An anti-scald, safe, low-pressure, environment-friendly hydrogen generator and gas preparation method

A hydrogen and safe technology, applied in the field of gas preparation, can solve problems such as potential safety hazards, potential safety hazards of scalding operators, environmental pollution, etc., and achieve full inflation effect, good inflation effect and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

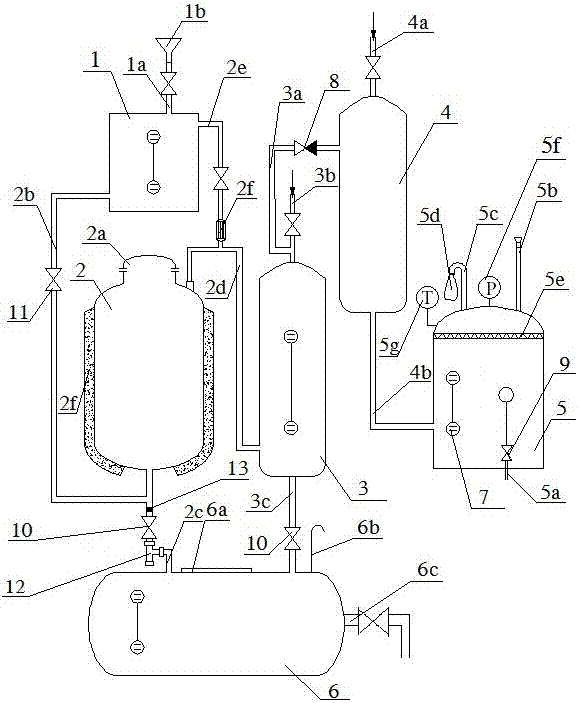

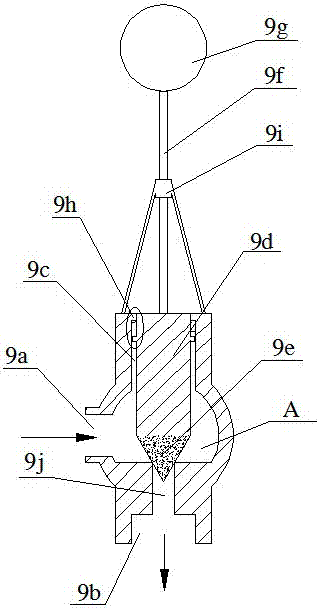

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 and figure 2 As shown, an anti-scalding, safe, low-pressure, environment-friendly hydrogen generator includes: a liquid inlet 1, a reactor 2, a purifier 3, a gas-water mixing cooler 4, a gas-water separator 5 and a sewage storage tank 6; The top of the reactor 2 is provided with a feed inlet with a top cover 2a, flange connection between the top cover 2a and the feed inlet, and a thermal insulation layer 2f is provided on the peripheral wall of the reactor 2, which is mainly due to A large amount of heat of reaction is generated, which heats up the outer wall of the reactor. The use of the heat insulation layer can prevent the user from being burned, and secondly, the heat preservation of the reactor is also conducive to speeding up the reaction speed and making the reaction more complete.

[0032] The bottom of the reactor is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com