Preparation of three-dimensional resin solution for alkaline anion exchange membrane

A technology of three-dimensional resin and alkaline anion, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of less attention on alkaline anion exchange resins, and achieve the effect of avoiding insoluble or insoluble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 1 weight unit of styrene-containing 30% SEBS triblock copolymer in 20 weight units of chloroform solvent, add 1 weight unit of anhydrous zinc chloride, and then add 15 weight units of 1,4-dichloromethane Oxybutane, stirred and reacted at 50°C for 4 hours, poured the reaction solution into ethanol, filtered, and dried to obtain a chloromethylated polymer product, and dissolved the chloromethylated polymer in 1 : in 0.5 THF / isopropanol mixed solvent, then add 1 weight unit of tripropylamine, stir and react at 40°C for 12h to obtain 5wt% Cl - Type anion exchange resin solution (SEBS-Ionomer-1).

[0022] The ion conductivity of this anion exchange resin was 28.2 mS / cm at 30°C.

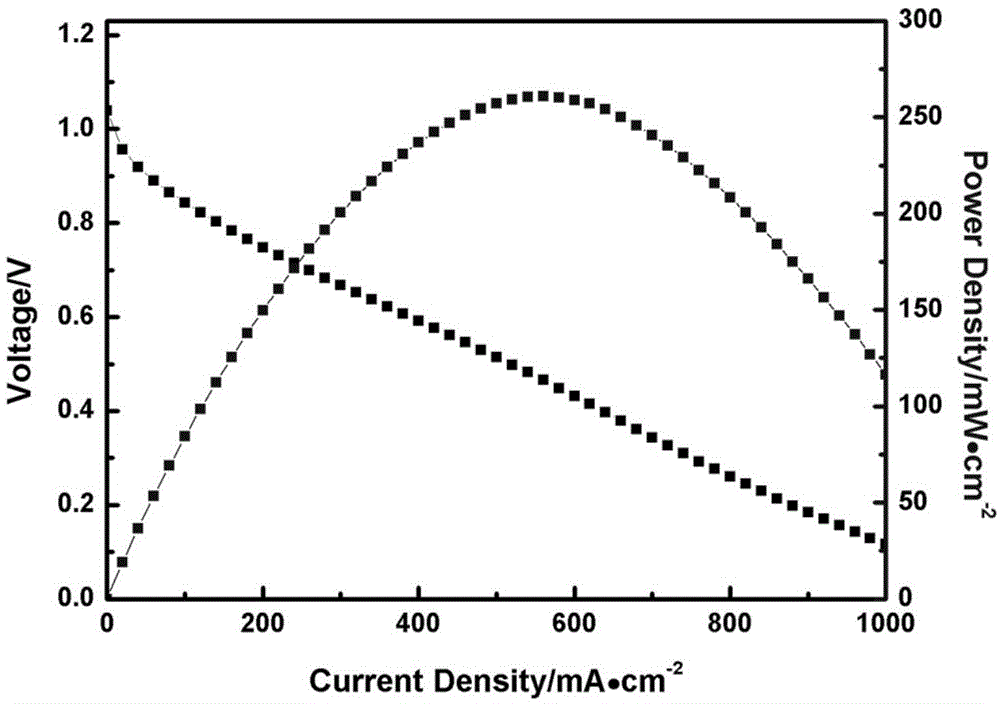

[0023] The resin is used to prepare a thin-layer film-coated electrode (CCM), and the CCM is soaked in a 1M potassium hydroxide solution for alkalization for 10 hours to obtain OH - Type CCM electrode, the performance of the electrode after assembling a single cell is as follows figure 1...

Embodiment 2

[0025] Dissolve 1 weight unit of styrene-containing 35% SEBS triblock copolymer in 50 weight units of chloroform solvent, add 1.5 weight units of anhydrous zinc chloride, and then add 25 weight units of 1,4-dichloromethane Oxybutane, stirred and reacted at 60°C for 6 hours, poured the reaction solution into ethanol, filtered, and dried to obtain a chloromethylated polymer product, and dissolved the chloromethylated polymer in 1 : in 0.7 tetrahydrofuran / ethanol mixed solvent, then add 1 weight unit of tributylamine, stir and react at 55°C for 15h, obtain 5wt% Cl - Type anion exchange resin solution (SEBS-Ionomer-2).

[0026] The ion conductivity of this anion exchange resin was 29.3 mS / cm at 30°C.

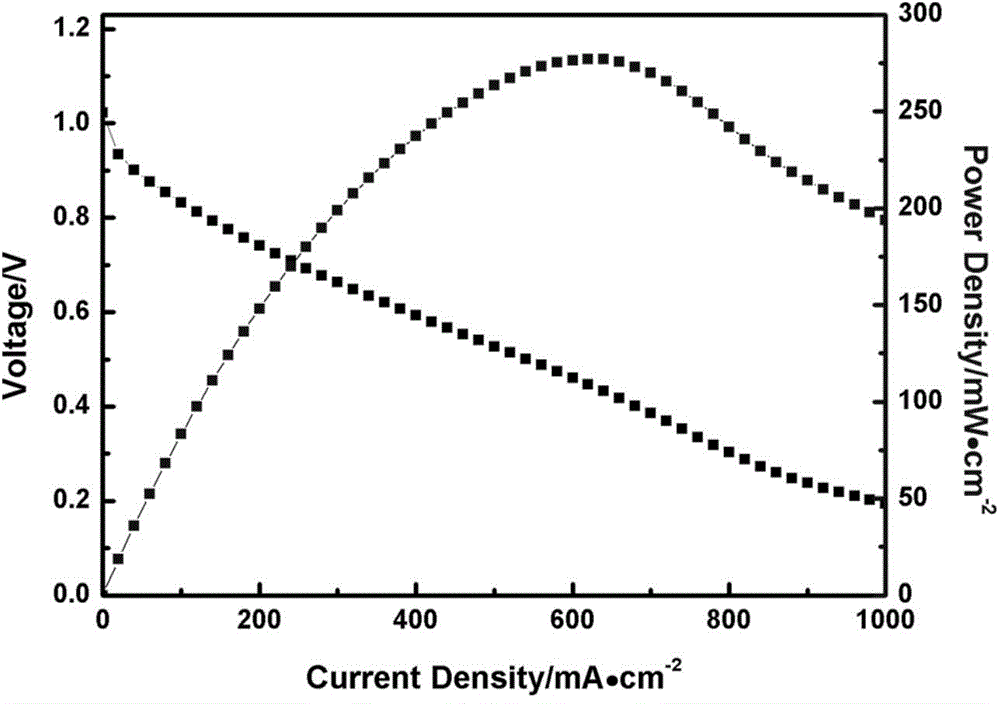

[0027] Use this resin to prepare CCM, soak CCM in 1M potassium hydroxide solution for alkalinization for 10h, and obtain OH - Type CCM electrode, the performance of the electrode after assembling a single cell is as follows figure 2 As shown, its peak power density is 278mW / cm ...

Embodiment 3

[0029] Dissolve 1 weight unit of styrene-containing 40% SEBS triblock copolymer in 150 weight units of chloroform solvent, add 2 weight units of anhydrous tin chloride, and then add 20 weight units of 1,4-dichloromethane Oxybutane, stirred and reacted at 45°C for 10 hours, poured the reaction solution into ethanol, filtered, and dried to obtain the chloromethylated polymer product, and dissolved the chloromethylated polymer at 25°C in 1 : in 0.8 THF / n-propanol mixed solvent, then add 1 weight unit of triethylamine, stir and react at 40°C for 20h, obtain 5wt% Cl - Type anion exchange resin solution (SEBS-Ionomer-3).

[0030] The ion conductivity of this anion exchange resin was 29.6 mS / cm at 30°C.

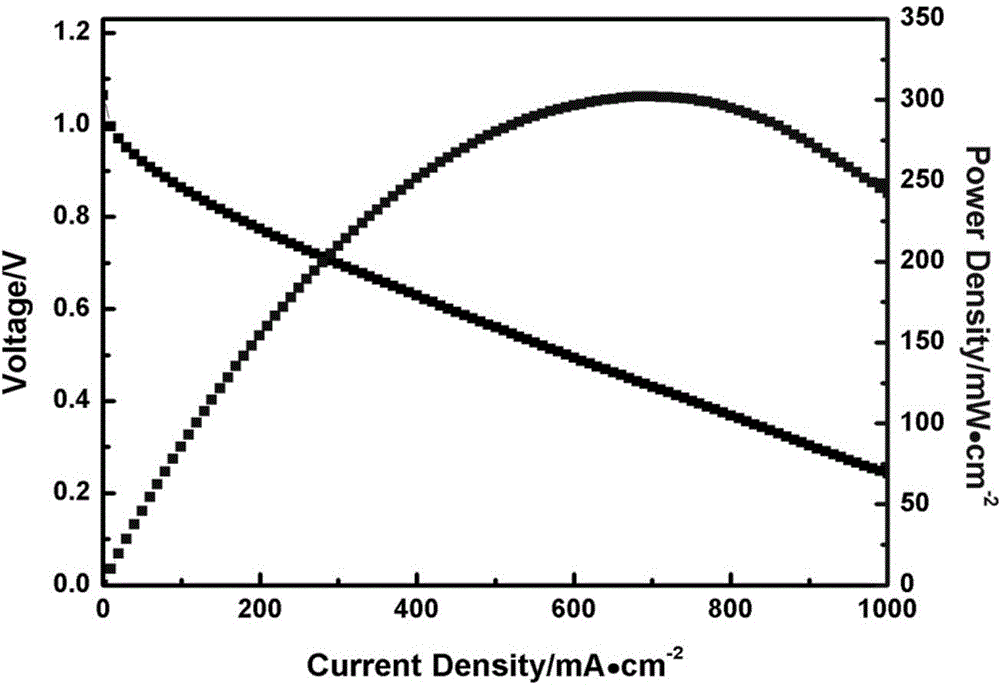

[0031] Use this resin to prepare CCM, soak CCM in 1M potassium hydroxide solution for alkalinization for 10h, and obtain OH - Type CCM electrode, the performance of the electrode after assembling a single cell is as follows image 3 As shown, the peak power density is 301mW / cm 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com