embodiment 2: The tea polyphenol preservative in this embodiment is formed by dissolving water-soluble tea polyphenol powder in distilled water at room temperature, and then treating it for 20 minutes under steam conditions with a pressure of 0.2 MPa and a temperature of 121°C. wherein the mass content of the water-soluble tea polyphenol powder effective substance is 95%, and the mass percentage concentration of the water-soluble tea polyphenol powder is 5%, 10%, 15% or 20%.

specific Embodiment approach 3

[0025] Specific embodiment three: in this embodiment, the tea polyphenol preservative is to dissolve the water-soluble tea polyphenol powder in sterile distilled water, then add VE (vitamin E), and the mass percentage concentration of the water-soluble tea polyphenol powder is 5%. , 10%, 15% or 20%, the mass percent concentration of VE is 0.05%, and the mass content of the effective substance of the water-soluble tea polyphenol powder is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com