A method of degrading organic pollutants in waste water through a Fenton-like process

A technology for degrading organic pollutants and sewage, applied in the field of degrading organic pollutants, can solve the problems of secondary pollution, narrow effective pH range, low activity and stability, etc., and achieve good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

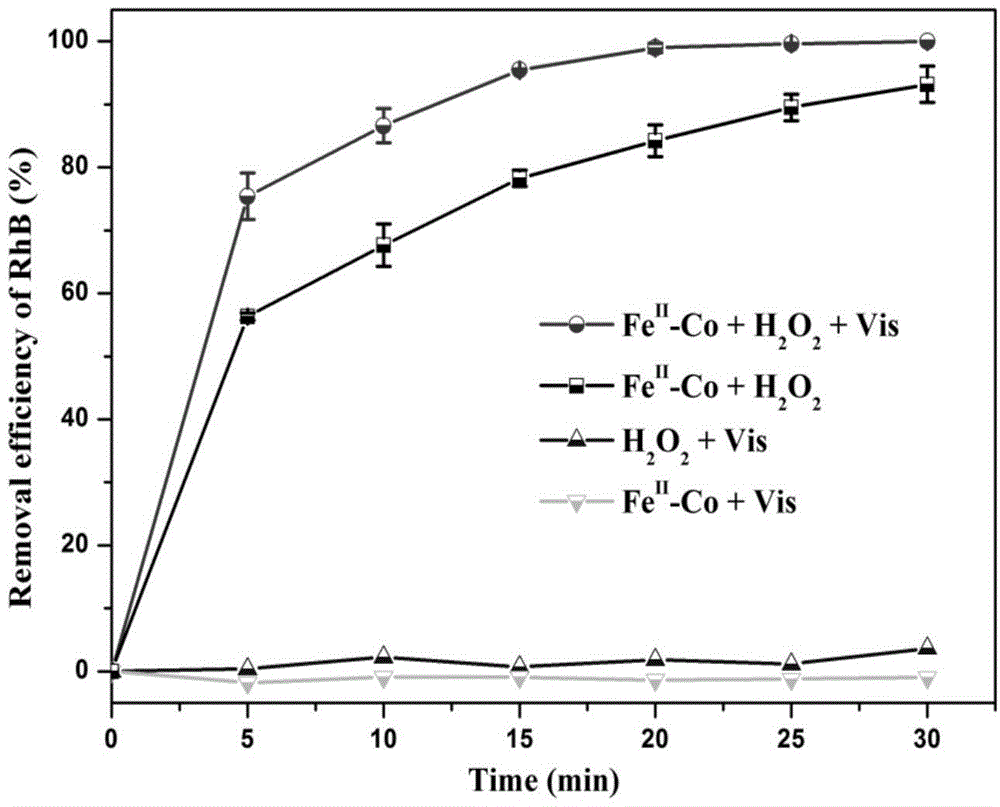

[0019] Using Fe-CoPBAs-H 2 o 2 / PMS Fenton-like reaction system to degrade RhB in simulated sewage. Take Fe 3 [Co(CN) 6 ] 2 12H 2 O0.2g was added to 50mL of simulated wastewater, wherein the concentration of RhB was 12mgL -1 , after stirring for 30 min, add 20 μL H 2 o 2 (12M), start the reaction. In the absence of light, the degradation efficiency of RhB can reach 95% in 30 minutes; under the irradiation of visible light (MAX-303 xenon lamp, add a 400nm filter to filter out ultraviolet light), the degradation efficiency of RhB can reach 100% in 20 minutes. %.

Embodiment 2

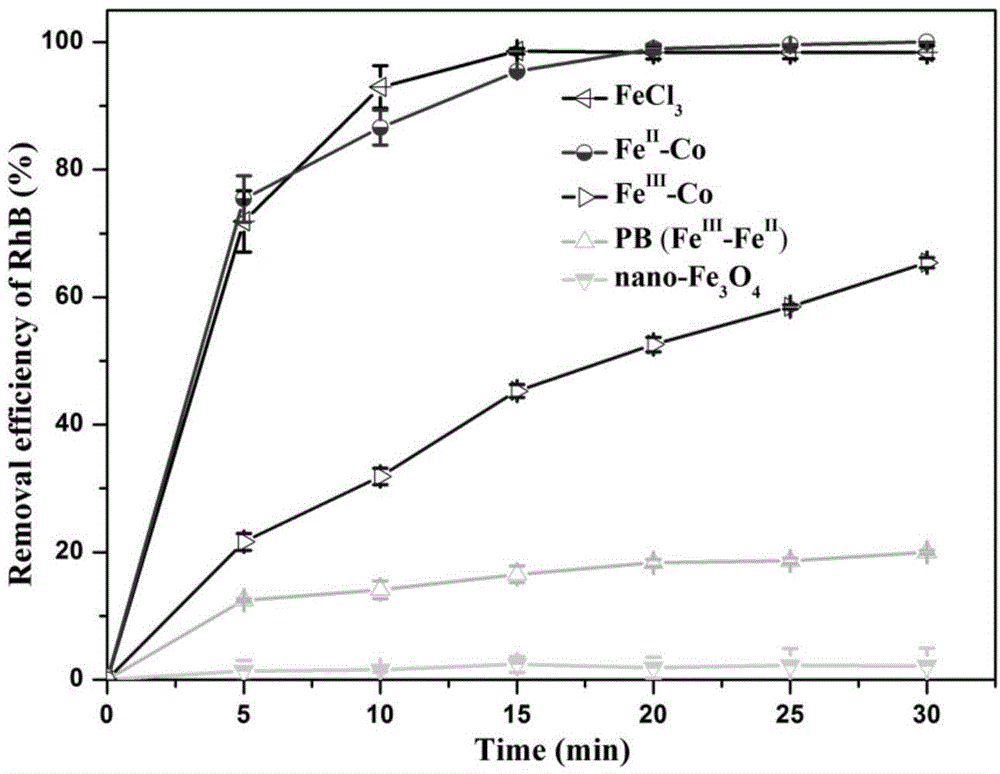

[0021] Fe-CoPBAs-H 2 o 2 / PMS-like Fenton reaction system for degrading RhB in simulated sewage compared with other Fenton reaction systems. Experimental conditions: catalyst concentration 0.2g / L, RhB concentration 12mg / L, H 2 o 2 An aqueous solution with a concentration of 4mmol / L, pH=4.8, irradiated with visible light from a MAX-303 xenon lamp. Its degradation efficiency of RhB is much higher than that of iron oxide-H 2 o 2 Reaction system, and PB-H 2 o 2 Fenton reaction system.

Embodiment 3

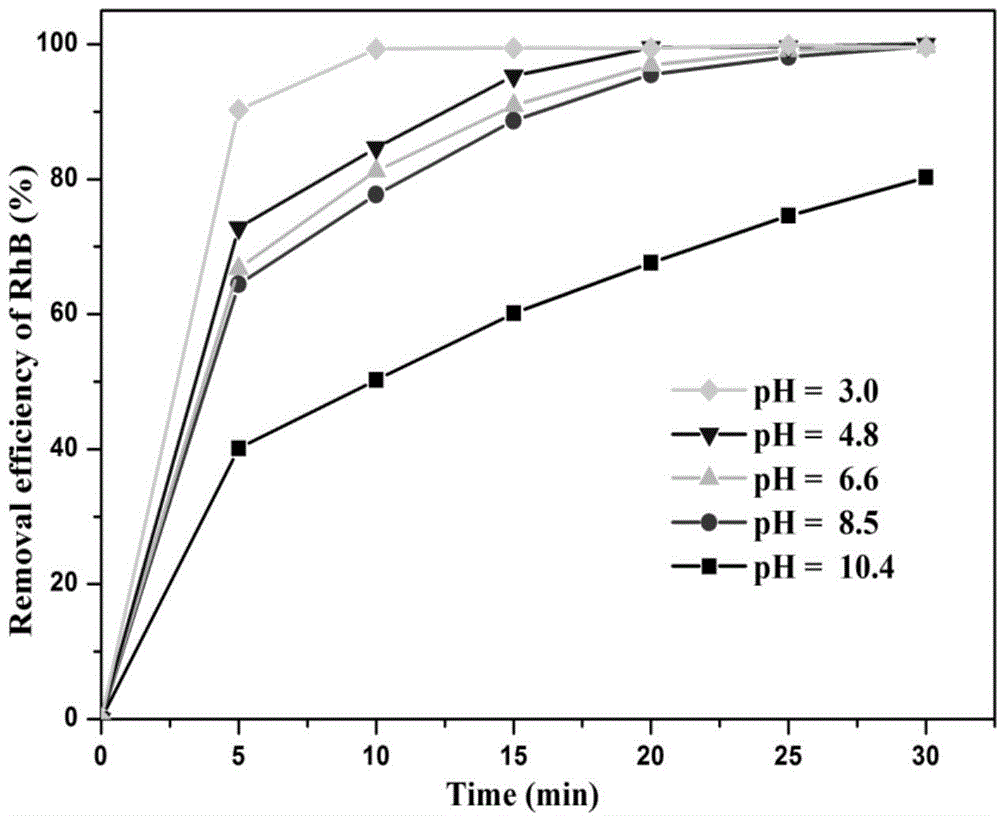

[0023] to Fe-CoPBAs-H 2 o 2 Investigation of the effect of different simulated sewage pH on the activity of / PMS-like Fenton reaction system. Experimental conditions: catalyst concentration 0.2g / L, RhB concentration 12mg / L, H 2 o 2 Concentration of 4mmol / L aqueous solution, MAX-303 xenon lamp visible light irradiation. By changing the initial pH of the reaction and simulating sewage with different pH, it was found that it has a good degradation effect on RhB with different pH. When the pH is between 2 and 9, the degradation efficiency of RhB can reach 100% within 30 minutes. When pH=10.4, the degradation efficiency of RhB can reach 84% within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com