Method for improving sludge settling performance in low-concentration zinc-containing wastewater treatment process

A technology for wastewater treatment and sludge settling, applied in the field of environmental engineering, can solve problems such as poor settling performance and small sludge size, and achieve the effects of improving settling compression performance, simple equipment and improving sludge settling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

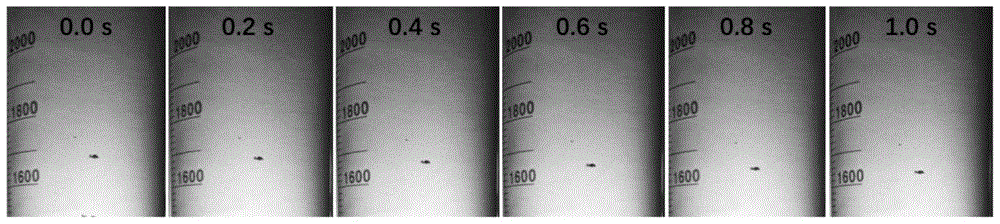

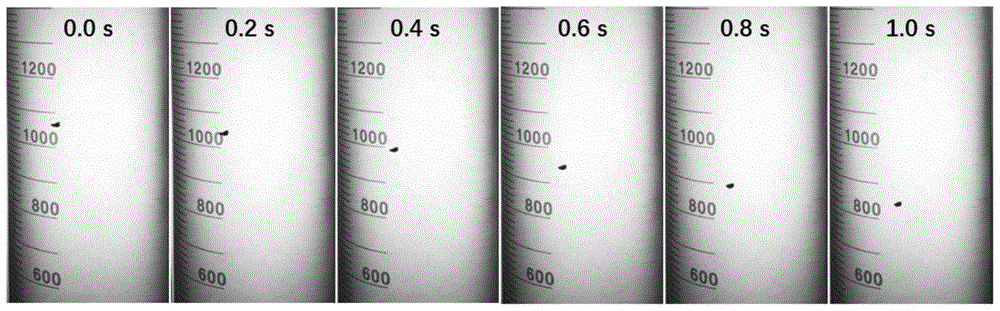

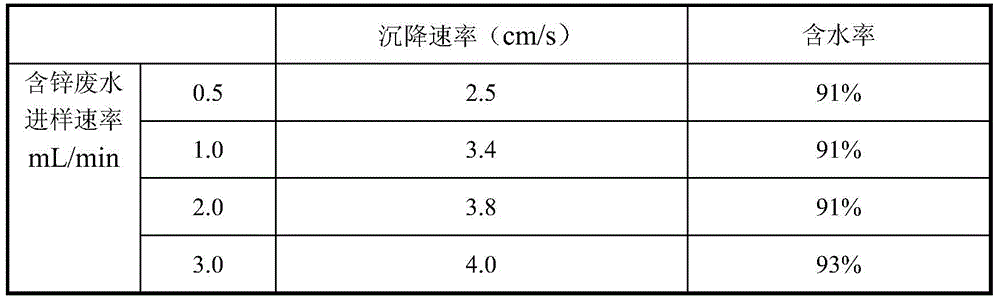

[0021] The 1000mL reaction beaker was placed on a constant temperature magnetic stirring device, the temperature was controlled at 25°C, and the stirring rate was adjusted to 200rpm. 100 mL of the suspension containing ZnO nanoparticles (2.5 g / L) was added to the reaction beaker. Then drop sodium hydroxide solution (0.03mol / L) and low-concentration zinc-containing waste water (zinc ion concentration 50mg / L) respectively in the beaker simultaneously, control the drop rate rate of low-concentration zinc-containing waste water to be 3.5mL / min, by The sodium hydroxide solution controls the reaction pH value to 9.0±0.2, and reacts for 1 hour. A 0.1% polyacrylamide (PAM) flocculant was added to the suspended solution system after the above reaction to make the reaction concentration 15 mg / L. Then stir rapidly (500rpm) for 30s, and then stir slowly (50rpm) for 15min. Stand still for 30 minutes to stabilize and completely settle the sludge. The removal rate of zinc ions in this pro...

Embodiment 2

[0023] The 1000mL reaction beaker was placed on a constant temperature magnetic stirring device, the temperature was controlled at 15°C, and the stirring rate was adjusted to 100rpm. Add 100 mL of the ZnO nanoparticle-containing suspension (3.0 g / L) to the reaction beaker. Then drop sodium hydroxide solution (0.05mol / L) and low-concentration zinc-containing wastewater (zinc ion concentration 50mg / L) respectively in the beaker simultaneously, control the dropping rate of low-concentration zinc-containing wastewater to 5mL / min, pass hydrogen The sodium oxide solution controls the reaction pH value to 9.0±0.2, and reacts for 1 hour. A 0.1% polyacrylamide (PAM) flocculant was added to the suspended solution system after the above reaction to make the reaction concentration 15 mg / L. Then stir rapidly (500rpm) for 30s, and then stir slowly (50rpm) for 15min. Stand still for 30 minutes to stabilize and completely settle the sludge. The removal rate of zinc ions in this process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com