Hydrogenated hot gas chemical solution component and application thereof in increasing yield of horizontal well

A chemical solution, horizontal well technology, applied in the direction of chemical instruments and methods, wellbore/well components, drilling composition, etc., can solve the problem of near-well-area treatment not applicable to horizontal oil and gas wells, and near-well-hole permeability reduction , mining interruption and other problems, to achieve the effect of technical safety, reliability, low cost, and solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

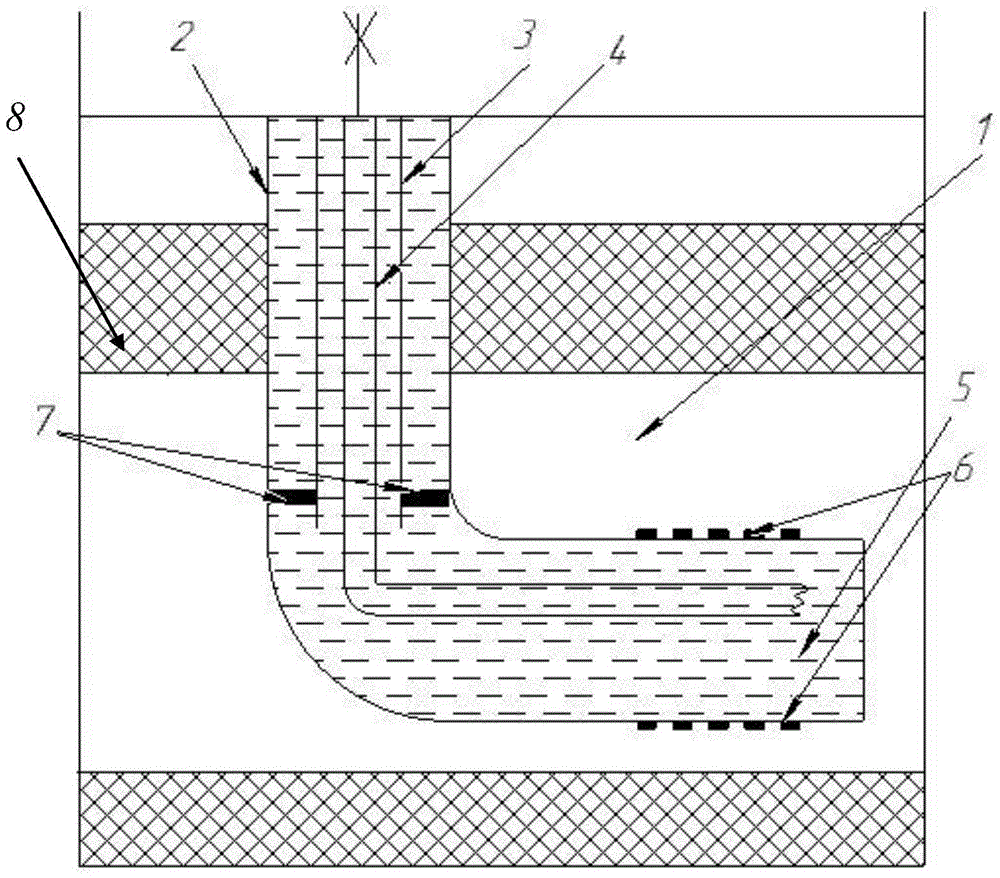

[0035] Example 1: Hydrogenation hot gas chemical stimulation test of No. 1 oil well in an oilfield in Xinjiang

[0036] Geological conditions and related parameters of oil well No. 1: reservoir series sandstone and siltstone; medium-porosity and low-permeability oil layers; inner diameter of casing 2 Tubing 3 inner diameter The bottom of the artificial well is 4743m from the ground, the length of the horizontal oil well is 4102-4743m, and the perforation range in the horizontal oil well is 4556.0-4582.0m; the daily fluid production before the stimulation operation is 0.8t, of which the daily oil production is 0.2t;

[0037] From the above data, it can be concluded that the volume of the reaction zone is 7250L. Prepare No. 1 solution 4000L or 5200kg, No. 2 solution 3250L or 5200kg.

[0038] Solution No. 1 contains: Ammonium Nitrate NH 4 NO 3 , hydrocarbon fuel, sodium chloride NaCl, nitric acid HNO 3 , emulsifier, and the respective mass percentages of water: 55%, 13%, 5...

Embodiment 2

[0044] Example 2: Hydrogenation hot gas chemical stimulation test of No. 2 oil well in an oilfield in Xinjiang

[0045] Geological conditions and related parameters of oil well No. 2: reservoir series sandstone and siltstone; medium-porosity and low-permeability oil layers; inner diameter of casing Tubing 3 inner diameter The artificial well bottom is 4933m; the horizontal well section is 4530-4933m; the perforation range is 4808.5-4918m; the daily fluid production before the stimulation operation is 2.9t, of which the daily oil production is 1.3t.

[0046] From the above data, the volume of the reaction zone is 4500L. Prepare 2500 liters or 3200 kg of No. 1 solution and 2000 liters or 3200 kg of No. 2 solution.

[0047] Solution No. 1 contains: Ammonium Nitrate NH 4 NO 3 , hydrocarbon fuel, potassium chloride KCl, nitric acid HNO 3 , emulsifier, and water respectively by mass percentage: 53%, 13%, 4.5%, 9%, 1%, 19.5%. The mass of each component is ammonium nitrate NH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com