Polyurethane-modified daub for leaking stoppage

A technology of polyurethane modification and plugging glue, applied in the field of polyurethane materials, can solve the problems of easy crack expansion, strong odor and high corrosion, and achieve the effect of ensuring repairing effect, good operation safety and fast curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

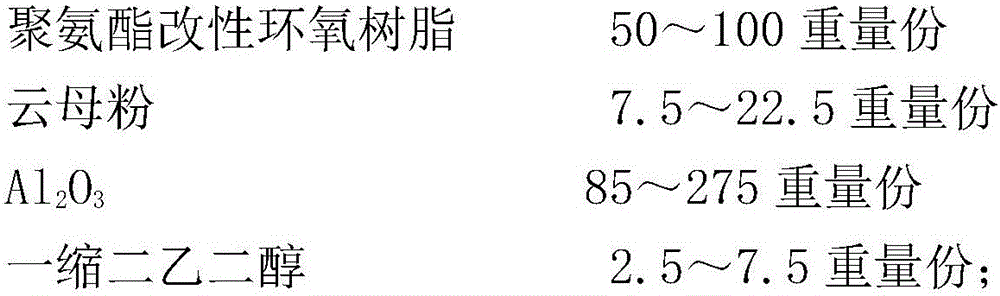

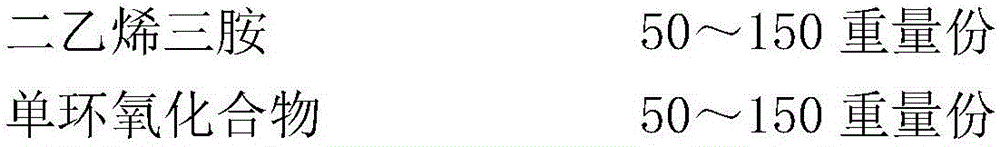

[0030] 1. Preparation of component A

[0031] Add polyether to the reaction kettle, heat to 115-120°C, vacuum dehydrate for 2 hours, cool down and set aside;

[0032] Add polyether to the reaction kettle, heat to 115-120°C, vacuum dehydrate for 2 hours, and obtain dehydrated polyether after cooling;

[0033] Add polyisocyanate to the reaction kettle, heat to 60°C, stir, then add the dehydrated polyether, the weight ratio of the polyisocyanate to the dehydrated polyether is 100:5-20, keep warm at 80°C, when the reaction material NCO in - When the group content is 5%, the reaction is stopped, and the prepolymer is obtained after cooling;

[0034] Add the epoxy resin to the reaction kettle, the weight ratio of the epoxy resin to the prepolymer is 100:5-20, then add the prepolymer, react at 80°C for 3 hours, discharge, and cool to 40°C ℃ or below, to obtain polyurethane modified epoxy resin.

[0035] Add diethylene glycol to the polyurethane modified epoxy resin, stir evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com