Core/shell-type micropore /mesoporous composite titanium silicon molecular sieve and preparation method thereof

A silicon molecular sieve and composite titanium technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable guest molecular diffusion, etc., and achieve the effects of strong controllability, regular structure, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

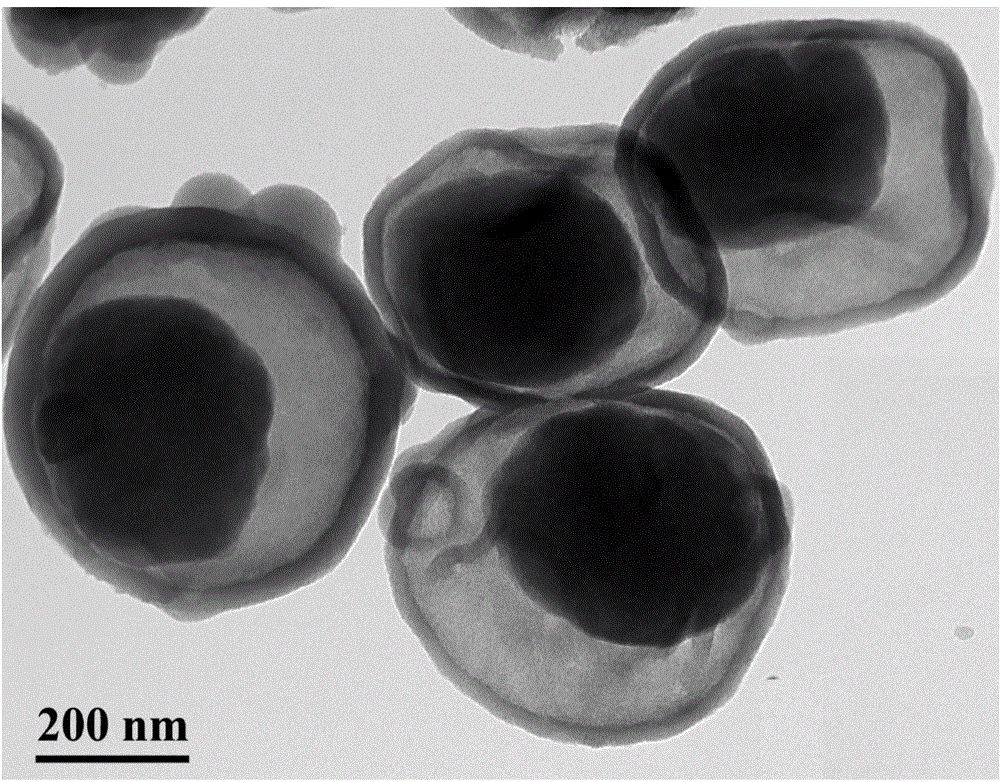

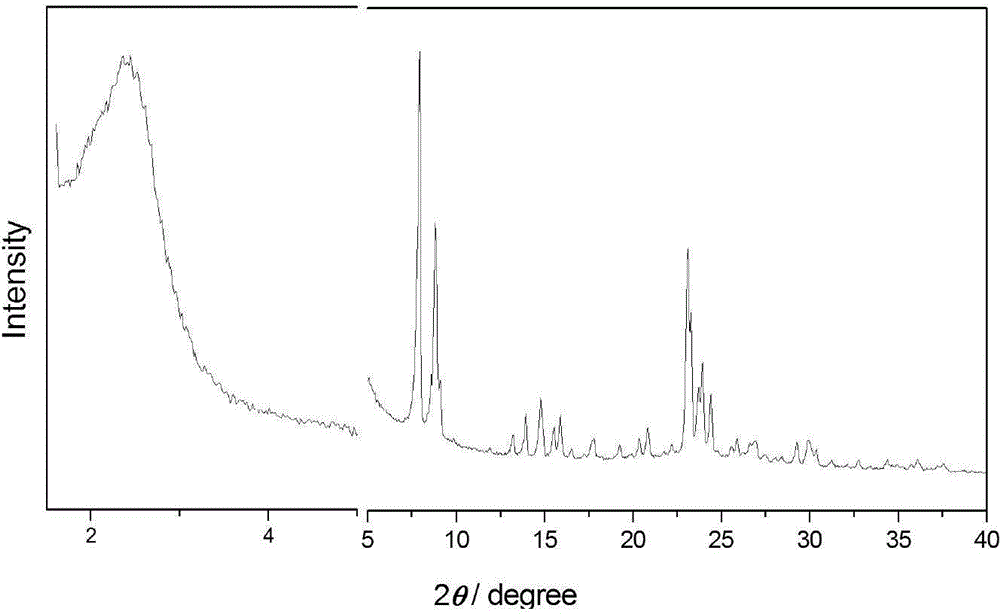

Embodiment 1

[0018] Take 0.25g of microporous titanium-silicon molecular sieve TS-1 and disperse it in 40ml of deionized water and 20ml of absolute ethanol, add 0.5g of cetyltrimethylammonium bromide and 0.3g of ammonia water, stir for 0.5h, add 0.05g of m-benzene Diphenol and 0.075g of formaldehyde solution with a mass concentration of 37% were continuously stirred at room temperature for 8 hours, left to stand for 14 hours, the product was filtered out, and dried at 80°C to obtain a microporous titanium-silicon molecular sieve TS-1 coated with a phenolic resin polymer. (TS-1RF). Disperse 0.5g of TS-1RF in 100ml of deionized water and 60ml of absolute ethanol, add 0.05g of cetyltrimethylammonium bromide and 2g of ammonia water, stir at 40°C for 0.5h, add 0.57g of tetraethylsilicate and 0.018 g of n-tetrabutyl titanate, continuously stirred for 15 hours, filtered, dried at 80° C., and calcined at 550° C. for 5 hours in an air atmosphere to obtain a core / shell microporous / mesoporous composi...

Embodiment 2

[0020] Take 0.25g of microporous titanium-silicon molecular sieve TS-1 and disperse it in 40ml of deionized water and 20ml of absolute ethanol, add 0.5g of cetyltrimethylammonium bromide and 0.3g of ammonia water, stir for 0.5h, add 0.1g of m-benzene Diphenol and 0.15g of formaldehyde solution with a mass concentration of 37% were continuously stirred at room temperature for 8 hours, left to stand for 14 hours, filtered out the product, and dried at 80°C to obtain a microporous titanium-silicon molecular sieve TS-1 coated with a phenolic resin polymer (TS-1RF). Disperse 0.5g of TS-1RF in 100ml of deionized water and 60ml of absolute ethanol, add 0.05g of cetyltrimethylammonium bromide and 2g of ammonia water, stir at 40°C for 0.5h, add 0.57g of tetraethylsilicate and 0.018 g of n-tetrabutyl titanate, continuously stirred for 15 hours, filtered, dried at 80° C., and calcined at 550° C. for 5 hours in an air atmosphere to obtain a core / shell microporous / mesoporous composite tita...

Embodiment 3

[0022] Take 0.25g of microporous titanium-silicon molecular sieve TS-1 and disperse it in 40ml of deionized water and 20ml of absolute ethanol, add 0.5g of cetyltrimethylammonium bromide and 0.3g of ammonia water, stir for 0.5h, add 0.2g of m-benzene Diphenol and 0.3g of formaldehyde solution with a mass concentration of 37% were continuously stirred at room temperature for 8 hours, left to stand for 14 hours, filtered out the product, and dried at 80°C to obtain a microporous titanium-silicon molecular sieve TS-1 coated with a phenolic resin polymer (TS-1RF). Disperse 0.5g of TS-1RF in 100ml of deionized water and 60ml of absolute ethanol, add 0.05g of cetyltrimethylammonium bromide and 2g of ammonia water, stir at 40°C for 0.5h, add 0.57g of tetraethylsilicate and 0.018g of n-tetrabutyl titanate, continuously stirred for 15h, filtered, dried at 80°C, and calcined at 550°C for 5h in an air atmosphere to obtain a core / shell microporous / mesoporous composite titanium-silicon mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com