Novel in-situ double-sealing treatment process for full-amount recycling of landfill leachate

A technology for landfill leachate and recycling, which is applied in the treatment of polluted groundwater/leachate, water/sewage treatment, water/sludge/sewage treatment, etc. problems to relieve stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

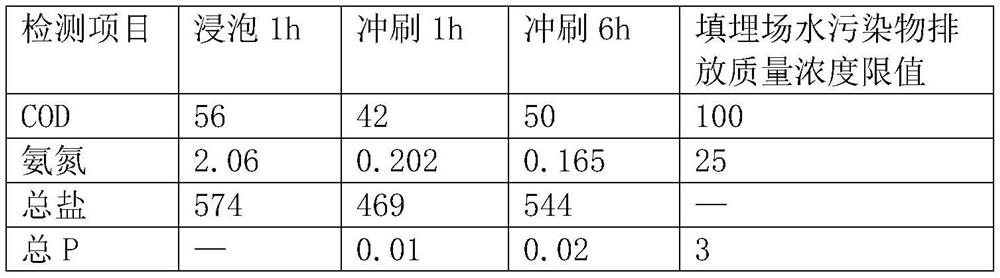

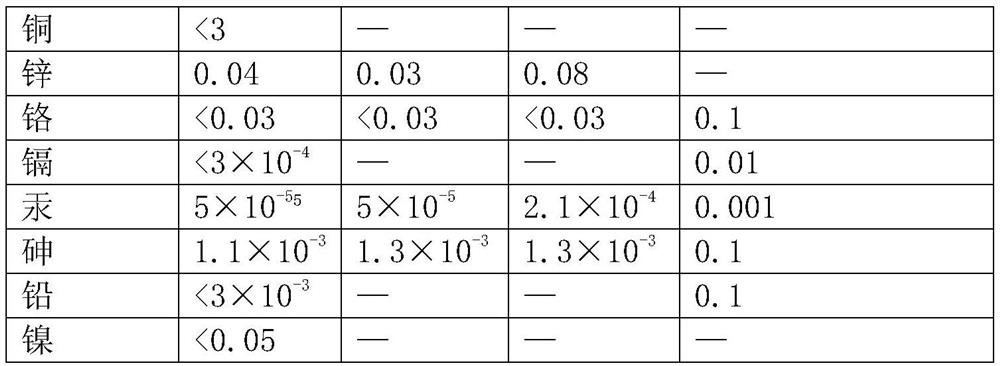

Embodiment 1

[0040] The new process of in-situ double sealing treatment of landfill leachate full resource recycling, including sealing slurry and its mixing ratio, pulping and spray sealing process;

[0041] The sealing slurry includes power plant bottom slag or slag, mixed grinding ash, cement, and curing agent powder. The content of each component in the sealing slurry is: 50 parts of power plant bottom slag or slag, 20 parts of mixed grinding ash, 20 parts of cement, 10 parts of curing agent powder, and 160 parts of landfill leachate;

[0042] Among them, the mixed grinding ash is made of fly ash and quicklime in a weight ratio of 8:2, and then mixed and ground with an ultra-fine pulverizer to a specific surface area of 700㎡ / ㎏;

[0043] Among them, the cement is 42.5 grade Portland cement;

[0044] Among them, the curing agent powder contains cement ultra-fast hardening agent, active waste residue activator, heavy metal complexing agent, adsorbent, waterproofing agent, and slurry ta...

Embodiment 2

[0053] The new process of in-situ double sealing treatment of landfill leachate full resource recycling, including sealing slurry and its mixing ratio, pulping and spray sealing process;

[0054] The sealing slurry includes power plant bottom slag or slag, mixed grinding ash, cement, and curing agent powder. The content of each component in the sealing slurry is: 55 parts of power plant furnace bottom slag or slag, 25 parts of mixed grinding ash, 15 parts of cement, 5 parts of curing agent powder, 200 parts of landfill leachate;

[0055] Among them, the mixed grinding ash is made of fly ash and quicklime in a weight ratio of 9:1, and then mixed and ground with an ultra-fine pulverizer to a specific surface area of 600㎡ / ㎏;

[0056] Among them, the cement is 32.5 grade Portland cement;

[0057] Among them, the curing agent powder contains cement ultra-fast hardening agent, active waste residue activator, heavy metal complexing agent, adsorbent, waterproofing agent, and slurry...

Embodiment 3

[0066] The new process of in-situ double sealing treatment of landfill leachate full resource recycling, including sealing slurry and its mixing ratio, pulping and spray sealing process;

[0067] The sealing slurry includes power plant bottom slag or slag, mixed grinding ash, cement, and curing agent powder. The content of each component in the sealing slurry is: 60 parts of power plant bottom slag or slag, 20 parts of mixed grinding ash, 16 parts of cement, 4 parts of curing agent powder, and 250 parts of landfill leachate;

[0068] Among them, the mixed grinding ash is made of fly ash and quicklime in a weight ratio of 8:2, and then mixed and ground with an ultra-fine pulverizer to a specific surface area of 500㎡ / ㎏;

[0069] Among them, the cement is 32.5 grade Portland cement;

[0070] Among them, the curing agent powder contains cement ultra-fast hardening agent, active waste slag activator, heavy metal complexing agent, adsorbent, water repellent, and slurry thickening a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com