Hydrogel-based solid-state up-conversion luminescence material and preparation method thereof

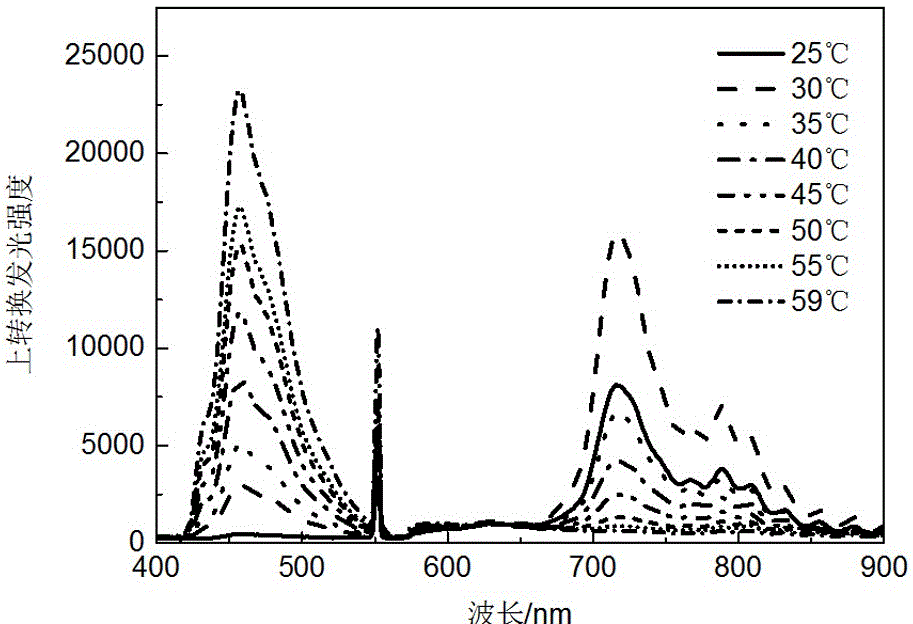

A luminescent material and hydrogel technology, applied in the field of nonlinear optical materials, can solve the problem of low quantum yield of solid-state up-conversion materials and achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of PdTPP / DPA upconversion material based on polyacrylic acid hydrogel

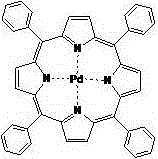

[0026] The metalloporphyrin complex used in the photosensitizer in this embodiment is PdTPP, and the molecular structure is:

[0027]

[0028] The fused-ring aromatic hydrocarbon used in the luminescent agent in this embodiment is DPA, and the molecular structure is:

[0029]

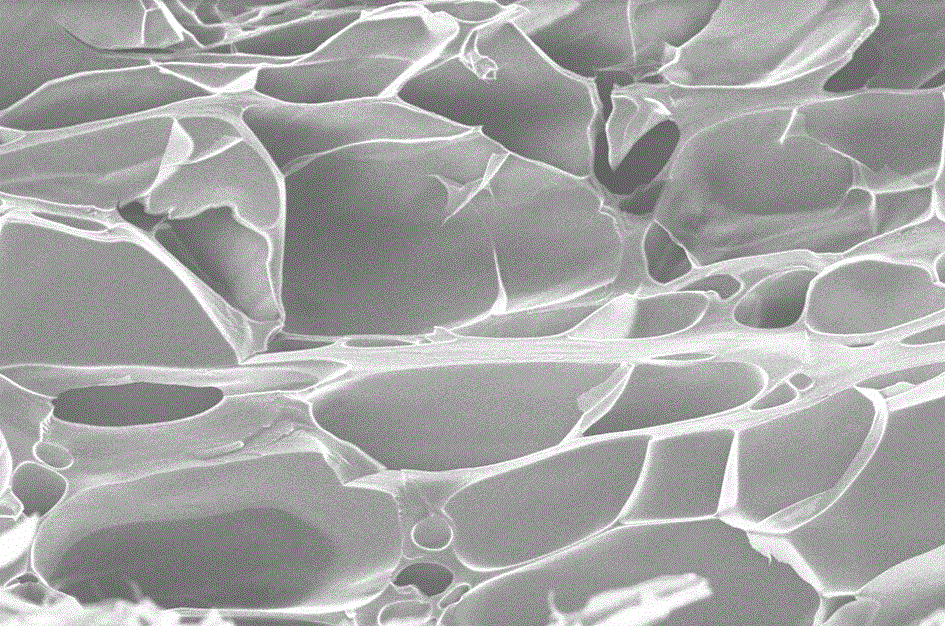

[0030] Preparation of polyacrylic acid hydrogel: add sodium hydroxide (2.32g) into a beaker containing 30mL of distilled water, stir with a glass rod until it is uniformly dissolved, slowly add acrylic acid (5mL) in an ice water bath, and then add the initiator ( KPS, 0.015g), crosslinking agent (BIS, 0.0013g), stir and mix well. Heat in a constant temperature water bath at 60°C for 3 hours, take out the translucent elastic solid, take a proper amount of the solid and soak in a beaker of distilled water after cooling, and finally obtain a porous polyacrylic acid hydrogel by the PIT method.

[0031] Under a nit...

Embodiment 2

[0034] Example 2 Preparation of PdTPP / DPA upconversion material based on polymethacrylic acid hydrogel

[0035] The photosensitizer and luminescent agent used in this embodiment are the same as in the first embodiment.

[0036] Preparation of polymethacrylic acid hydrogel: add sodium hydroxide (2.32g) into a beaker containing 30mL of distilled water, stir with a glass rod until it is uniformly dissolved, slowly add methacrylic acid (5mL) in an ice water bath, and then Add initiator (KPS, 0.015g), crosslinking agent (BIS, 0.0013g), stir and mix well. Heat in a constant temperature water bath at 50°C for 3 hours, take out the translucent elastic solid, take an appropriate amount of solid and soak in a beaker of distilled water after cooling, and finally obtain a porous polyacrylic acid hydrogel by the PIT method.

[0037] Under a nitrogen atmosphere, add the surfactant Tween-20 (10mL) to deionized water (20mL), stir to completely dissolve, and then add the luminescent agent DPA (36mM)...

Embodiment 3

[0038] Example 3 Preparation of PdTPP / DPA upconversion material based on sodium polyacrylate hydrogel

[0039] The photosensitizer and luminescent agent used in this embodiment are the same as in the first embodiment.

[0040] Preparation of sodium polyacrylate hydrogel: add sodium hydroxide (2.32g) into a beaker containing 30mL of distilled water, stir with a glass rod until it is uniformly dissolved, slowly add sodium acrylate (5g) in an ice water bath, and then add the initiator (KPS, 0.015g), crosslinking agent (BIS, 0.0013g), stir and mix well. Heat in a constant temperature water bath at 50°C for 3 hours, take out the translucent elastic solid, take a proper amount of solid and soak in a beaker of distilled water after cooling, and finally obtain porous polyacrylic acid sodium hydrogel by PIT method.

[0041] Under a nitrogen atmosphere, add the surfactant Tween-80 (8mL) to deionized water (18mL), stir to completely dissolve, and then add the luminescent agent DPA (36mM) and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com