An aluminum electrolytic cell waste slag comprehensive treatment system

A treatment system and comprehensive treatment technology, applied in the field of comprehensive treatment system for aluminum electrolytic cell waste slag, can solve the problems of waste of resources, failure to realize recycling and reuse of useful resources, etc., and achieve the effect of saving equipment costs and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

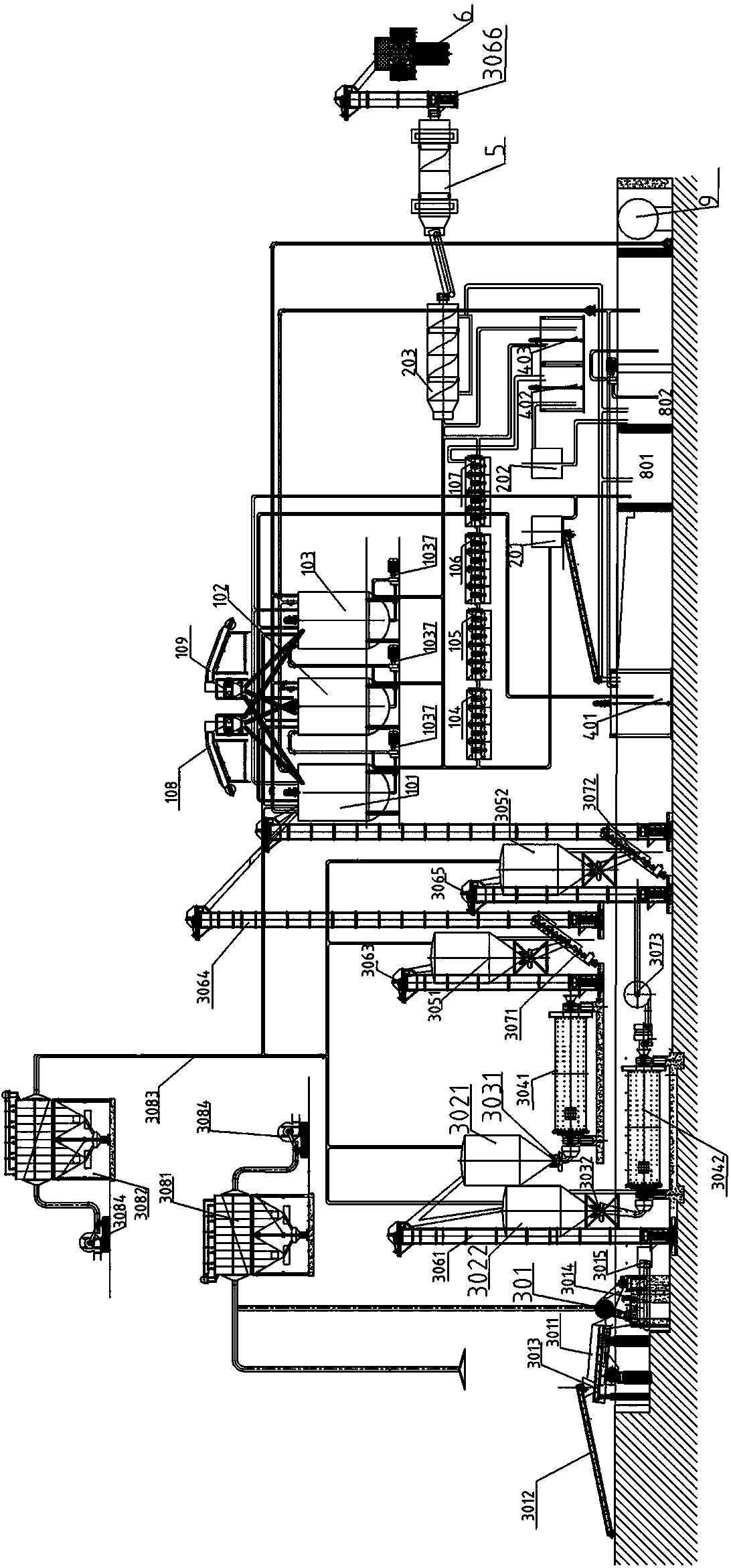

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

[0044] The overhaul slag of the present invention is the remaining part after removing the steel rod and the cathode carbon block from the lining of the electrolytic aluminum waste tank, and contains soluble fluoride and a small amount of cyanide.

[0045] The waste carbon slag of the present invention is the waste slag produced by the carbon block peeled off from the anode during the electrolytic aluminum production process, which falls into the molten electrolyte and floats on the surface of the molten electrolyte. The main components are carbon and electrolyte, and the electrolyte is mainly cryolite.

[0046] The cathode carbon block of the present invention is the waste material produced during the overhaul of the electrolytic cell as the carbon used as the cathode in the electrolysis process. The main components are carbon and sodium fluoride, and als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com