Preparation method of perylene pigment

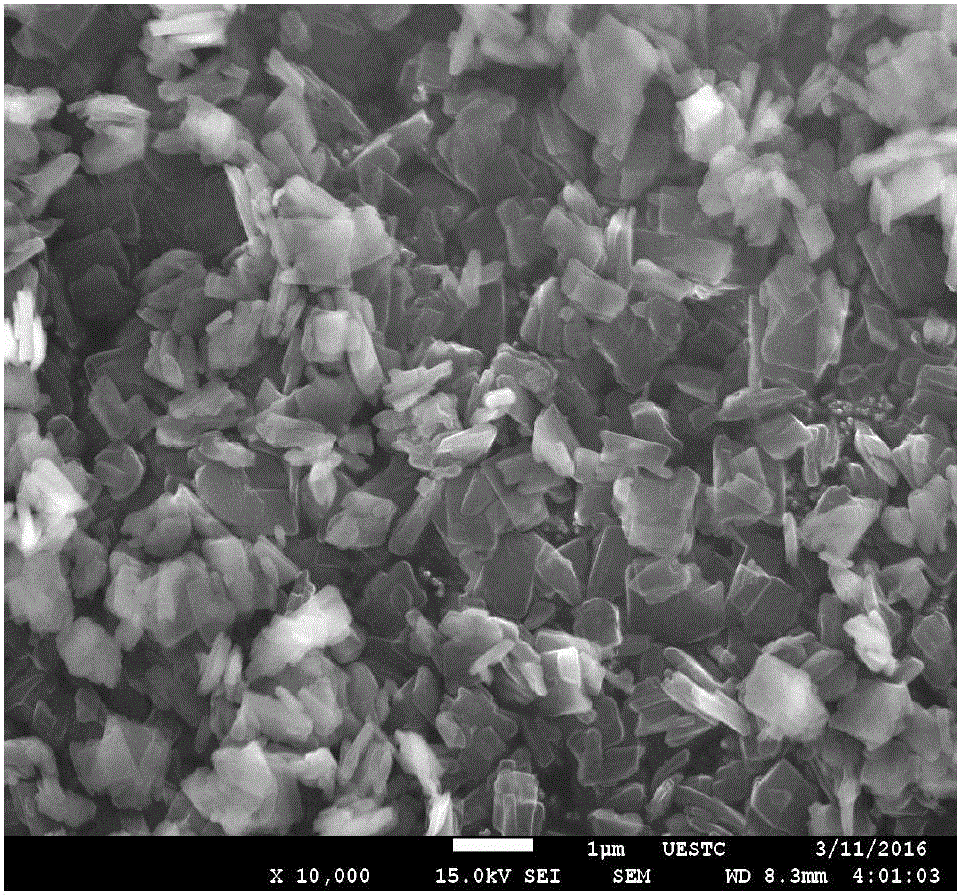

A pigment and perylene-based technology, applied in the field of preparation of perylene-based pigments, can solve the problems of high cost, must be recycled, environmental hazards, etc., and achieve the effect of simple method, strong hiding power, and uniform crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Add 4ML benzylamine to 50ML glycerol solution, seal it, and sonicate for 30 minutes to obtain a mixed solution.

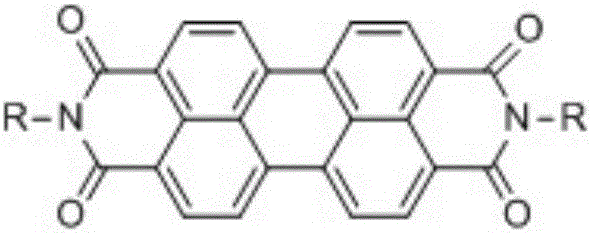

[0026] Step 2: Transfer the mixed solution obtained in Step 1 to a stainless steel reaction kettle at 50°C, add 5g of perylene-3,4,9,10-tetracarboximide, and heat for 30 minutes under stirring at 1000 rpm, the perylene -3,4,9,10-Tetracarboximide is fully dissolved and the solution is red.

[0027] Step 3: After raising the reaction temperature obtained in Step 2 to 140° C., seal and reflux successively, and keep the reaction for 4 hours under stirring at 2000 rpm.

[0028] Step 4: After step 3 is completed, adjust the reaction temperature to 50°C, cool naturally, add 25ML pure methanol to dilute, wash with water, filter, and dry at 60°C.

[0029] Step 5: Add the dry solid obtained in step 4 to 100ML mass fraction 10%Na 2 CO 3 , after ultrasonic dissolution, transferred to a 50°C reactor for reflux reaction for 1h, then cooled naturally, washed wit...

Embodiment 2

[0031] Step 1: Add 4ML phenethylamine to 50ML glycerol solution, seal it, and ultrasonicate for 30 minutes to obtain a mixed solution.

[0032] Step 2: Transfer the mixed solution obtained in Step 1 to a stainless steel reaction kettle at 40°C, add 5 g of perylene-3,4,9,10-tetracarboximide, and heat for 30 minutes under stirring at 1500 rpm. Ethylamine and perylene-3,4,9,10-tetracarboximide were fully dissolved, and the solution was red.

[0033] Step 3: After raising the reaction temperature obtained in Step 2 to 140° C., seal and reflux successively, and keep the reaction for 4 hours under stirring at 2000 rpm.

[0034] Step 4: After step 3 is completed, adjust the temperature to 50°C, add 25ML of pure methanol to dilute, wash with water, filter, and dry at 60°C.

[0035] Step 5: Add the dry solid obtained in step 4 to 100ML mass fraction 10%Na 2 CO 3 , after ultrasonic dissolution, transferred to a 50°C reactor for reflux reaction for 1h, then cooled naturally, washed wi...

Embodiment 3

[0037] Step 1: Add 5.2 g of 4-methoxybenzylamine to 50 mL of glycerol solution, seal it, and ultrasonicate for 30 minutes to obtain a mixed solution.

[0038] Step 2: Transfer the mixed solution obtained in Step 1 to a stainless steel reaction kettle at 50°C, add 5g of perylene-3,4,9,10-tetracarboximide, and heat for 30 minutes under stirring at 1000 rpm, the perylene -3,4,9,10-tetracarboximide and 4-methoxybenzylamine are fully dissolved, and the solution is red.

[0039] Step 3: After raising the reaction temperature obtained in Step 2 to 140° C., seal and reflux successively, and keep the reaction for 4 hours under stirring at 2500 rpm.

[0040] Step 4: After step 3 is completed, adjust the temperature to 50°C, add 25ML of pure methanol to dilute, wash with water, filter, and dry at 60°C.

[0041] Step 5: Add the dry solid obtained in step 4 to 100ML mass fraction 10%Na 2 CO 3 , after ultrasonic dissolution, transferred to a 50°C reactor for reflux reaction for 1 hour, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com