Oilfield Produced Water Resource Reuse Steam Injection Boiler Treatment System

A technology of a steam injection boiler and a treatment system, which is applied in the field of a steam injection boiler treatment system for water resource recovery in oilfield production, can solve the problems of large consumption of fresh water resources, loss of thermal energy resources, immature treatment process flow, etc., to improve treatment efficiency. , Improve effluent quality and solve the effect of resource treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

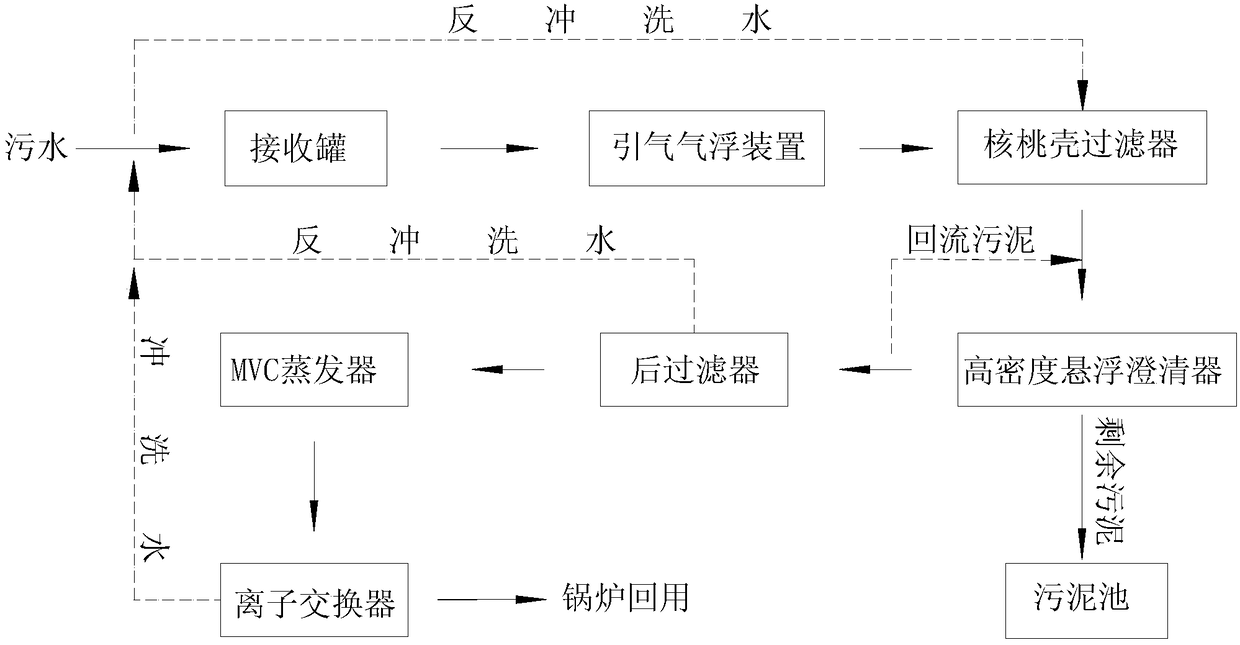

[0019] Such as figure 1 As shown, the steam injection boiler treatment system for the recovery of oilfield produced water resources includes a receiving tank, an air flotation device, a filter, a high-density suspension clarifier, an MVC evaporator, and an ion exchanger. The outlet of the receiving tank is lifted The pump is connected to the inlet of the bleed air flotation device, the outlet of the bleed air flotation device is connected to the inlet of the high-density suspension clarifier through a filter, and the outlet of the high-density suspension clarifier is connected to the MVC evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com