An integrated preparation method for iron separation from red mud and its tailings-based foamed lightweight wall material

A technology of red mud and tailings, applied in chemical instruments and methods, ceramic products, and other household appliances, can solve the problems of high cost of valuable metals, efflorescence of fired bricks, secondary pollution, etc., and achieve great practical value , simple preparation process and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

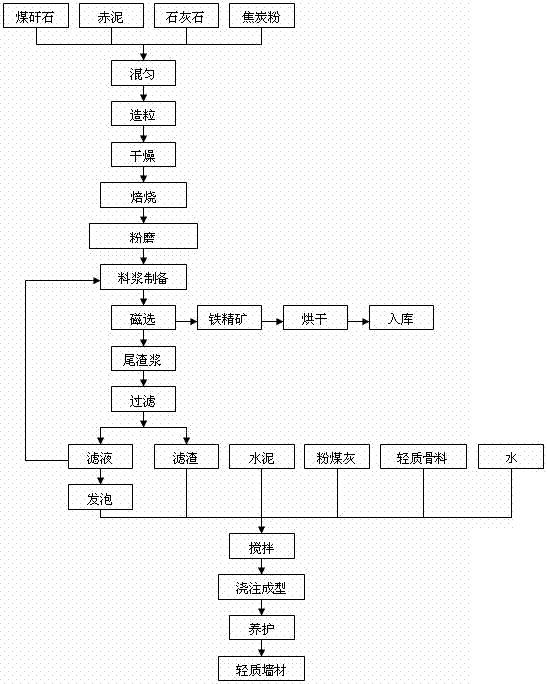

Image

Examples

Embodiment 1

[0016] An integrated method for preparing iron from red mud and its tailings-based foamed lightweight wall material, the specific implementation steps are as follows:

[0017] (1) Iron selection from red mud

[0018] Weigh 50 parts of red mud, 30 parts of coal gangue, 10 parts of limestone, and 10 parts of coke powder by weight on a dry basis, and fully and uniformly mix them in a mixer; add water, granulate, and dry; Roast at 1050°C for 2 hours, cool naturally to room temperature, and grind to 200 mesh; add water and stir to prepare a 20 wt% slurry; send the prepared slurry to a magnetic separator to select iron, and the magnetic induction is 1600Gs.

[0019] (2) Red mud slag liquid separation

[0020] The red mud tailings slurry after roasting and magnetic separation is filtered, the filtered red mud tailings are sent to the mixer, the filtrate is introduced into the filtrate pool for reuse, part of it is sent to the foaming machine for foaming, and part of it is used to pr...

Embodiment 2

[0025] An integrated method for preparing iron from red mud and its tailings-based foamed lightweight wall material, the specific implementation steps are as follows:

[0026] (1) Iron selection from red mud

[0027] Weigh 70 parts of red mud, 10 parts of coal gangue, 5 parts of limestone, and 15 parts of coke powder by weight on a dry basis, and fully and uniformly mix them in a mixer; add water, granulate, and dry; Roast at 1200°C for 4 hours, cool naturally, and grind to 200 mesh; add water to prepare a 40 wt% slurry; send the prepared slurry to a magnetic separator for iron selection, and the magnetic induction is 2800Gs.

[0028] (2) Red mud slag liquid separation

[0029] The red mud tailings slurry after roasting and magnetic separation is filtered, the filtered red mud tailings are transported to the mixer, the filtrate is introduced into the filtrate pool for reuse, part of it is sent to the foaming machine for foaming, and part of it is used to prepare new iron sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com