Preparation method of GaN-based light-emitting diode chip

A technology of light-emitting diodes and chips, which is applied in the field of optoelectronics and can solve the problems of small electrode line width lithography machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preparation method of the GaN-based light-emitting diode chip of the present invention, the specific steps are as follows:

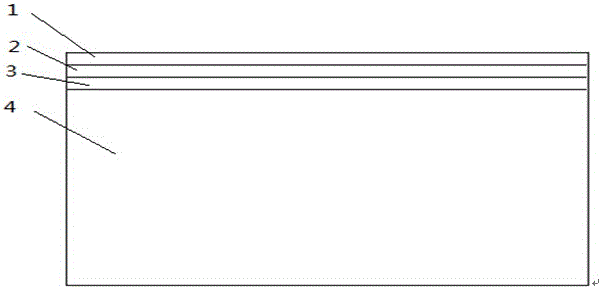

[0035] (1) if figure 1 As shown, an ITO transparent conductive film 1 with a thickness of 700-3000 angstroms is vapor-deposited on the upper surface of the p-type GaN layer 2 of the GaN-based light-emitting diode chip. The GaN-based light-emitting diode chip includes an n-type GaN layer 4 , a quantum well layer 3 and a p-type GaN layer 2 arranged from bottom to top.

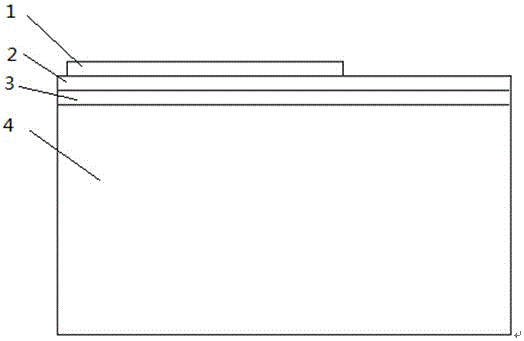

[0036] Uniform positive photoresist on the surface of the transparent conductive film 1, the thickness of the photoresist is 7000-30000 angstroms, through alignment, exposure, development and drying, and then put the chip into the ITO etching solution to corrode the mesa pattern of the transparent conductive layer (Current expansion layer graphics), that is, small table graphics, such as figure 2 Shown, rinse with water and dry, and then remove the positive photoresist.

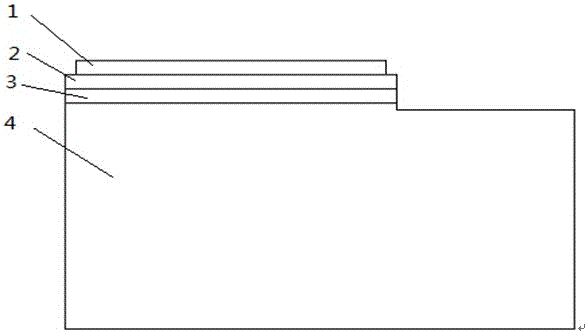

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com