A kind of denitrification catalyst of macroporous-mesoporous TIO2 doped transition metal and preparation method thereof

A denitrification catalyst and transition metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem that the production process is not easy to form and demould, and the porosity is not ideal , large amount of catalyst and other problems, to achieve the effect of increasing denitrification catalytic performance, improving circulation and diffusion performance, and easy to repeat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

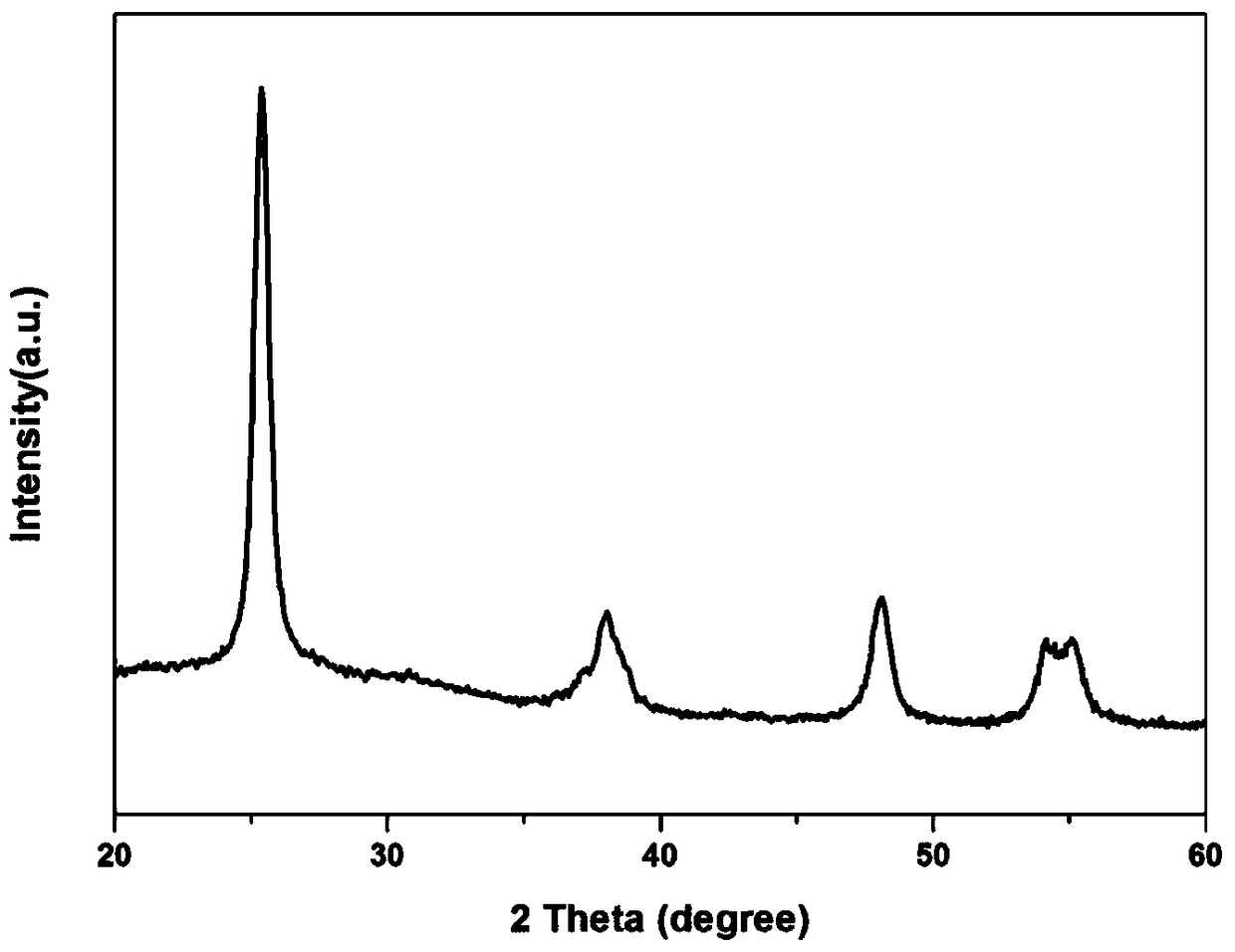

[0042] A macroporous-mesoporous TiO 2 The denitration catalyst doped with transition metal, its preparation method comprises the following steps:

[0043] Add 20ml of ammonia water with a mass fraction of 25% to the beaker, add 100ml of deionized water to the ammonia water for dilution, stir for 5 minutes and mix well to obtain an ammonia solution with a mass fraction of 5%; add 5ml of titanic acid to the ammonia solution at a constant speed Isopropyl ester solution (98wt%), a white precipitate was formed immediately, the precipitate was washed three times, placed in a 60°C oven, and left for 12h to obtain a white powder, which is macroporous-mesoporous TiO 2 Material.

[0044] Fully dissolve 0.156g of manganese nitrate tetrahydrate in 30ml of deionized water, and after stirring for 5min, add 2g of the macroporous-mesoporous TiO prepared above into the beaker. 2 , continue to stir for 2h (30°C), and then place the entire system in a 100°C oven for 24h. The obtained sample w...

Embodiment 2

[0047] A macroporous-mesoporous TiO 2 The denitration catalyst doped with transition metal, its preparation method comprises the following steps:

[0048] Add 20ml of ammonia solution whose mass fraction is 25% in the beaker, then add 100ml of deionized water to the ammonia solution to dilute, stir for 5min and mix well, get the ammonia solution and evenly add 5ml of isopropyl titanate solution to the ammonia solution ( 98wt%), a white precipitate was formed immediately, the precipitate was washed three times, placed in an oven at 60 °C, and allowed to stand for 12 h to obtain a white powder, which is macroporous-mesoporous TiO 2 Material.

[0049] Fully dissolve 0.47g of manganese nitrate tetrahydrate in 30ml of deionized water, stir for 5min, add 2g of the macroporous-mesoporous TiO prepared above into the beaker 2 , continue to stir for 2h (30°C), and then place the whole system in a 100°C oven for 24h. The obtained sample was taken out and placed in a muffle furnace for...

Embodiment 3

[0052] A macroporous-mesoporous TiO 2 The denitration catalyst doped with transition metal, its preparation method comprises the following steps:

[0053] Add 20ml of ammonia water with a mass fraction of 25% to the beaker, add 100ml of deionized water to the ammonia water for dilution, stir for 5 minutes and mix well to obtain an ammonia solution with a mass fraction of 5%; add 5ml of titanic acid to the ammonia solution at a constant speed Isopropyl ester solution (98wt%), a white precipitate was formed immediately, the precipitate was washed three times, placed in a 60°C oven, and left for 12h to obtain a white powder, which is macroporous-mesoporous TiO 2 Material.

[0054] Fully dissolve 0.783g of manganese nitrate tetrahydrate in 30ml of deionized water, and after stirring for 5min, add 2g of the macroporous-mesoporous TiO prepared above into the beaker. 2 , continue to stir for 2h (30°C), and then place the entire system in a 100°C oven for 24h. The obtained sample w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com