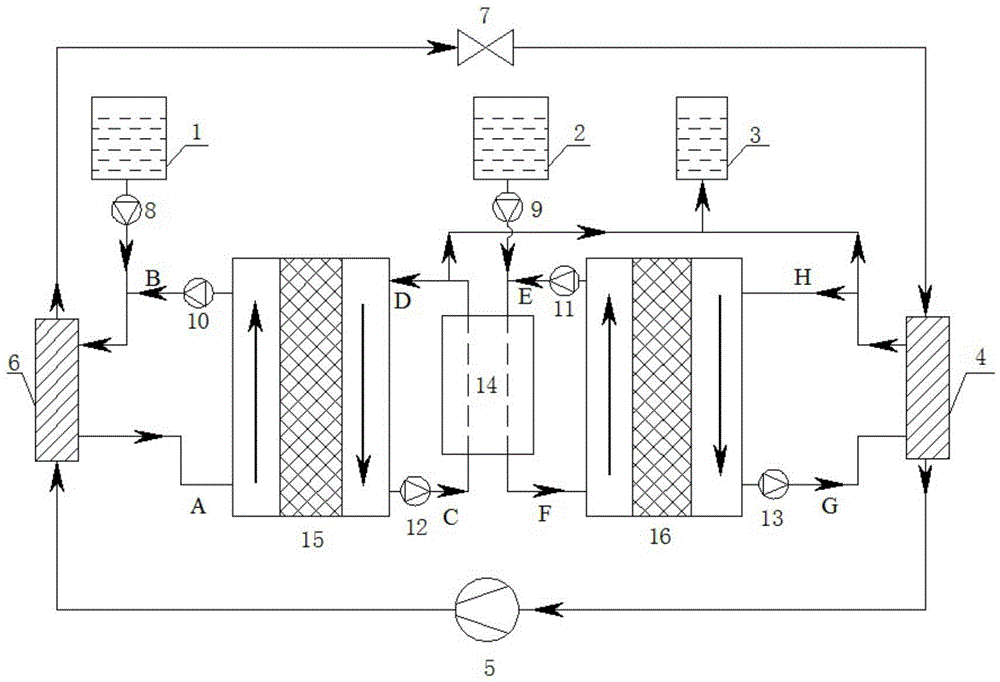

Heat pump-double-effect membrane distillation apparatus and distillation method

A technology of membrane distillation and heat pump evaporator, which is applied in the field of heat energy recovery and utilization, can solve the problems of large condensation on the cold side and high energy consumption, and achieve the effects of high heat recovery efficiency, simple equipment, and high water production ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Material liquid: seawater (index) (main component: Ca 2+ 410mg / L; Mg 2+ 1310mg / L; Na + 10900mg / L; K + 390mg / L; Ba 2+ 0.05mg / L; Cl - 19700mg / L; SO 4 2- 2740mg / L; HCO 3 - 152mg / L)

[0032] Pretreatment: 5 micron and 1 micron pp cotton to remove liquid and solid impurities

[0033] The first-effect membrane distillation membrane module is a polypropylene flat membrane module, and the inlet temperature of the hot side: 75°C

[0034] The second-effect membrane distillation membrane module is a polyvinylidene fluoride coiled membrane module, and the inlet temperature of the hot side is 65°C

[0035] Average temperature difference of heat exchanger: 5.3°C

[0036] Compressor: reciprocating piston compressor

[0037] Results: The product is distilled water, the heat recovery rate is over 90%, and the water-to-water ratio is 8.6.

Embodiment 2

[0039] Material liquid: Concentrated water from steel plant reverse osmosis (main component: Ca 2+ 320mg / L; Mg 2+ 310mg / L; Na + 46900mg / L; K + 39mg / L; Cl - 59800mg / L; NO 3 2- 2740mg / L; HCO 3 - 552mg / L)

[0040] Pretreatment: 5 micron and 1 micron pp cotton to remove liquid and solid impurities

[0041] The first effect membrane distillation membrane module is a polytetrafluoroethylene flat membrane module, the inlet temperature of the hot side: 80 ℃

[0042] The second-effect membrane distillation membrane module is a polyvinylidene fluoride hollow fiber membrane module, and the inlet temperature of the hot side: 70°C

[0043] Average temperature difference of heat exchanger: 6.1℃

[0044] Compressor: screw compressor

[0045] Results: The product is distilled water, the heat recovery rate is over 90%, and the water-to-water ratio is 6.3.

Embodiment 3

[0047] Material liquid: simulated seawater (main component: Ca 2+ 410mg / L; Mg 2+ 1310mg / L; Na + 10900mg / L; K + 390mg / L; Cl - 19700mg / L; SO 4 2- 2740mg / L)

[0048] Pretreatment: 5 micron and 1 micron pp cotton to remove liquid and solid impurities

[0049] The first-effect membrane distillation membrane module is a polypropylene hollow fiber membrane module, and the inlet temperature of the hot side: 80°C

[0050] The second-effect membrane distillation membrane module is a polytetrafluoroethylene hollow fiber membrane module, and the inlet temperature of the hot side: 70°C

[0051] Average temperature difference of heat exchanger: 8.7℃

[0052] Compressor: Rolling piston compressor

[0053] Results: The product is distilled water, the heat recovery rate is over 90%, and the water-to-water ratio is 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com